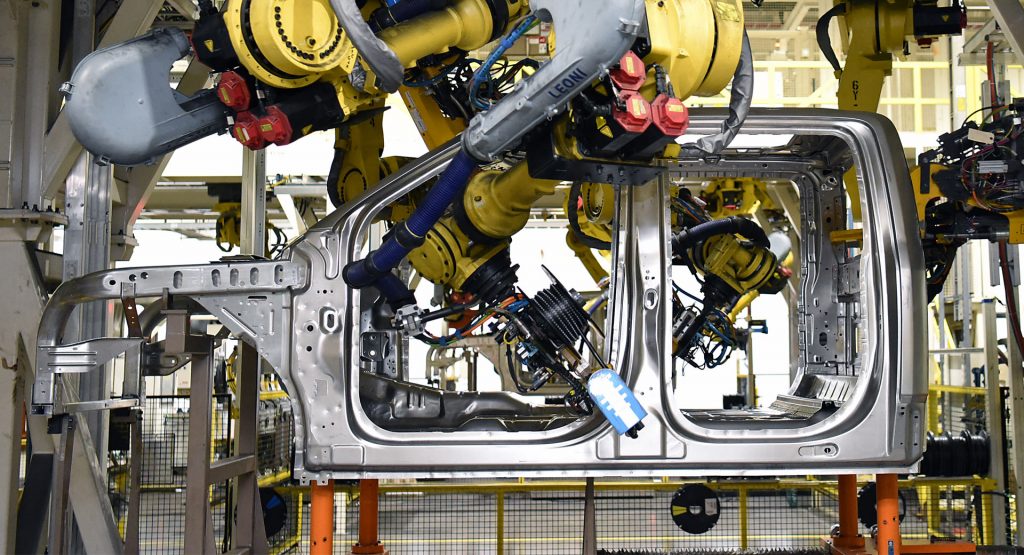

Aluminum and carbon fiber used to limited to high-end automobiles, but the materials have now trickled down to trucks such as the Ford F-150 and GMC Sierra.

Bloomberg notes the shift to aluminum and carbon fiber has been driven by increasing fuel economy standards and the desire to make vehicles lighter. This has driven down demand for steel in the automotive sector and the publication spoke to analyst Akihito Fujita who believes steel will only account for 62% of the weight of an average new vehicle in 2025 – down from 70% in 2015.

This is bad news for steelmakers as some are heavily reliant on the automotive industry. As a result, they’re fighting back with lighter steels and new construction techniques.

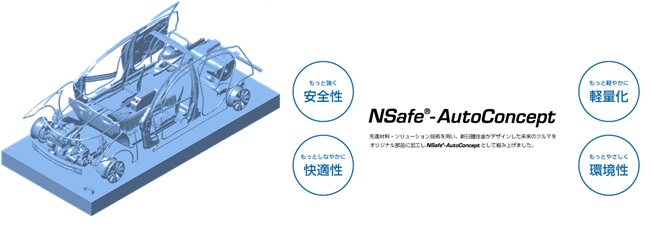

In particular, Bloomberg highlighted Nippon Steel which showed its NSafe Auto concept earlier this year. Billed as a “next-generation automotive structural concept,” the structure used six different grades of steel. Some of the steel was significantly stronger than what is typically used in automobiles, but this allowed Nippon to save weight in other areas. Thanks to this approach, the concept was approximately 30% lighter than a traditional steel vehicle and this put it on par with an aluminum bodied model.

There’s no word on if the NSafe approach would be cheaper than going with aluminum or carbon fiber, but Nippon Steel is also experimenting with other ways to make steel lighter. One involves mixing steel with “small amounts of plastics,” but it’s just an experiment at this point.

It remains unclear if the new materials and techniques will eventually find their way into future automobiles, but it’s possible as automakers continue to look for ways to cut costs and lighten their vehicles.