Ford has announced that the upcoming Mustang GT500 will utilize 3D printed parts.

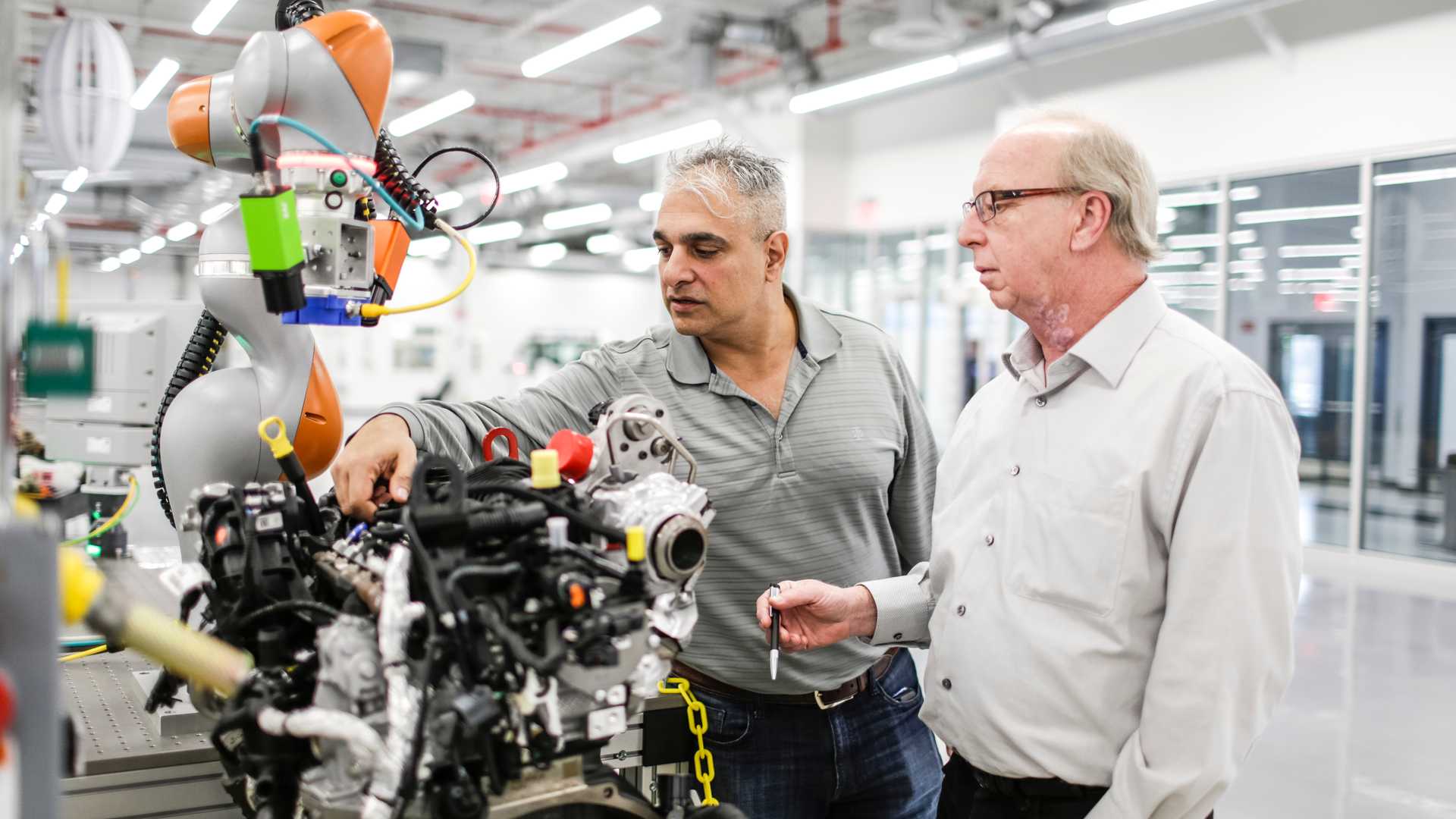

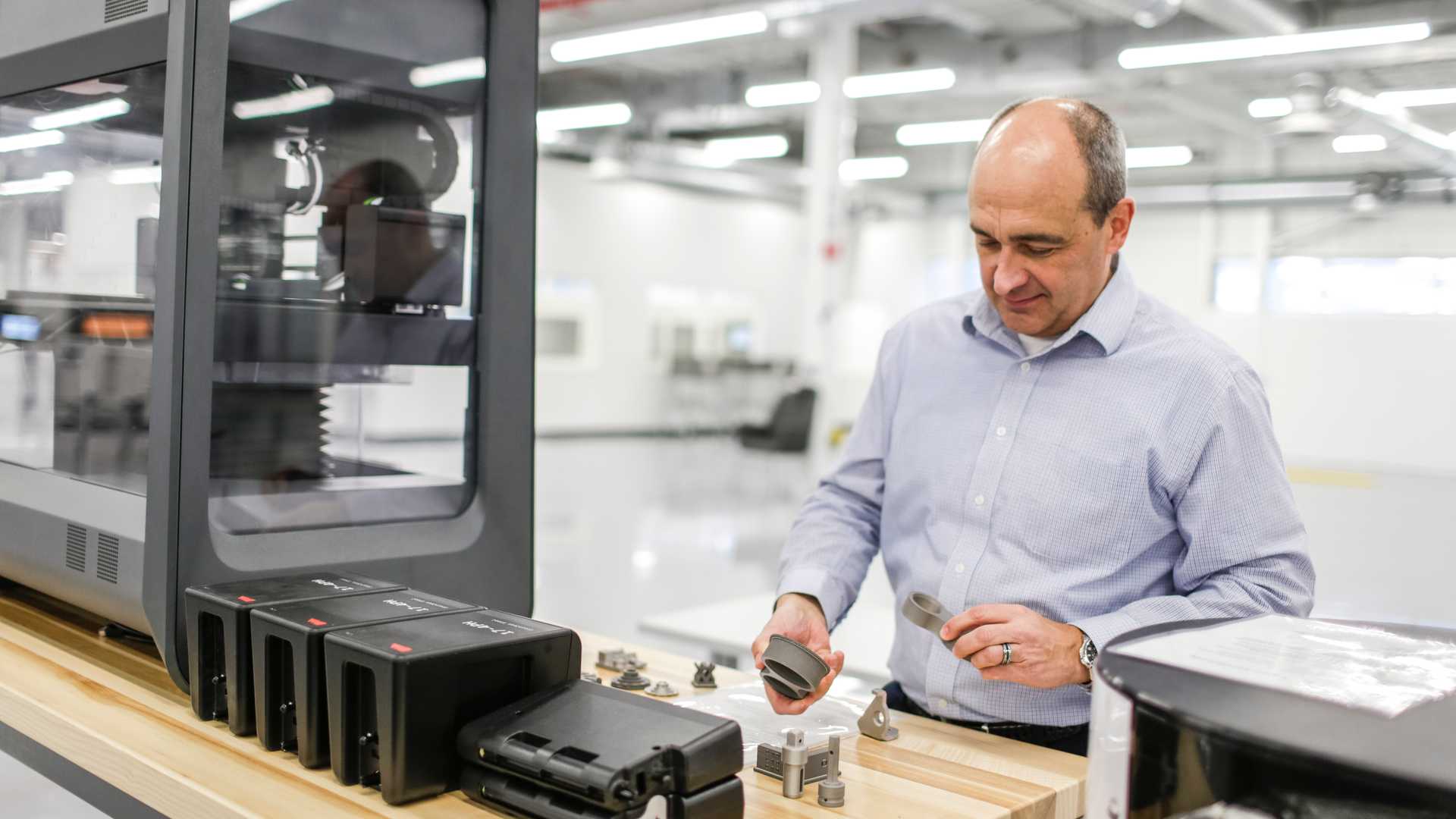

Earlier this week, the American car manufacturer celebrated the opening of its new Advanced Manufacturing Center in Redford. The $45 million facility in Redford, Michigan, is home to no less than 23 3D printing machines, works with 10 3D printing companies, and churns out components for a number of Ford vehicles.

Among the first parts to be 3D printed by Ford will be two individual brake parts for the high-performance Mustang GT500. While Ford hasn’t announced exactly what these parts will be, nor what they will be made from, they will likely be cheaper to produce and lighter than similar parts constructed using more traditional methods.

The Mustang GT500 isn’t alone in its use of 3D parts. Ford F-150 Raptor models built for China include a 3D printed interior part and the carmaker claims these tools remove weeks from the Ranger’s production timeline.

While it’s interesting to know that the upcoming Mustang GT500 will use this emerging technology, we have far more interesting details about the car.

First and foremost, the vehicle will use a supercharged, flat-plane crank V8 pumping out in excess of 700 hp, making the GT500 Ford’s most powerful production vehicle, beating even the 647 hp GT supercar. A bespoke design will also ensure the GT500 stands out from all other Mustang variants. Leaked images from earlier this year showed off elements like a large rear wing, carbon fiber wheels, enlarged air intakes, and a bulging hood.

The new Ford Mustang GT500 will celebrate its global premiere on January 14 at the Detroit Auto Show and will hit the market later in 2019.