If the engine is the heart of a car, then the new Nissan Altima has some blue blood running through its veins. It comes courtesy of a special manufacturing technique that has found its way into the 2.5-liter, four-cylinder engine that powers the midsize sedan.

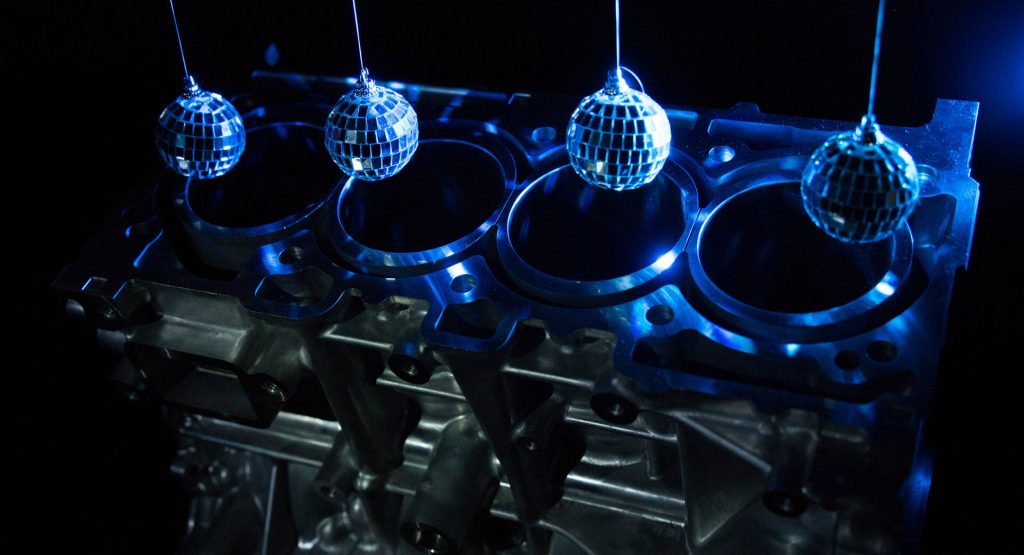

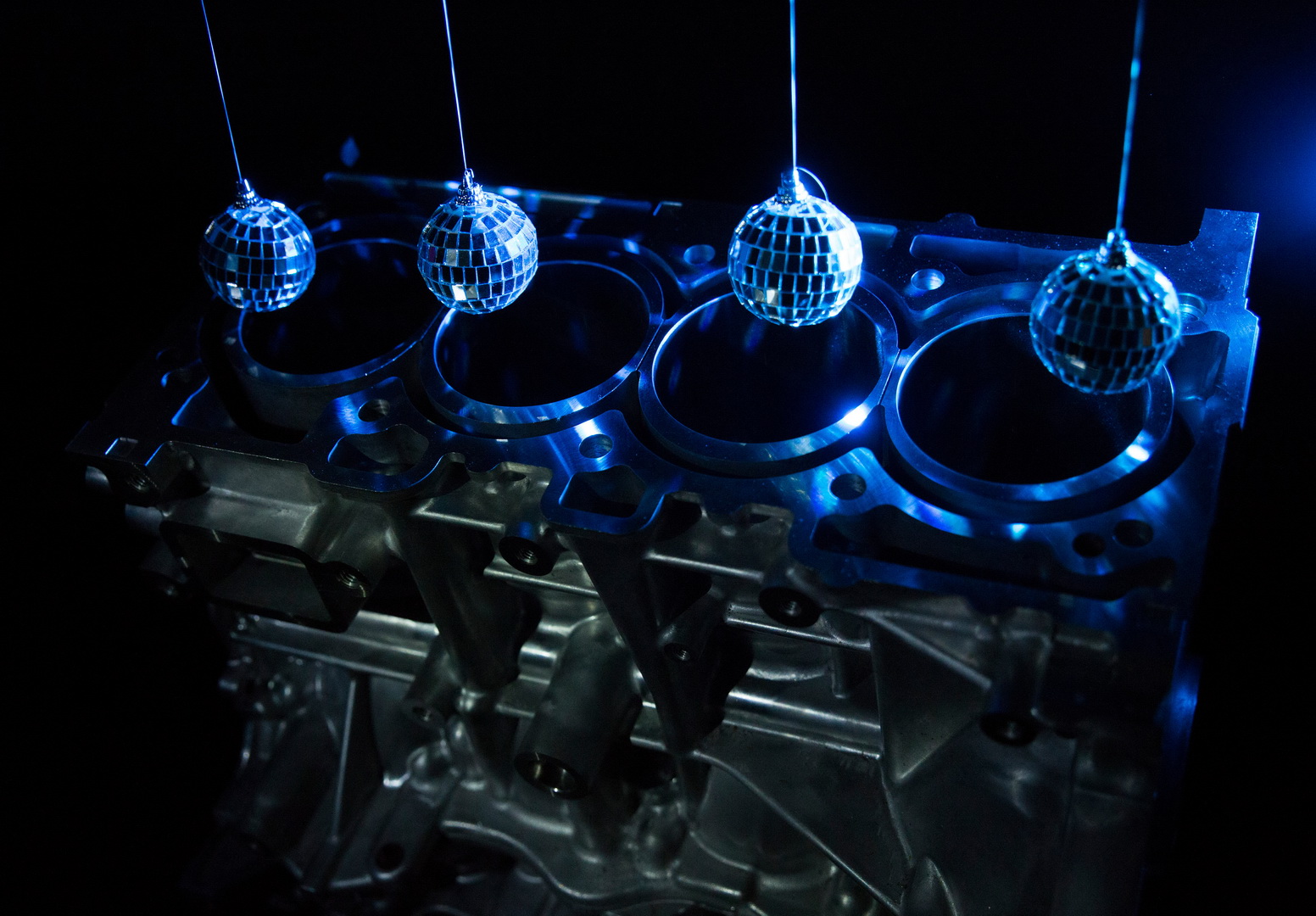

First used in the GT-R and then applied to other models such as the Sentra Nismo, this so-called mirror bore process is found inside the cylinders of the engine block.

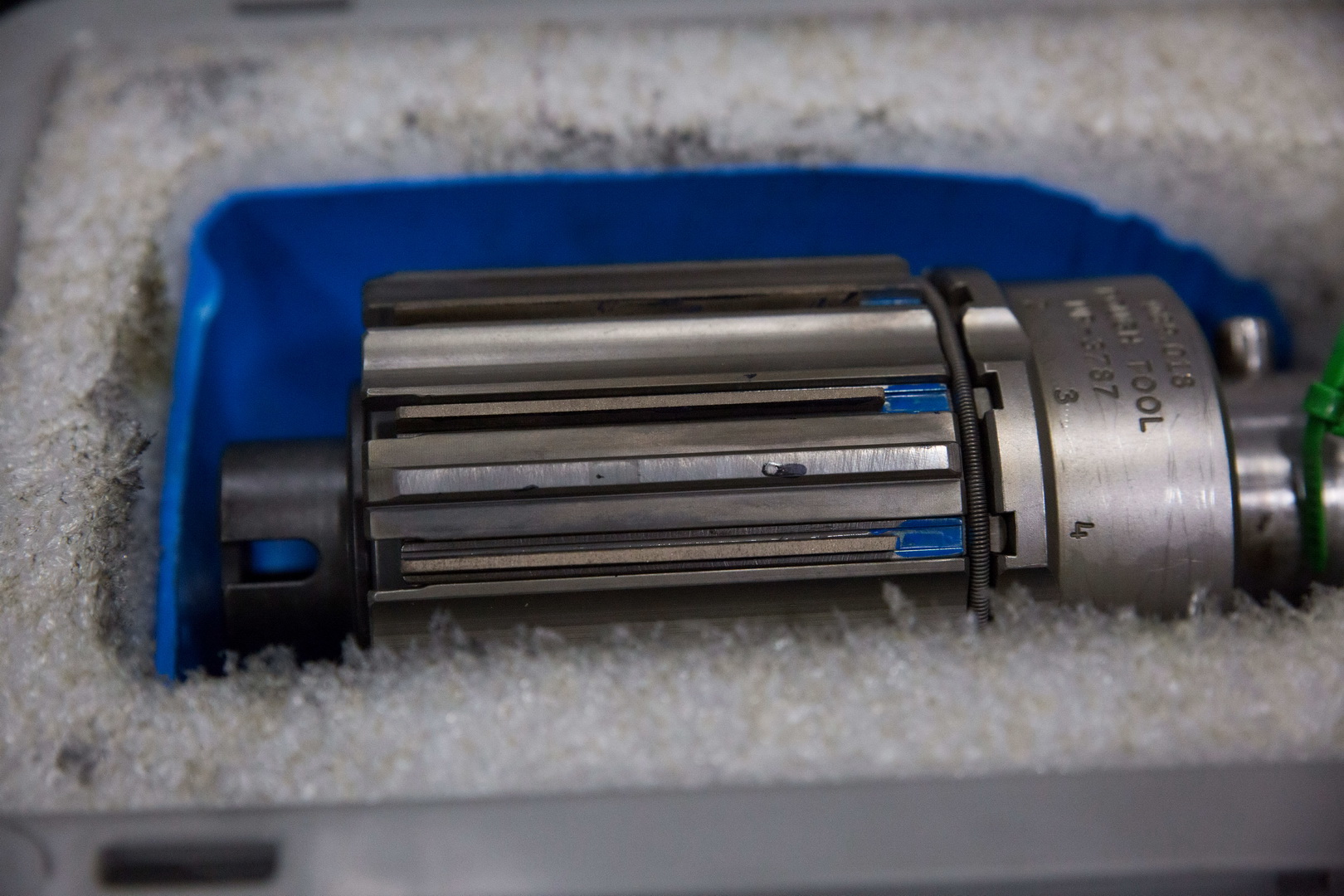

The technique involves spraying and polishing the cylindrical space inside the engine in which the pistons move. The coating has a 200-micron thickness, or twice as thick as a human hair. Then, a special tool is used to polish the cylinder bore, giving the process its name. The whole idea behind this technique is to improve efficiency and reduce friction.

Also Watch: 2019 Nissan Altima Is A Vast Improvement Over Its Predecessor

“Advanced technology like the mirror bore process only makes sense for Nissan if we can offer it to as many customers as possible”, said North America engineering director at Decherd plant, Jay Boyte. “The end result is an innovative and efficient engine made with manufacturing technology usually not available at this volume or price point.”

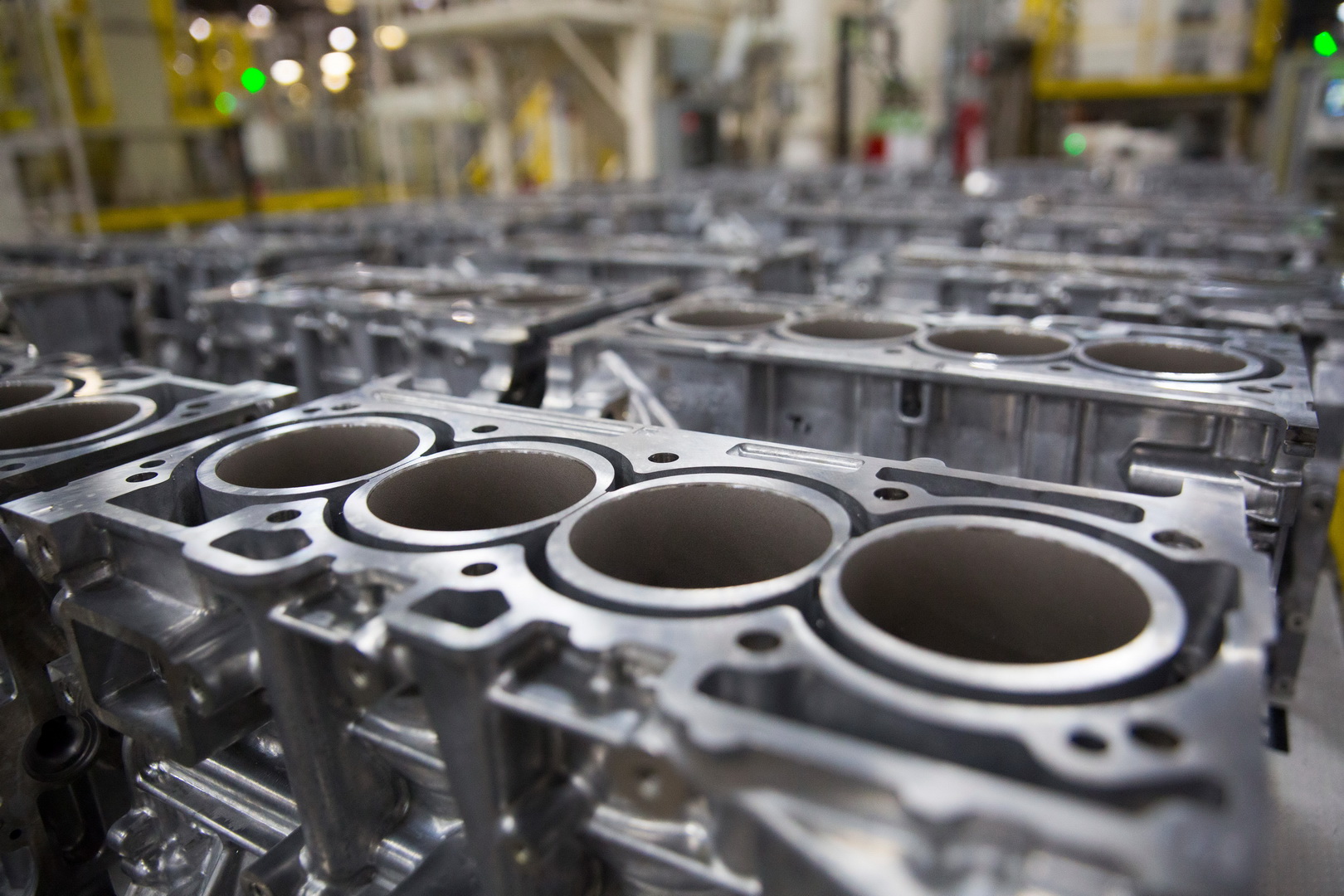

The 2.5-liter four-pot that powers the new Altima pushes out 188 hp (191 PS / 140 kW) and 180 lb-ft (244 Nm) of torque. It’s assembled at Decherd, Tennessee, which employs 1,700 people. The facility puts together about 1.4 million engines annually, or one every 19 seconds.

Since the Decherd plant was inaugurated in 1997, nearly 13 million engines have been assembled there. The facility makes the mills that go in the Altima, Frontier, Maxima, Pathfinder, Rogue and Titan, as well as those in the Infiniti QX60 and the electric motors for the Leaf.

https://www.youtube.com/watch?v=x4Vcbm4yeSA