Ford is teaming up with McDonald’s USA in order to convert coffee bean skin into various vehicle parts.

According to the two companies, millions of pounds of coffee chaff (the dried skin of the bean) are dumped every year. Now, there’s something to be done about that, as the chaff can apparently be converted into a durable material using high temperatures and low oxygen levels – plus a mix of plastic and other additives.

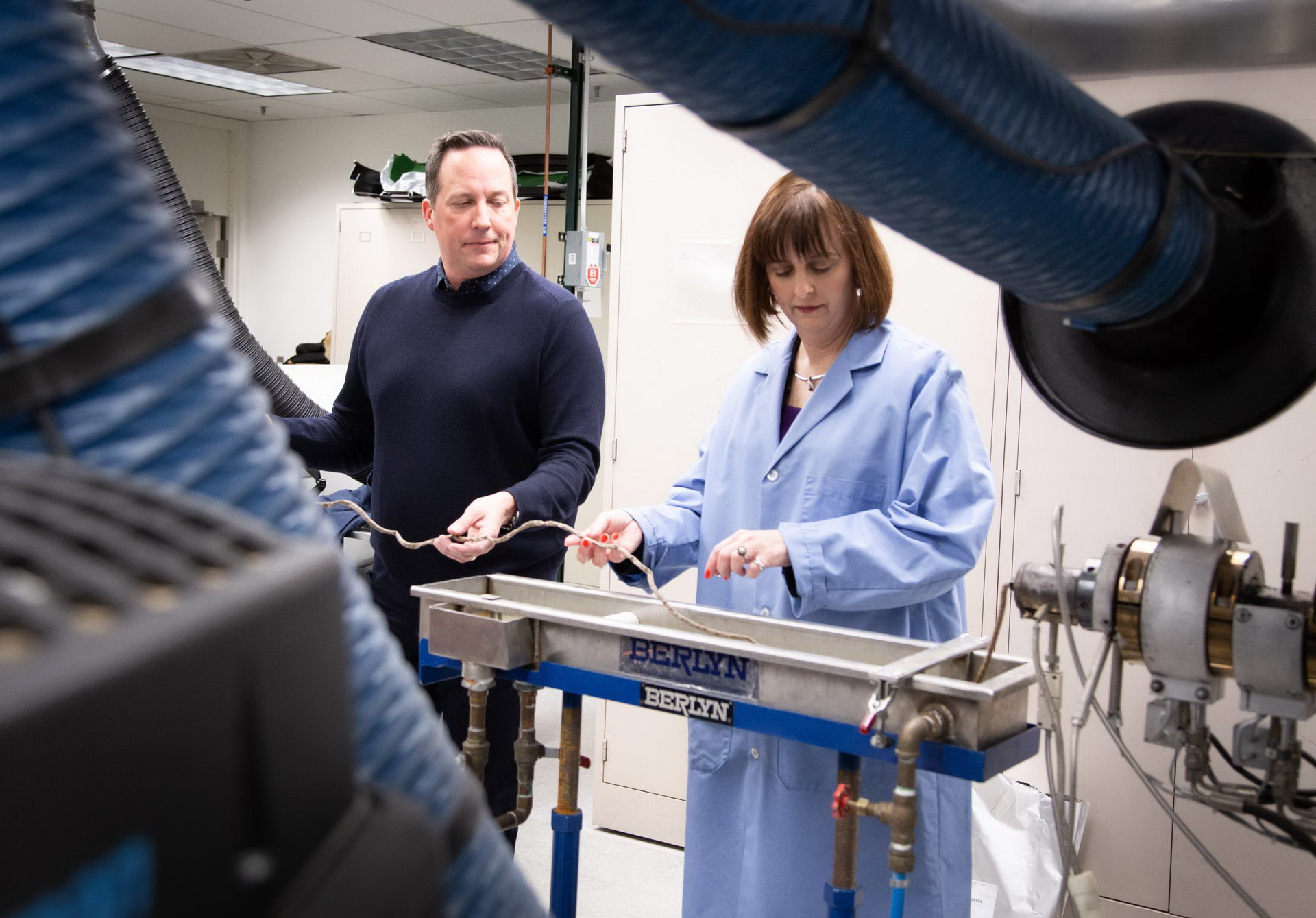

In the end, you’re left with pellets, which can then be formed into different shapes such as headlight housings and other interior and under-hood components that actually meet quality specifications.

Also read: I’m Not Lovin’ It – McDonald’s Drive-Thru Incident Leads To Car Bombing

The resulting components are said to be roughly 20% lighter and require up to 25% less energy during the molding process. Ford also says that the heat properties of the chaff are better than what they currently use.

“McDonald’s commitment to innovation was impressive to us and matched our own forward-thinking vision and action for sustainability,” said Ford senior tech leader and researcher, Debbie Mielewski. “This has been a priority for Ford for over 20 years, and this is an example of jump starting the closed-loop economy, where different industries work together and exchange materials that otherwise would be side or waste products.”

With that in mind, the fast food giant will now direct a significant portion of its coffee chaff in North America to Ford so that it can be used for vehicle parts.

“Like McDonald’s, Ford is committed to minimizing waste and we’re always looking for innovative ways to further that goal,” said McDonald’s senior exec, Ian Olson. “By finding a way to use coffee chaff as a resource, we are elevating how companies together can increase participation in the closed-loop economy.”

This process also involves two other companies in Varroc Lighting Systems and Competitive Green Technologies. The former supplies the headlights while the latter is the processor of the coffee chaff.