Tesla Motors and Panasonic Corporation signed off a deal to cooperate on the construction of the Gigafactory, a large-scale battery manufacturing plant to be built in the States.

As part of the deal, Tesla will prepare, provide and manage the land, buildings and utilities, while Panasonic will manufacture and supply cylindrical lithium-ion cells and invest in the associated equipment, machinery, and other manufacturing tools based on their mutual approval.

The agreement also mentions a network of supplier partners to produce the required precursor materials. Tesla will take the cells and other components to assemble battery modules and packs. To meet the estimated demand for cells, Tesla will continue to buy battery cells produced in Panasonic’s factories in Japan. The two companies will continue to discuss the details of implementation including sales, operations and investment.

The Gigafactory will be managed by Tesla with Panasonic joining as the principle partner responsible for lithium-ion battery cells and occupying approximately half of the planned manufacturing space. Key suppliers combined with Tesla’s module and pack assembly will make up the other half of the fully integrated industrial complex.

The two partners expect to achieve cost reductions through “optimized manufacturing processes driven by economies of scale previously unobtainable in battery cell and pack production.”

In a statement, the two companies said that further price reductions will be achieved by manufacturing cells that have been optimized for electric vehicle design, by co-locating suppliers on-site to eliminate packaging, transportation, duty costs and inventory carrying costs, and by manufacturing at a location with lower utility and operating expenses.

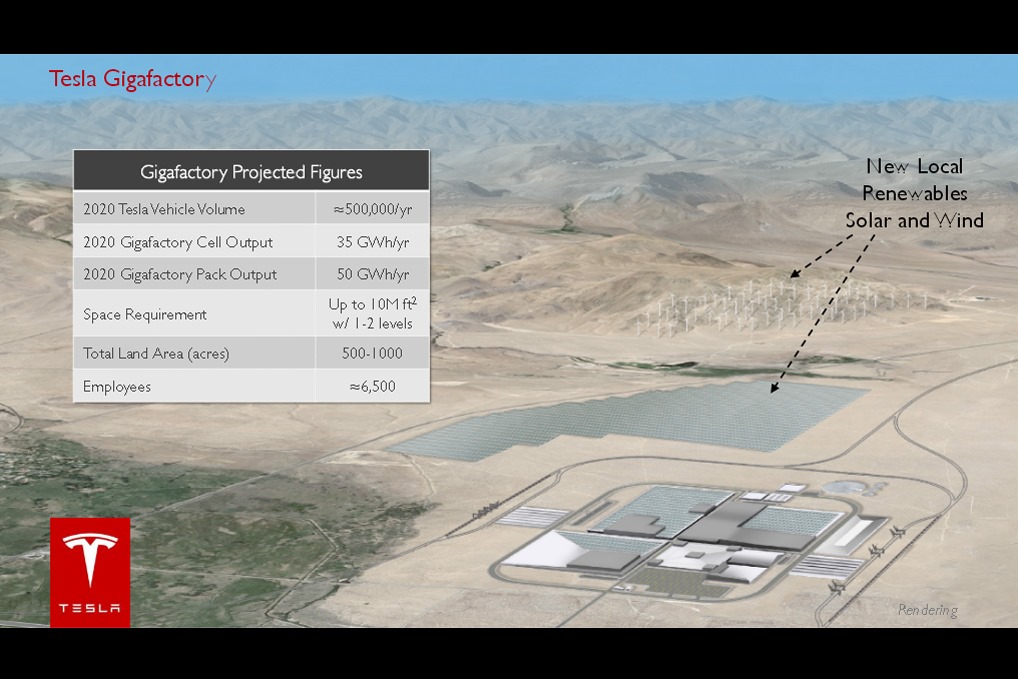

The plant will produce cells, modules and packs for Tesla’s electric vehicles and for the stationary storage market. By 2020, the Gigafactory is planned to produce 35GWh of cells and 50GWh of packs per year. Tesla projects that the Gigafactory will employ about 6,500 people by 2020.

By Dan Mihalascu