Ford will use graphene to reduce noise, lower weight, and improve heat conductivity in its vehicles.

Graphene is considered a bit of a wonder material, and while it hasn’t hit the mainstream market (yet), it does enjoy some limited use in select industries. It is 200 times stronger than steel and one of the most conductive materials in the world.

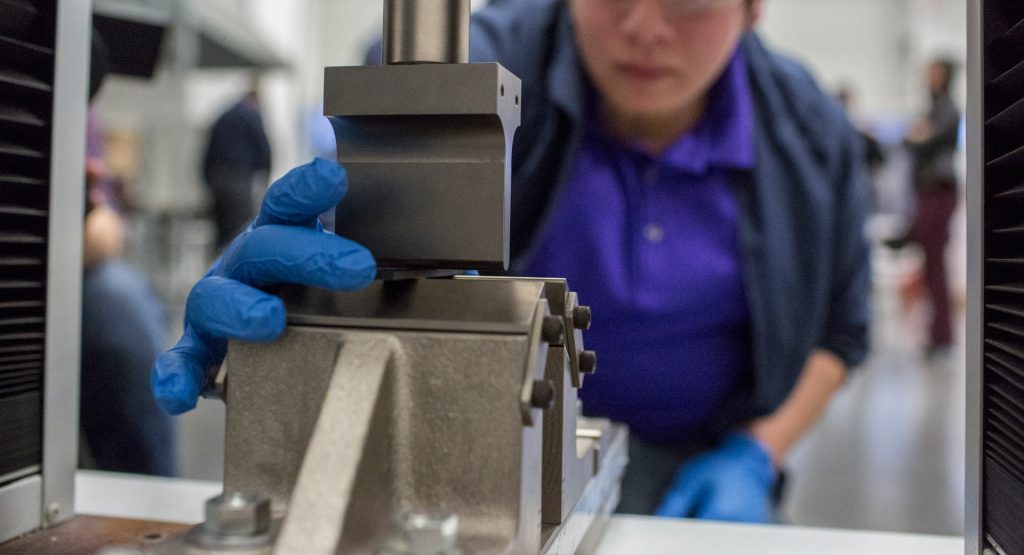

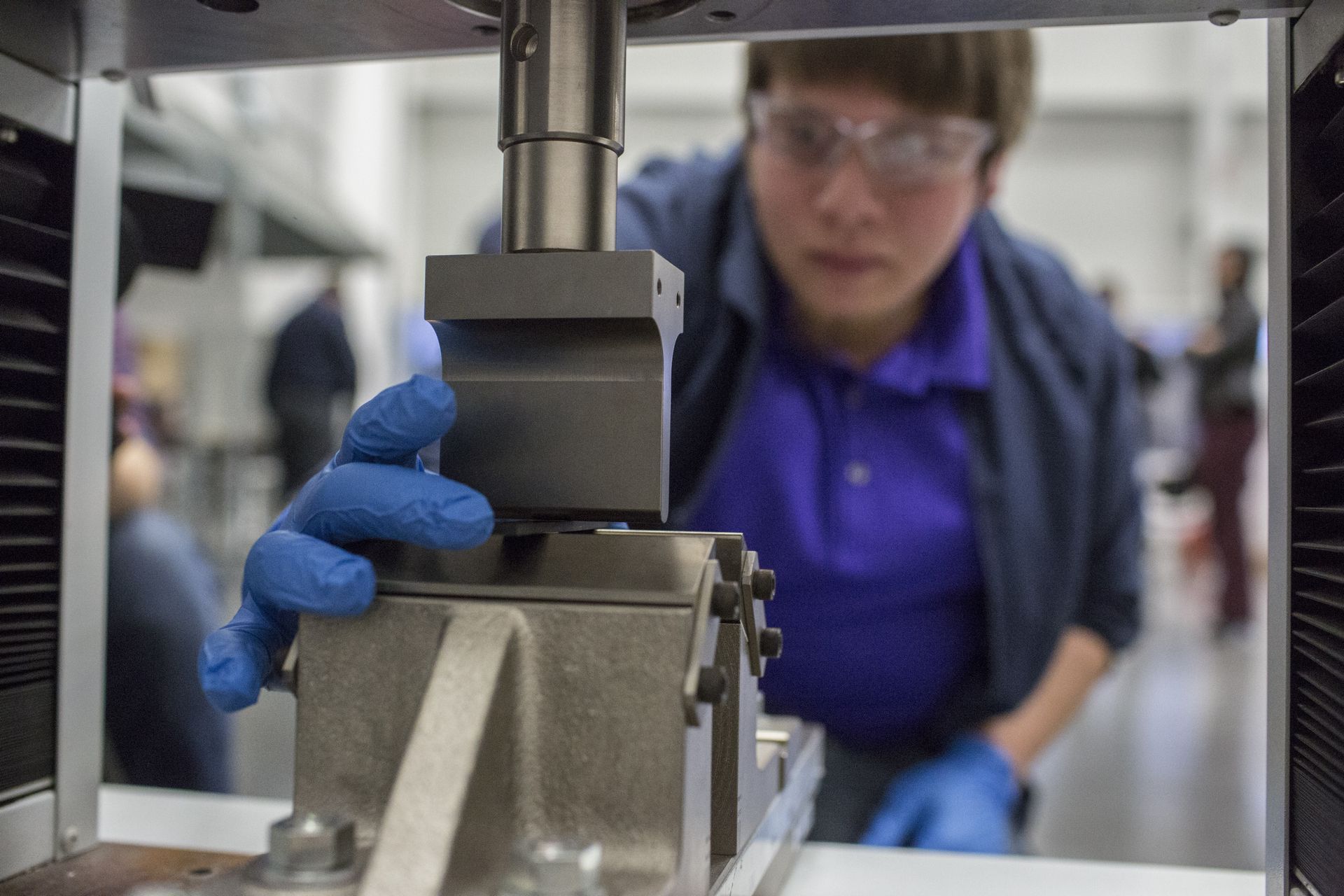

By collaborating with Eagle Industries and XG Sciences, Ford has been able to incorporate graphene in fuel rail covers, pump covers and front engine covers. Ford mixes the graphene with foam constituents and says that it results in a 17 per cent reduction in noise, a 20 per cent improvement in mechanical properties, and a 30 per cent improvement in heat endurance properties compared to foam that doesn’t incorporate graphene.

“We are excited about the performance benefits our products are able to provide to Ford and Eagle Industries,” XG Sciences chief executive Philip Rose said.

“Working with early adopters such as Ford Motor Company demonstrates the potential for graphene in multiple applications, and we look forward to extending our collaboration into other materials, and enabling further performance improvements.”

Ford began studying how to use graphene for various automotive applications in 2014. Unlike most solutions to reduce unwanted noise, graphene doesn’t add weight but actually reduces it.

The car manufacturer will introduce graphene elements on the Ford F-150 and Mustang by the end of the year. The material will then be introduced throughout Ford’s range.

Graphene was first isolated using a piece of tape to pull off layers of graphite from a pencil lead, creating a material that is just a single layer thick.