Production of the all-electric Porsche Taycan kicked off last month at the company’s Zuffenhausen, Germany production facility. This 30-minute long video details many of the processes the car goes through to come to life.

Like so many other cars on the market, the Porsche Taycan is built primarily by advanced robots. In this clip, these robots can be seen performing complex tasks including welding and fitting various body panels including the doors. Highly-trained employees then check over the shells and smooth everything out before the cars are dipped in primer and sent to the paint booth.

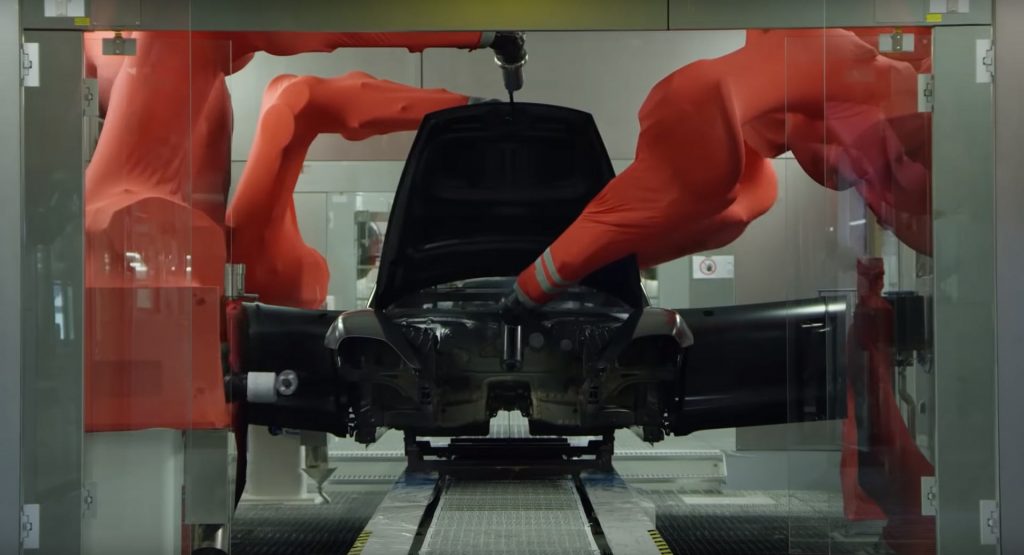

Highly advanced robotic arms are tasked with painting each and every Taycan and watching them operate is quite remarkable. They are precise and quickly paint the exterior of each Taycan much faster than a human could. The paintwork is then finely checked-over by production workers.

Also Watch: Is The Taycan A True Porsche? Yes, Indeed – And Then Some

The second half of the video focuses on the Taycan’s powertrain where humans play an important role in assembly the electric motors. Each motor is tested and before long, the electric powertrain is mounted into the car’s shell. When everything is put together, each Taycan is strapped onto a rolling road to ensure everything is operating perfectly. Each car is then given a final once over before being sent on its way.

Porsche unveiled the long-awaited Taycan at the Frankfurt Motor Show in Turbo and Turbo S forms. The first deliveries are expected to be made this coming December.