Volkswagen is providing an insight into its Modular Electric Matrix (MEB) platform during a media event in Dresden.

As part of a newly-launched “Electric For All” campaign, MEB will underpin 27 new electric vehicles from the Group by the end of 2022 and will play an essential part in VW’s plan to put “attractive models at affordable prices on the road.”

VW is adamant that MEB is not a retroactively modified ICE platform, but has been designed from the outset to be “100 percent, uncompromisingly electric.”

The new architecture will allow VW to roll out its electric offensive, starting with the ID electric hatchback that will enter production in Zwickau by the end of 2019.

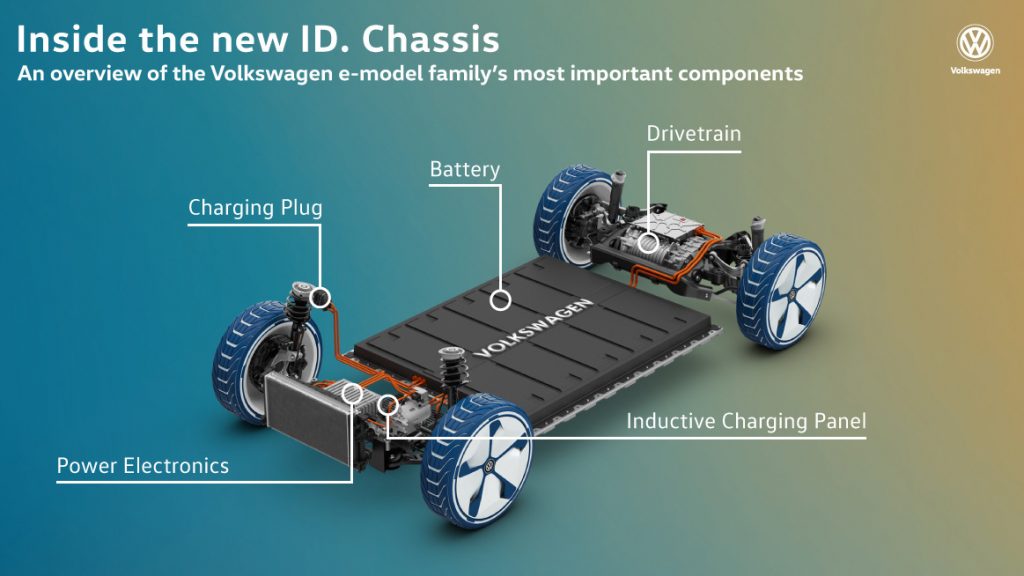

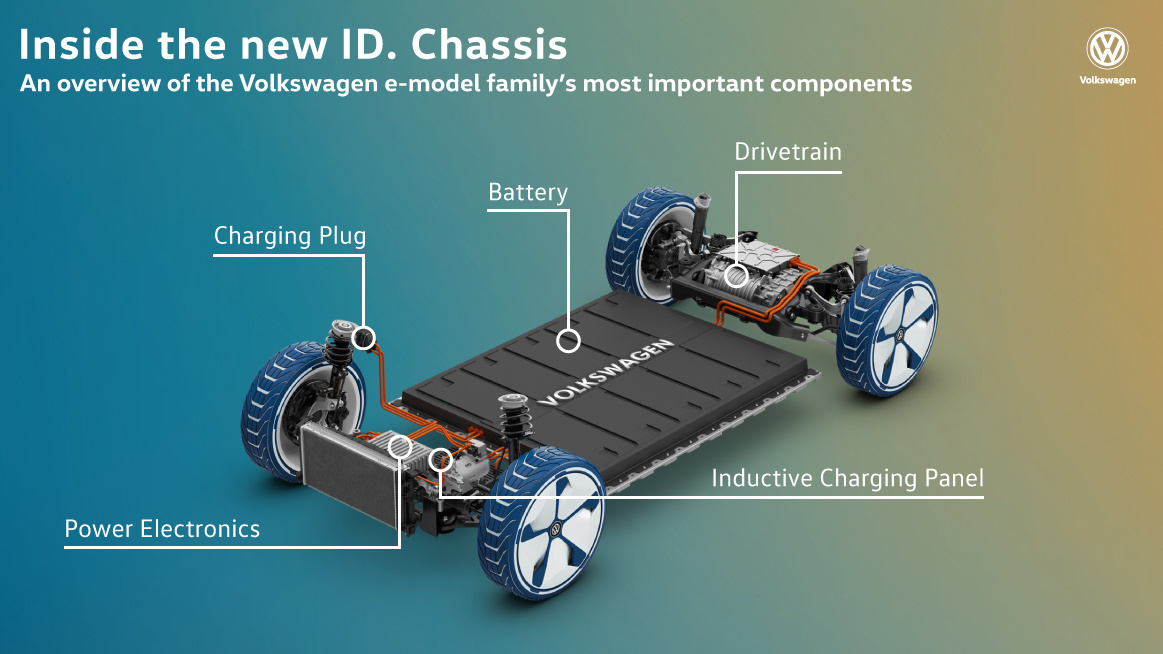

The centerpiece of the MEB is the rolling chassis without the bodywork and interior, shown exactly as it will be used in production cars. VW says the MEB enables “a hitherto unachievable price-service ratio” and will be the key to its “electric car for all.” Brand board member for e-mobility Thomas Ulbrich describes it as a technological milestone, “similar to the transition from the Beetle to the Golf.”

That’s not an overstatement, given that some 10 million vehicles across the VW Group will be based on this platform in the first wave alone. By the end of 2022, four of the automaker’s brands will sell 27 MEB-based models worldwide, ranging from compact cars to the Bulli.

“The MEB is the economic and technological backbone of the electric car for all,” says Ulbrich. MEB is said to bring many benefits to customers, including the possibility to install larger batteries for an increased driving range. Furthermore, placing the flat battery in the floorpan has a double advantage: good road-holding and “generous” space inside the cabin.

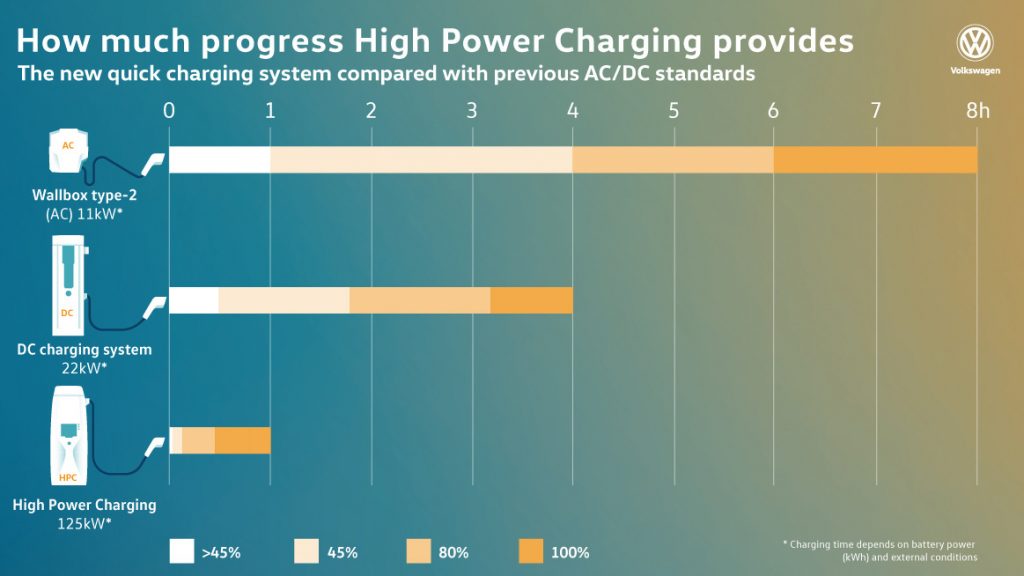

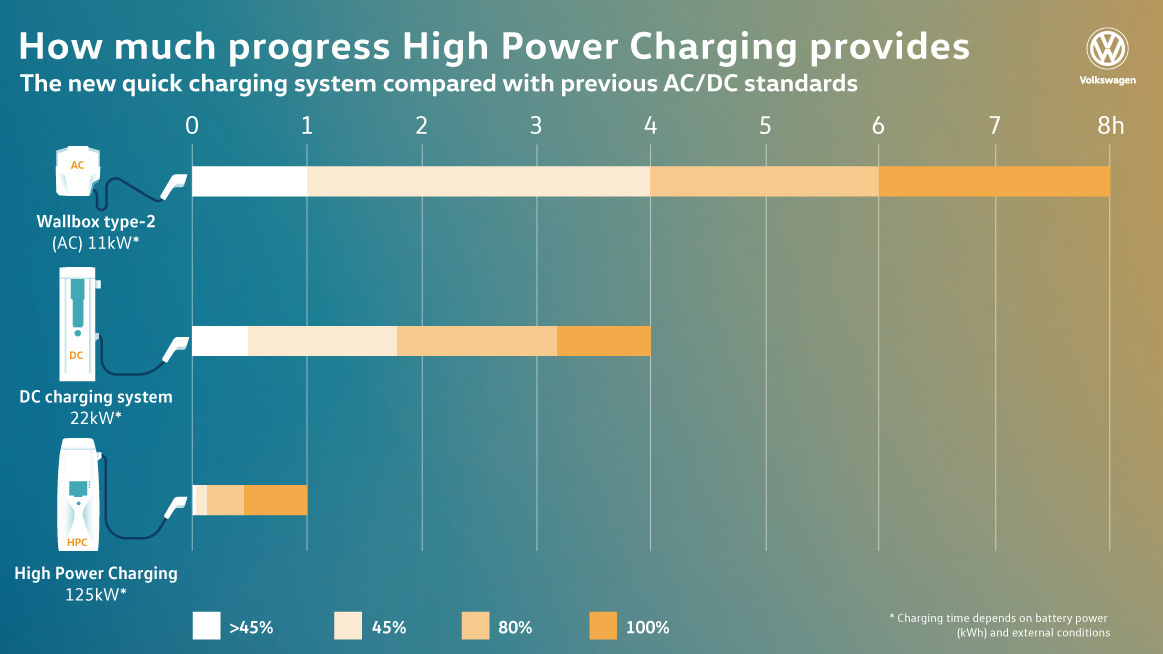

All members of the ID family are designed for fast charging. The battery can be charged to 80 percent of capacity in about 30 minutes using a fast charger. That’s thanks to a completely new, significantly more powerful battery system developed by Volkswagen Group Components.

All Volkswagen ID models will be made in Germany, with the company investing €1.2 billion of a total €6 billion budgeted for e-mobility at the Zwickau plant where the production models of the ID family will be made. Zwickau will become the first MEB plant and the largest competence center for e-mobility in Europe.

A further €1.3 billion will be invested in the Braunschweig, Salzgitter, and Kassel plants. The battery system will be made at the Braunschweig facility, which already builds the batteries for the e-up!, the e-Golf and the Passat GTE plug-in hybrid. The plant is being expanded to be able to build up to 500,000 battery systems per year.

VW will produce rotors and stators for the MEB at the Salzgitter plant, while the Kassel facility will be responsible for the electric motors.

Finally, besides the MEB, the German company is also showing a design prototype of the Volks-Wallbox, which is described as “an affordable home system that makes charging the ID family easy and convenient”.