General Motors has been introducing a handful of vehicles that are lighter than their predecessors and this trend will likely continue thanks to a partnership with Autodesk.

As the company explains, they are the first automaker in North America to use Autodesk’s new generative design software which is “key to developing efficient and lighter alternative propulsion and zero emission vehicles.” GM goes on to say the software uses AI-based algorithms to rapidly explore multiple different part designs based on a series of user set parameters such as weight, strength, material and fabrication method.

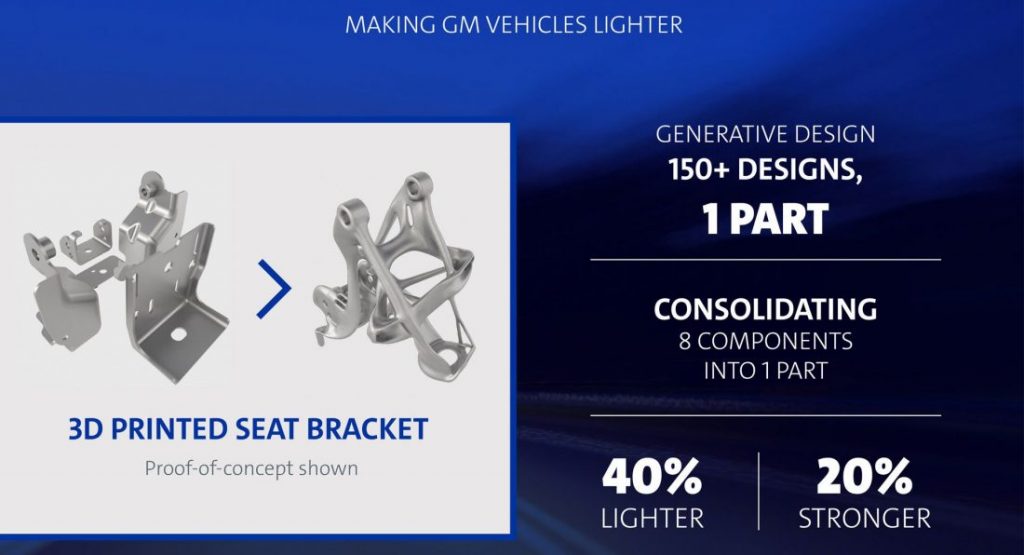

The software generates hundreds of different designs and many of them are often an “organic-looking geometric design.” After the process is completed, an engineer determines the best possible part design.

According to GM’s vice president of global vehicle components and subsystems, Ken Kelzer, “This disruptive technology provides tremendous advancements in how we can design and develop components for our future vehicles to make them lighter and more efficient.” Thanks to the software and advances in 3D printing, GM can produce unique designs which consolidate several different components and significantly reduce weight.

As a proof of concept, GM and Autodesk engineers created a seat bracket using the software. While this doesn’t sound too hard to design, the company notes the bracket created by the software was 40 percent lighter and 20 percent stronger than the original part. It also consolidated eight different components into a single 3D-printed part.

GM has made reducing weight a key priority and the company notes since 2016, they have launched 14 new vehicles which have an average weight savings of more than 350 lbs (158 kg). In particular, the 2019 Chevrolet Silverado weighs up to 450 lbs (204 kg) less than the outgoing truck.