Volkswagen has kicked off production of the ID.3 at Zwickau in Germany. A team of highly-trained employees is putting together the electric hatchback, using components such as the electric motors, battery systems and other parts made in Brunswick, Kassel, Salzgitter and Wolfsburg.

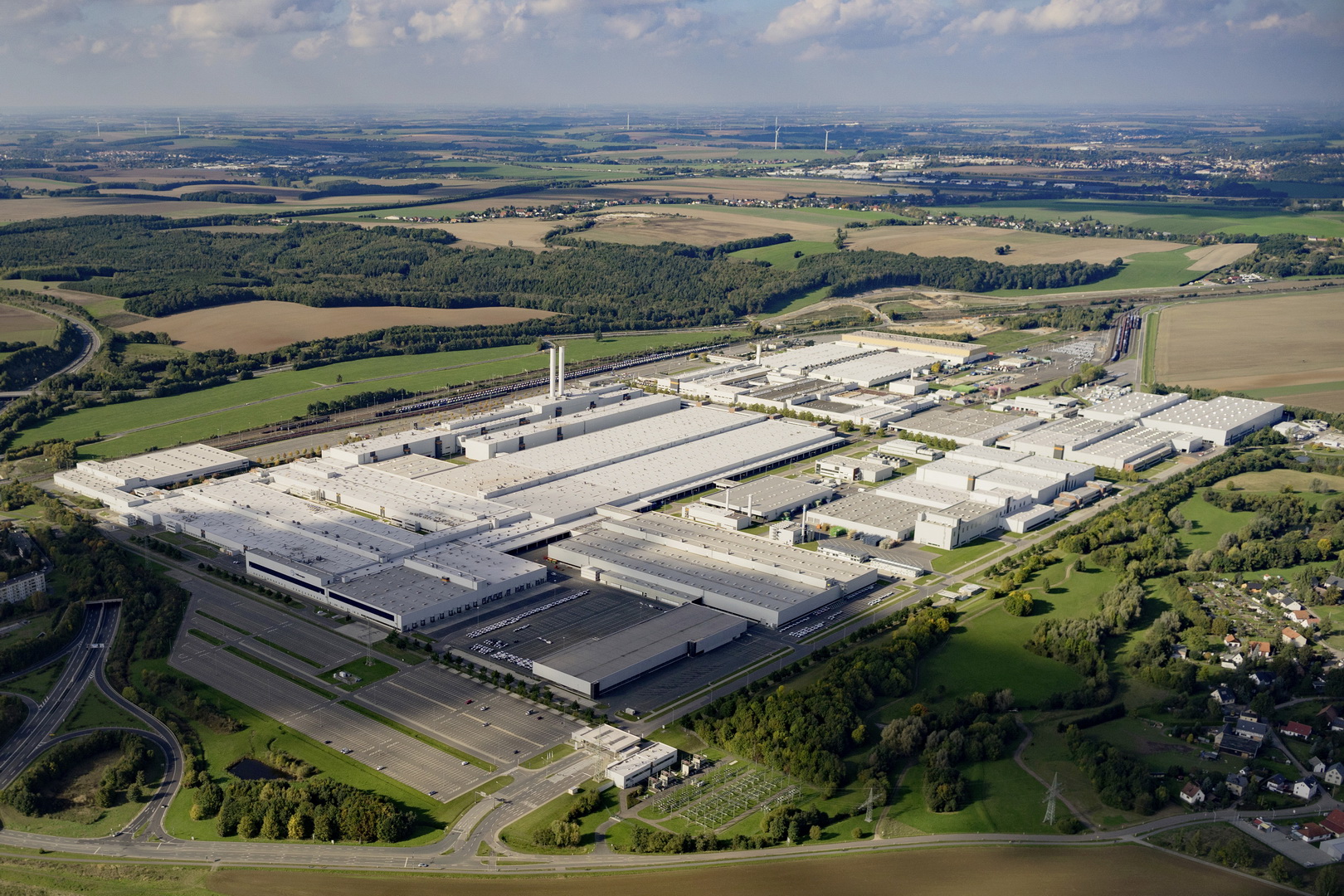

The Zwickau factory will be making approximately 100,000 zero-emission cars next year, and from 2021, up to 330,000 EVs will leave the assembly lines, counting six vehicles built on the MEB platform from three VW Group brands. When the final expansion stage ends in a couple of years, the facility will have seen investments totaling €1.2 billion ($1.34 billion).

Video: Here’s a Close Look At The ID.3, Volkswagen’s Most Important New Car In Many Decades

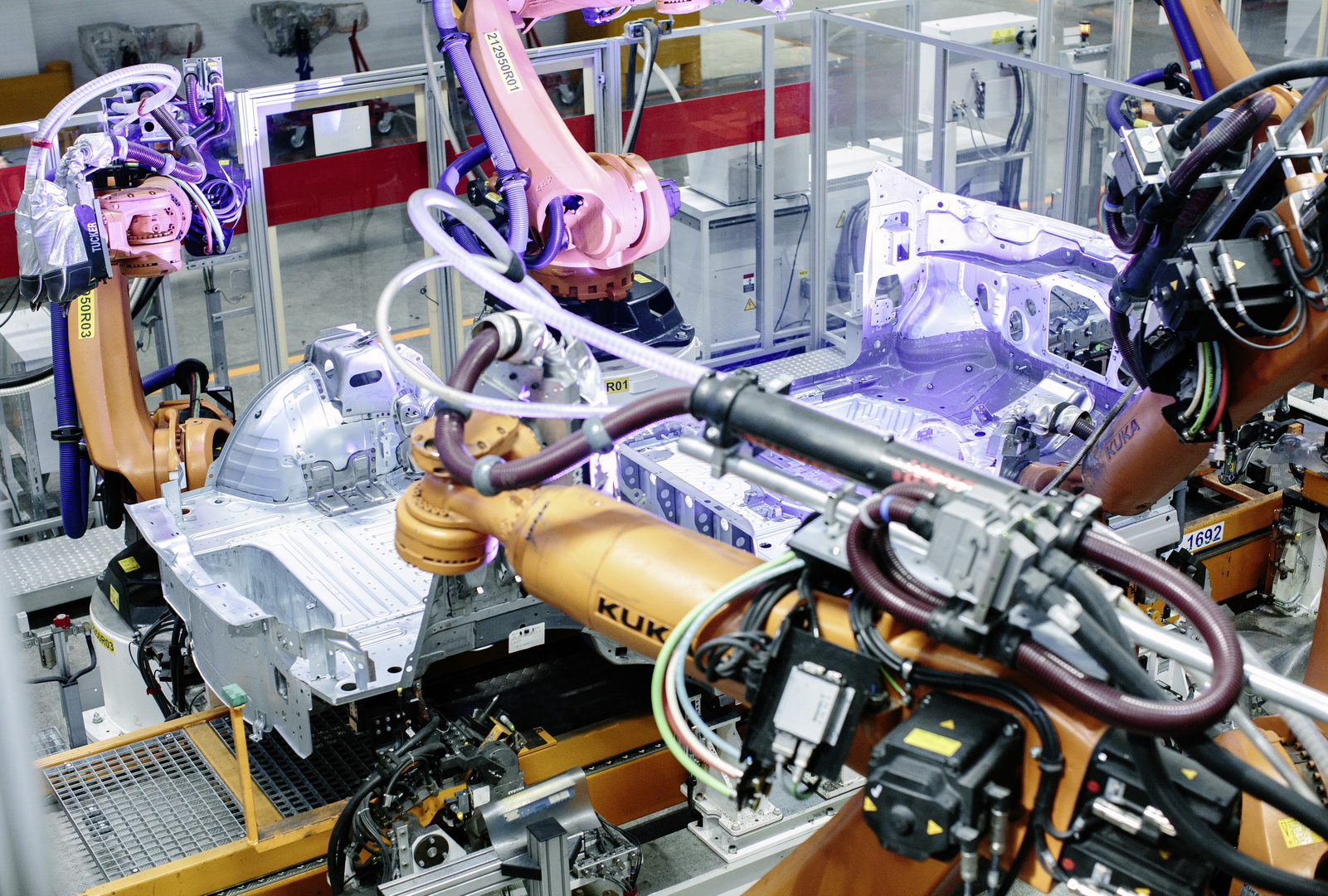

“The ID.3 is a high-tech car from a high-tech factory. With some 1,700 robots, driverless transport systems and fully-automated manufacturing processes, Zwickau gives a contemporary insight into the shape of forward-looking high-volume production of EVs”, said VW Brand Board Member for E-Mobility, Thomas Ulbrich. “Ultimately, though, it is the people who build the cars who are the key to our success: our team in Saxony mastered the two-year conversion phase, culminating in today’s SOP with much know-how and dedication. An outstanding team achievement!”

Volkswagen will launch the ID.3 in markets throughout Europe next summer, with prices starting at under €30,000 ($33,490) in Germany. So far, more than 35,000 customers in international markets have already expressed their interests in purchasing one, paying a refundable deposit.

The base 45 kWh battery gives the VW ID.3 a 330 km (205 miles) range, the mid-spec 58 kWh model offers 420 km (261 miles) and finally the top-of-the-line 77 kWh variant is capable of travelling for 550 km (342 miles) on a full charge.