It’s no secret that Tesla is faced with poor quality control issues, especially with the Model 3 the production rates of which are a main concern for the company even today.

With more and more customer Model 3 cars being delivered, complaints on their poor quality control are increasing and now we get a closer look at what’s wrong, thanks to the trained eye of Twitter user Brian Gluckman.

Gluckman, who claims he has 15 years in automotive quality control, inspected a Model 3 show car and revealed his concerns in a series of tweets that since have gone viral.

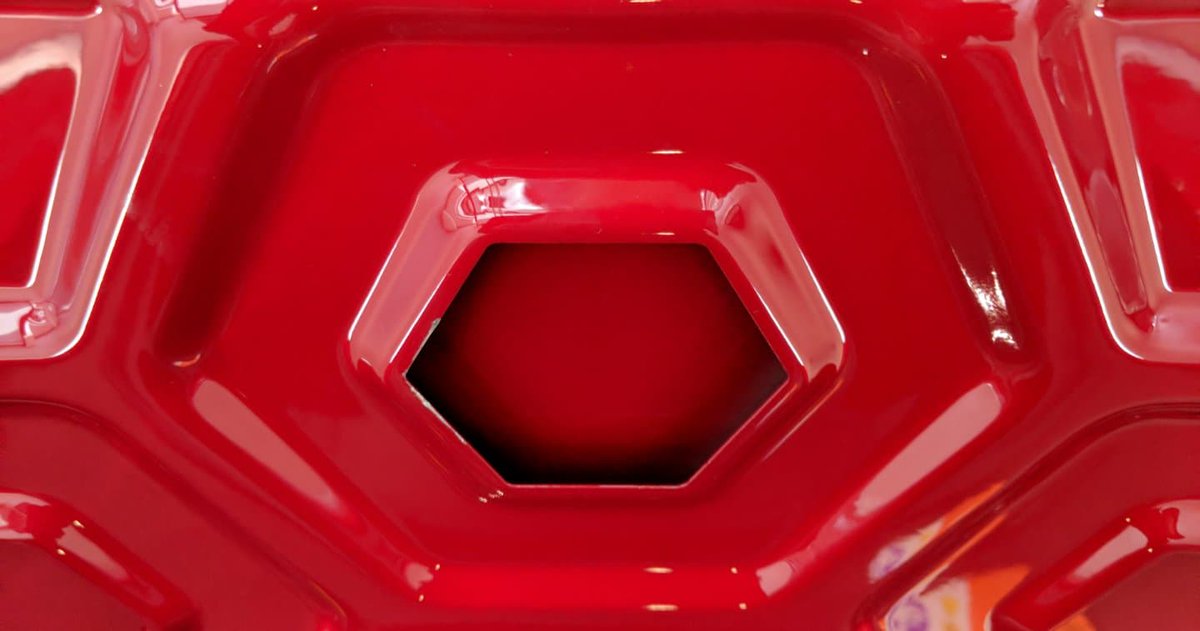

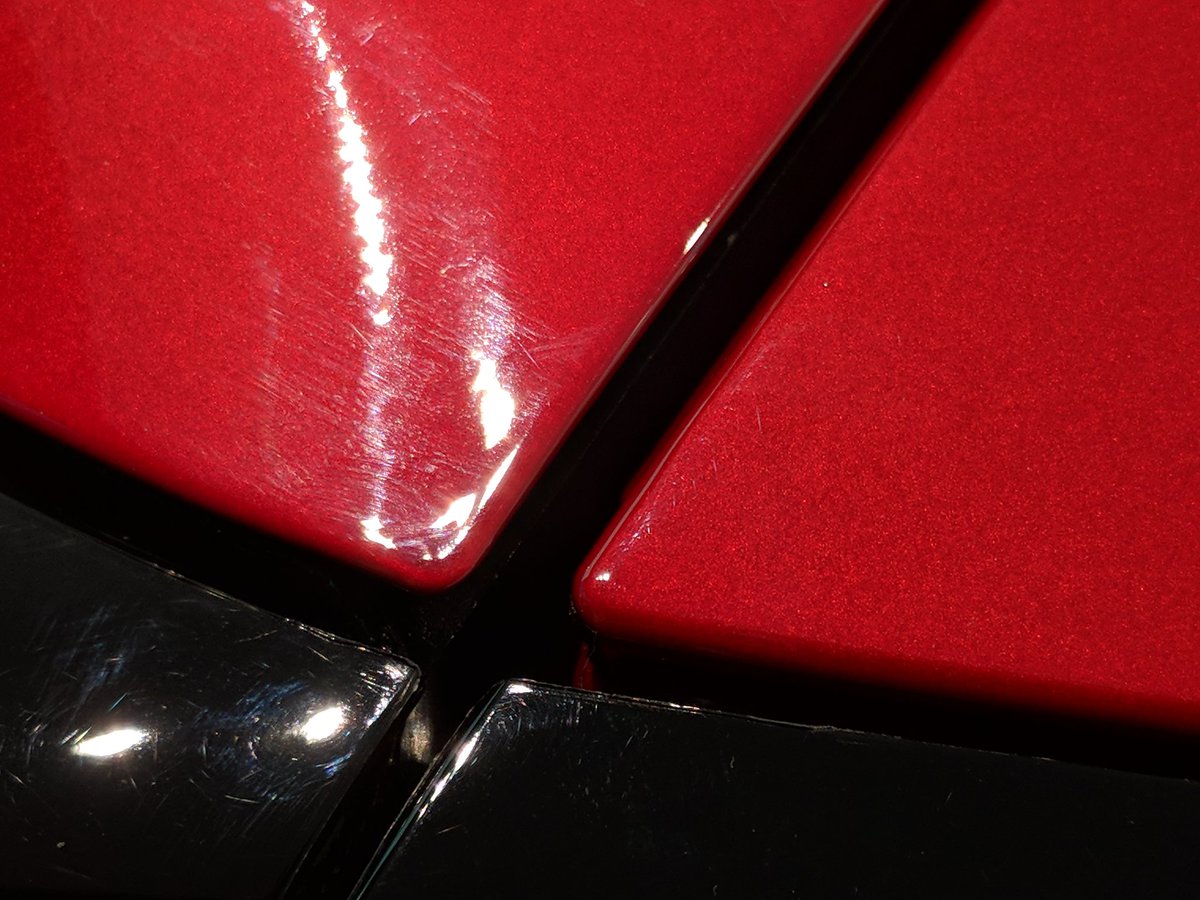

He found problems in many areas, including the panel gaps, the finish of the leather upholstery, the fitment and design of various plastic trims inside and out as well as the quality of the paintjob, which on the car he inspected, shows signs of pooling as well as chip marks.

He even discovered that the trunk ceiling is basically unpainted and unfinished metal that features a fabric screen instead of the usual soundproofing you would normally find in a car of this price range.

It’s not clear yet if the car in question is an early production Model 3 or Release Candidate model as Tesla calls them, which would explain at least some of these issues. Actual customer cars are reportedly much better in many of these areas but still owners complain about things like the fitment of the body panels and the paint quality.

Tesla’s decision to skip beta development cars and go straight to early-release Model 3s might be the main reason why these quality control issues have showed up in the first place.

Just saw my first Tesla Model 3 up close and in-person. Having spent 15 years off and on in the automotive quality space, this is…not good. pic.twitter.com/DKWJ0JXvNG

— Brian Gluckman (@bgluckman) February 19, 2018

Photo Credits: Brian Gluckman