During its ongoing 10-year run, the GT-R, although an incredibly capable machine to begin with, has evolved considerably in the precise performance machine that it is today.

Nevertheless, even if most parts were either changed or tweaked along the way, its engine building process remained, more or less, the same.

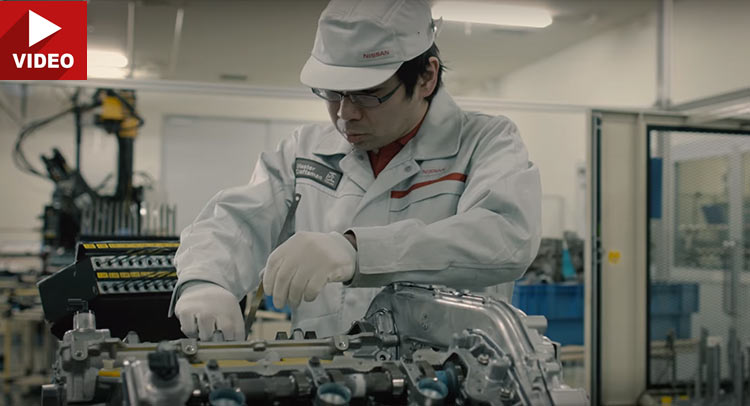

As you might recall, Nissan made quite a big fuss about building its awe-inspiring engine by hand, with only five master craftsmen called Takumi being allowed to handle the process.

This stands true for the recently unveiled new model. Each individual 3.8-litre twin-turbo V6 is assembled by one of the Takumis, as the artisans have more than 100 years of experience between them and have learned how to inspect parts for quality with microscopic precision, guaranteeing precise fitments for every engine build.

Takumi Kurosawa leads the team that assembles the powerplants in the “clean room” of Nissan’s Yokohama plant. Each VR38DETT takes about six hour to put together, and once the work is completed the Takumi craftsman proudly mounts a plaque bearing his name upon the “masterpiece”. See for yourself…