Audi has announced it has found a way to put partially matting into volume production.

That will allow Audi to build further individualized cars in the future, and the first model to benefit from the new painting process is the Q2 crossover. The company will use the new process for the first time in volume production with the #2 special edition of the Audi Q2. The top layer of paint is subjected to a fine beam that minimally roughens it, creating a matte image.

As a result, the painted sheet metal can display lettering, logos or even photos “with pixel accuracy and abrasion resistance.”

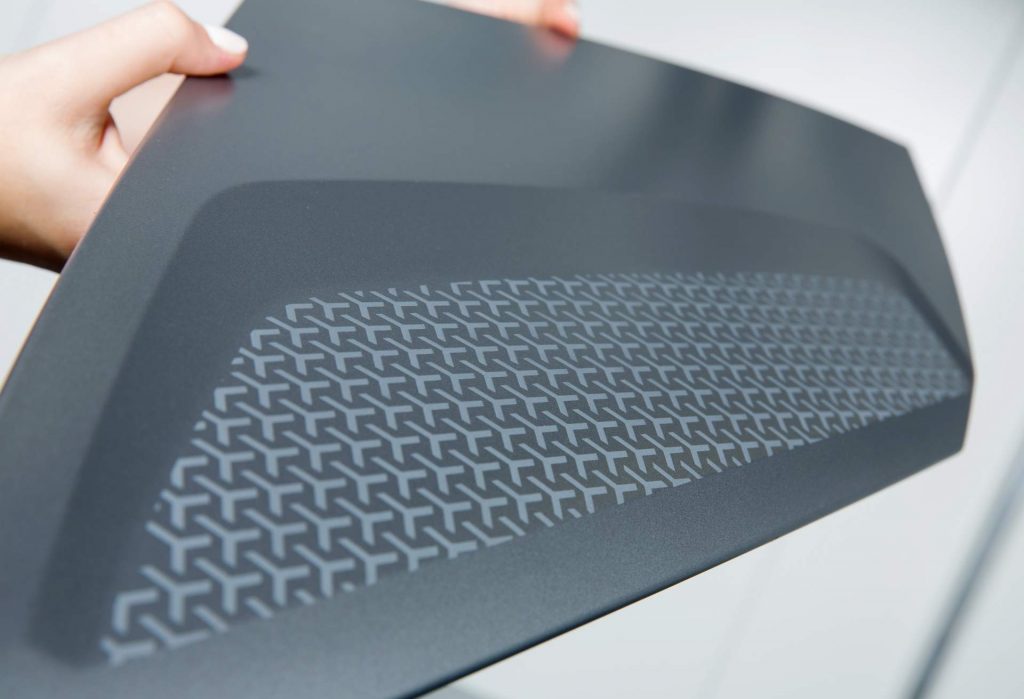

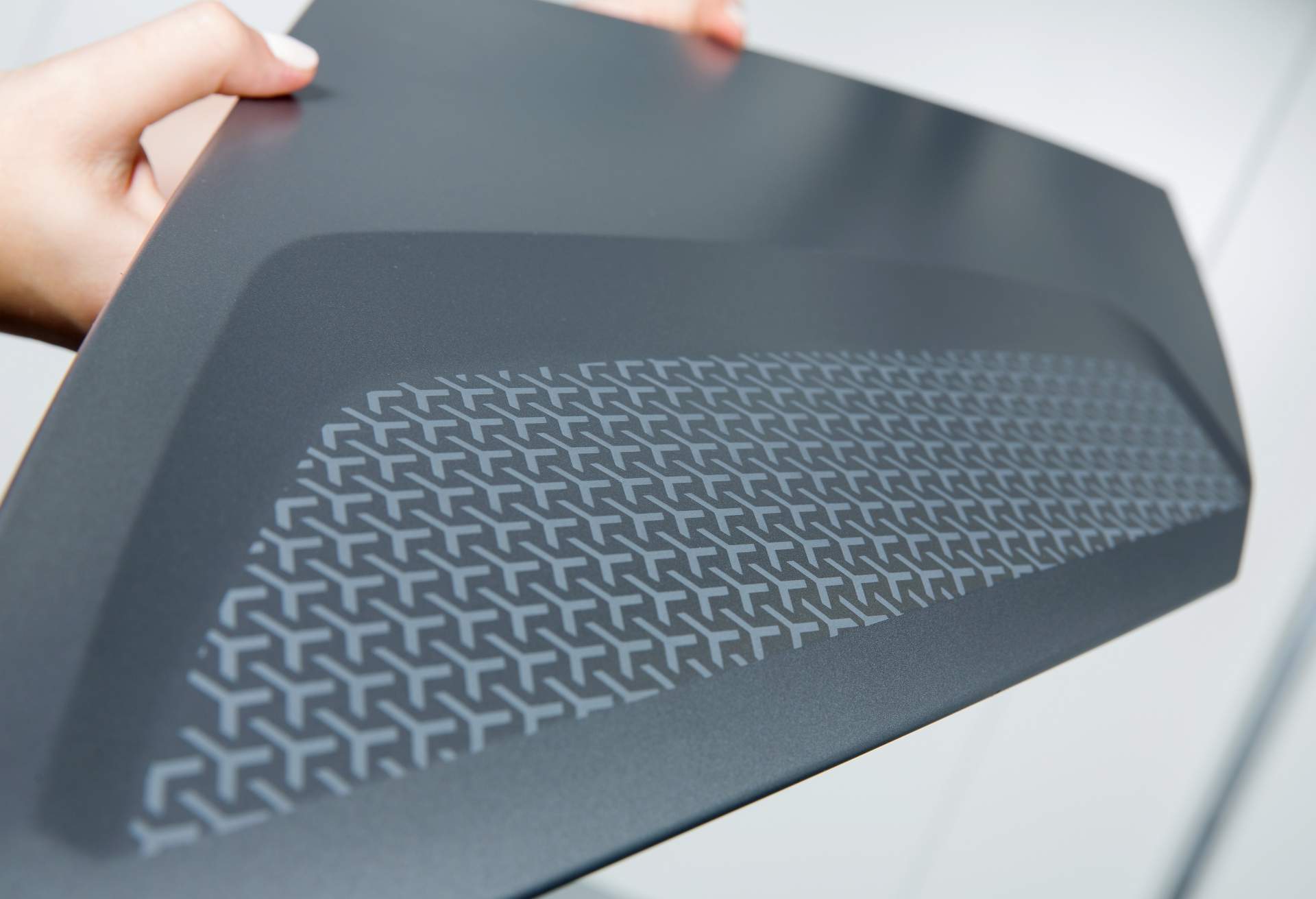

The partial matting process was developed by a team in the Technology Development division at Audi’s Ingolstadt plant. Here’s how it works. The first step consists of an employee sticking a template made of thin plastic film onto the painted component. In the case of the Audi Q2, that’s the side blade.

After that, a specially developed system sprays the component under vacuum with a fine powder of crushed glass. What that does is remove a few thousandths of a millimeter from the top layer of clear lacquer. At the same time, the spraying roughens the lacquer slightly.

Thanks to the difference in surface structure, the motif stands out clearly after the template is removed. The Audi Q2 #2 special edition, available in Germany since mid-October, features a large pattern of crosses painted using the new process. It only takes a minute to matte a sideblade for the Audi Q2.

According to Audi, the partial matting gives it an advantage over its competitors as it allows it to personalize each painted surface in the interior or exterior of the car. The very first cars to feature partial matting were the 24 examples of the Audi R8 Coupe V10 plus “selection 24h” special edition.

Released in 2016, they featured “R8” lettering on the sideblades. However, at the time the partial matting was mostly done by hand.