Whenever we hear bold claims like a 25 percent reduction in fuel consumption brought about by a very innovative idea, we’re always skeptical, as one needs to be in these situations, as discernment is important and it needs to stay balanced for us to make the best decisions.

However, when a big name like Volvo makes such a claim, and backs it up with reasonably detailed information, one has to pay closer attention, right?

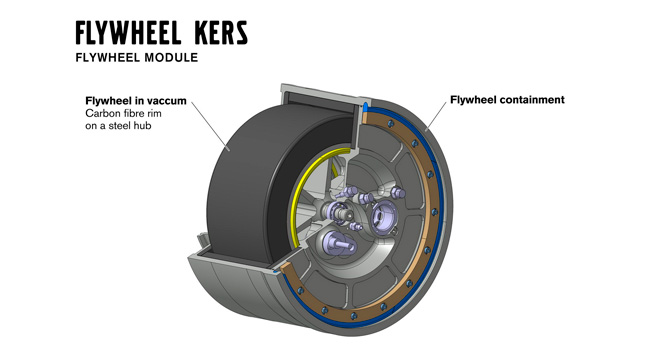

So, how are they improving fuel efficiency by up to 25 percent? Well, Volvo’s solution is KERS – kinetic energy recovery system. Their system, known as Flywheel KERS, “is fitted to the rear axle. During retardation, the braking energy causes the flywheel to spin at up to 60,000 revs per minute. When the car starts moving off again, the flywheel’s rotation is transferred to the rear wheels via a specially designed transmission.”

This is complimented by the fact that the internal combustion engine (ICE) shuts off as soon as the driver applies the brakes, so that the energy of the flywheel can be stored and then used when the car sets off again. The Swedes claim the system works best in city traffic, because “the flywheel’s stored energy is sufficient to power the car for short periods,” and this allows the engine to be turned off for around half of the entire driving time. It is a system specifically designed to work at its most efficient in stop-start traffic.

What’s even more interesting is that the system can also boost performance, and the S60 test car they used could reach 62 mph or 100 km/h in 5.5 seconds, though it was not mentioned what ICE engine was used in the prototype.

Volvo has been working on “flywheel propulsion assistance” since the 1980s, when they first fitted the system to a 260 model. However, being made of steel, it was deemed too heavy and the idea was put to the side. Now, the new experimental unit is made out of carbon fiber, has a diameter of 20 cm (7.9 inches) and weighs considerably less, at around six kilos (13 pounds).

By Andrei Nedelea

PHOTO GALLERY