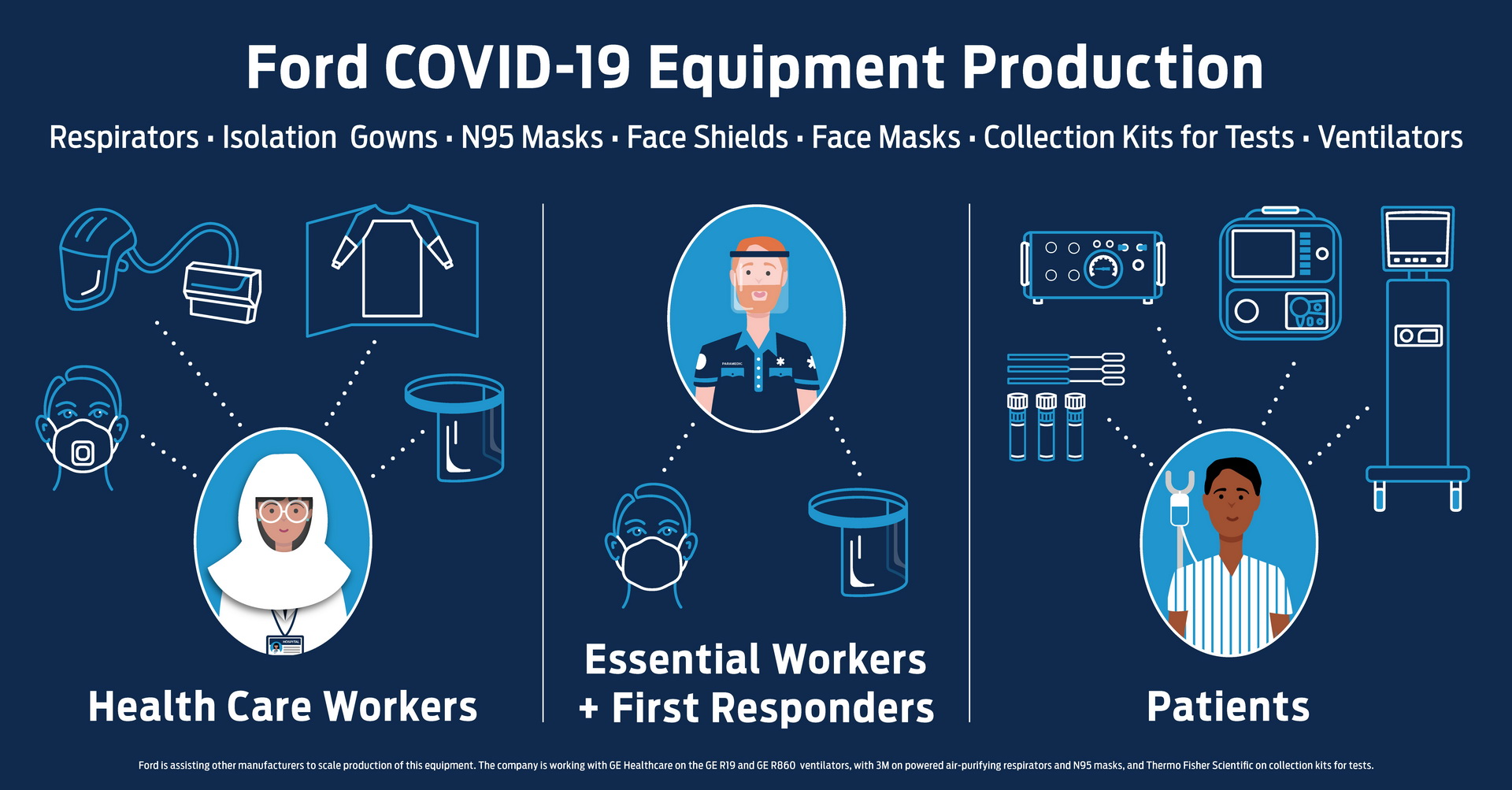

Ford is expanding its efforts in designing and producing medical equipment and supplies for healthcare workers, first responders and patients struggling to fight off the novel coronavirus.

The U.S. carmaker is producing face shields and a new powered air-purifying respirator, and is now scaling production on reusable gowns made from airbag materials, as well as face masks. Lastly, Ford is also helping expand production of COVID-19 collection kits.

“We are doing all we can to expand production and availability of personal protective equipment to help keep the true heroes – medical personnel – and our communities safe in the fight against COVID-19,” said Adrian Price, director, Global Core Engineering for Vehicle Manufacturing.

Read Also: Ford And FCA Join The Fight Against Coronavirus, Making Masks, Ventilators And Face Shields

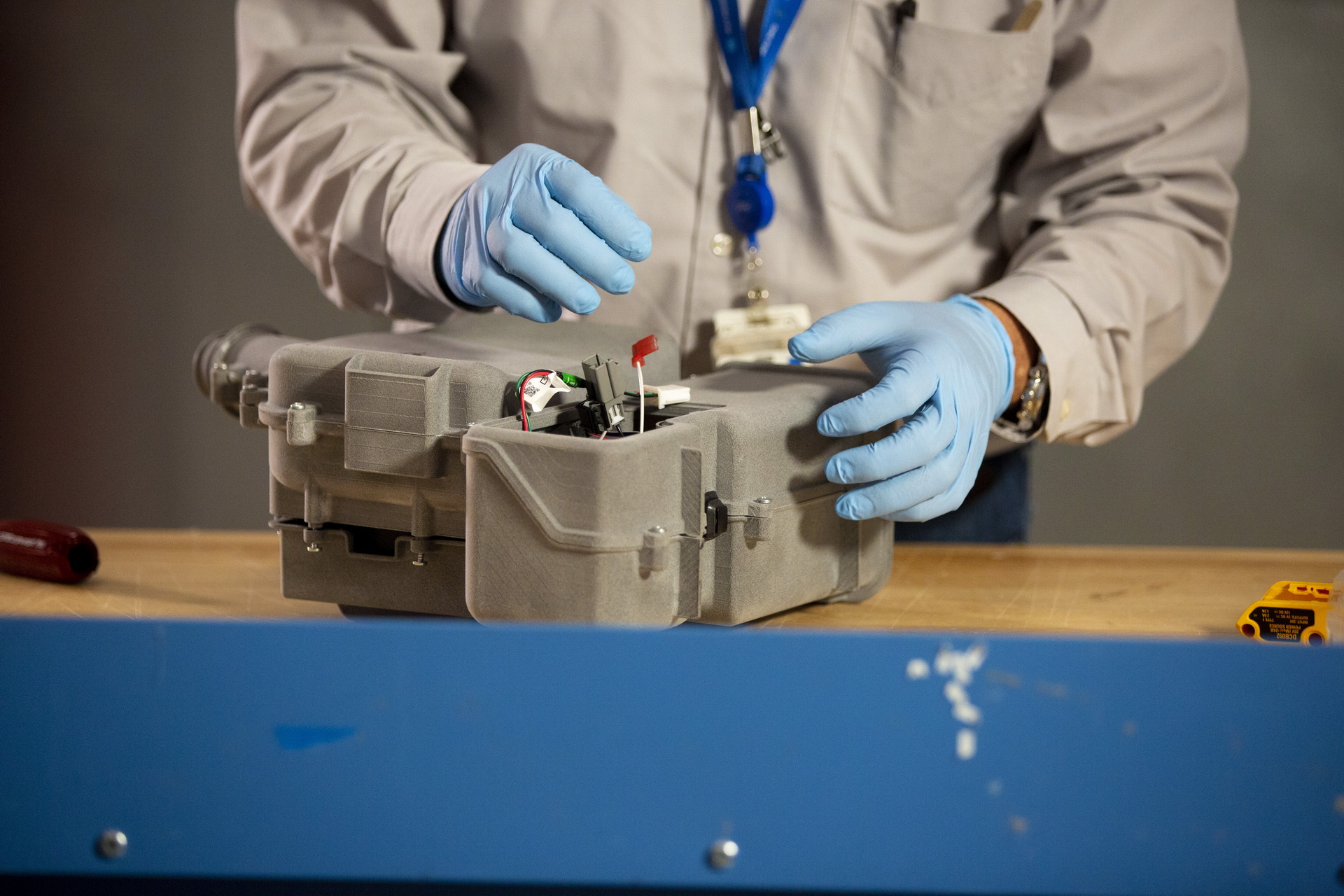

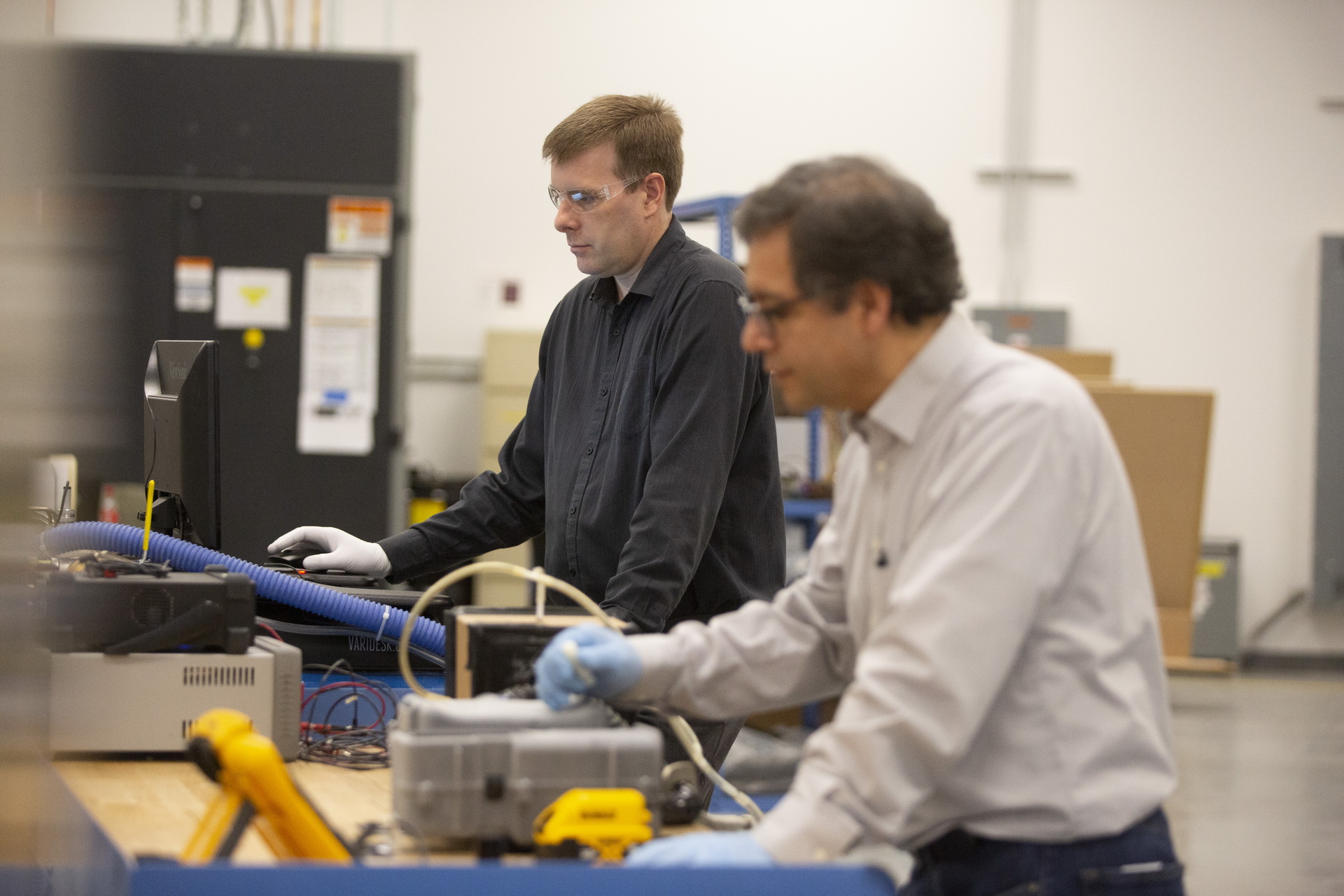

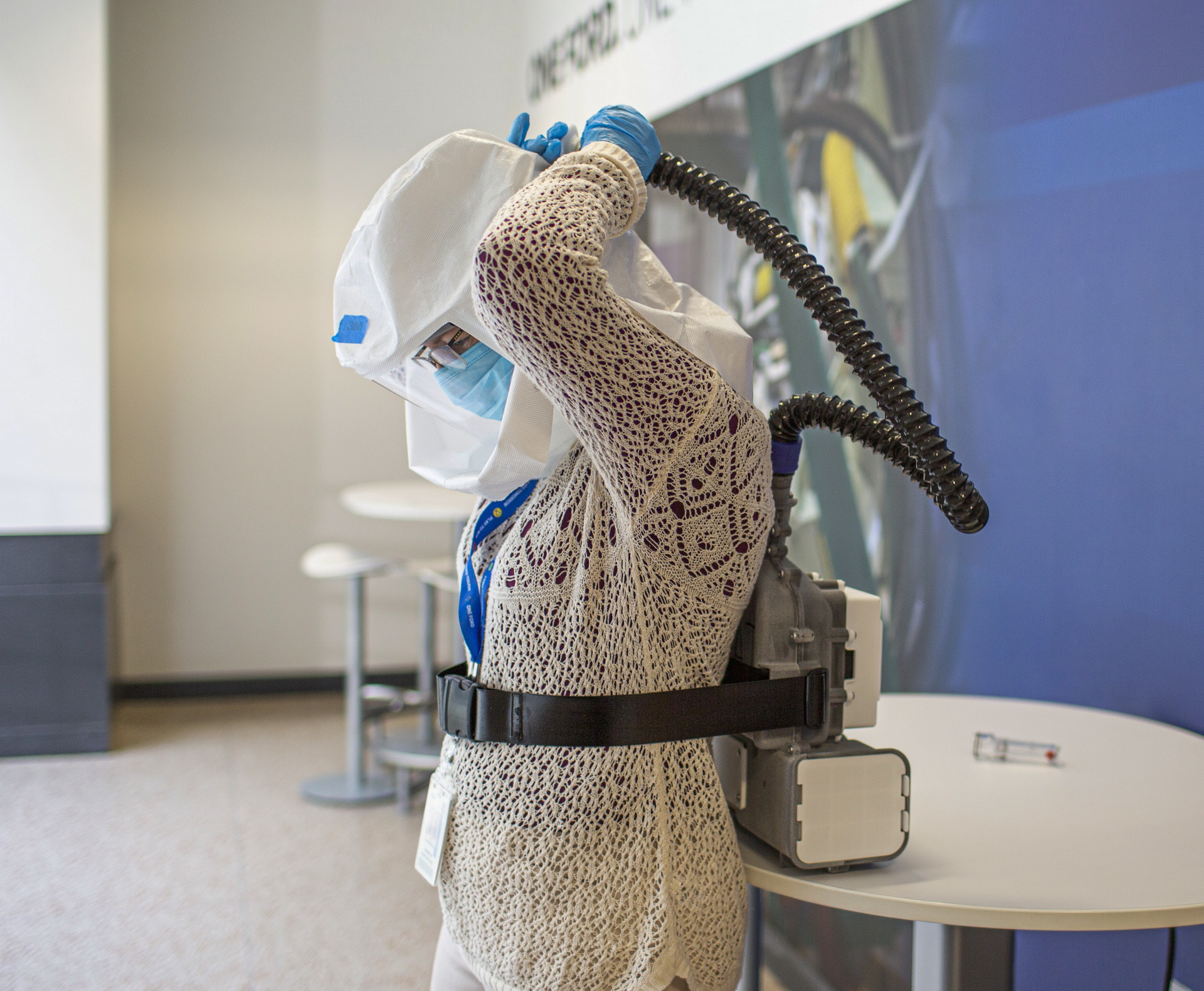

Ford has made more than 3 million face shields in Plymouth, Michigan, while production on the Ford-designed respirator begins today – approximately 90 paid UAW volunteers will assemble the units at Ford’s Vreeland facility near Flat Rock, Michigan, where they’ll be able to make 100,000 or more.

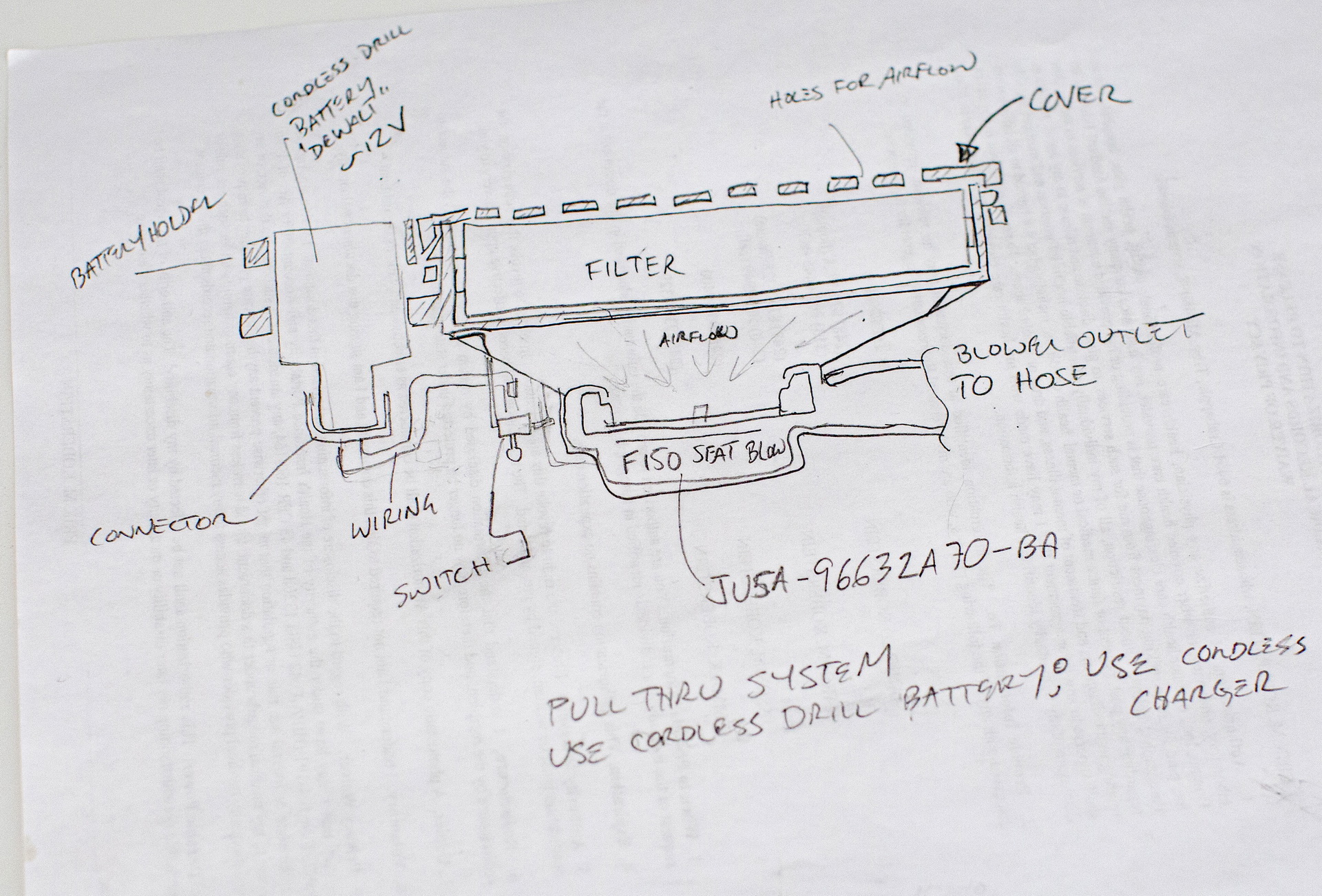

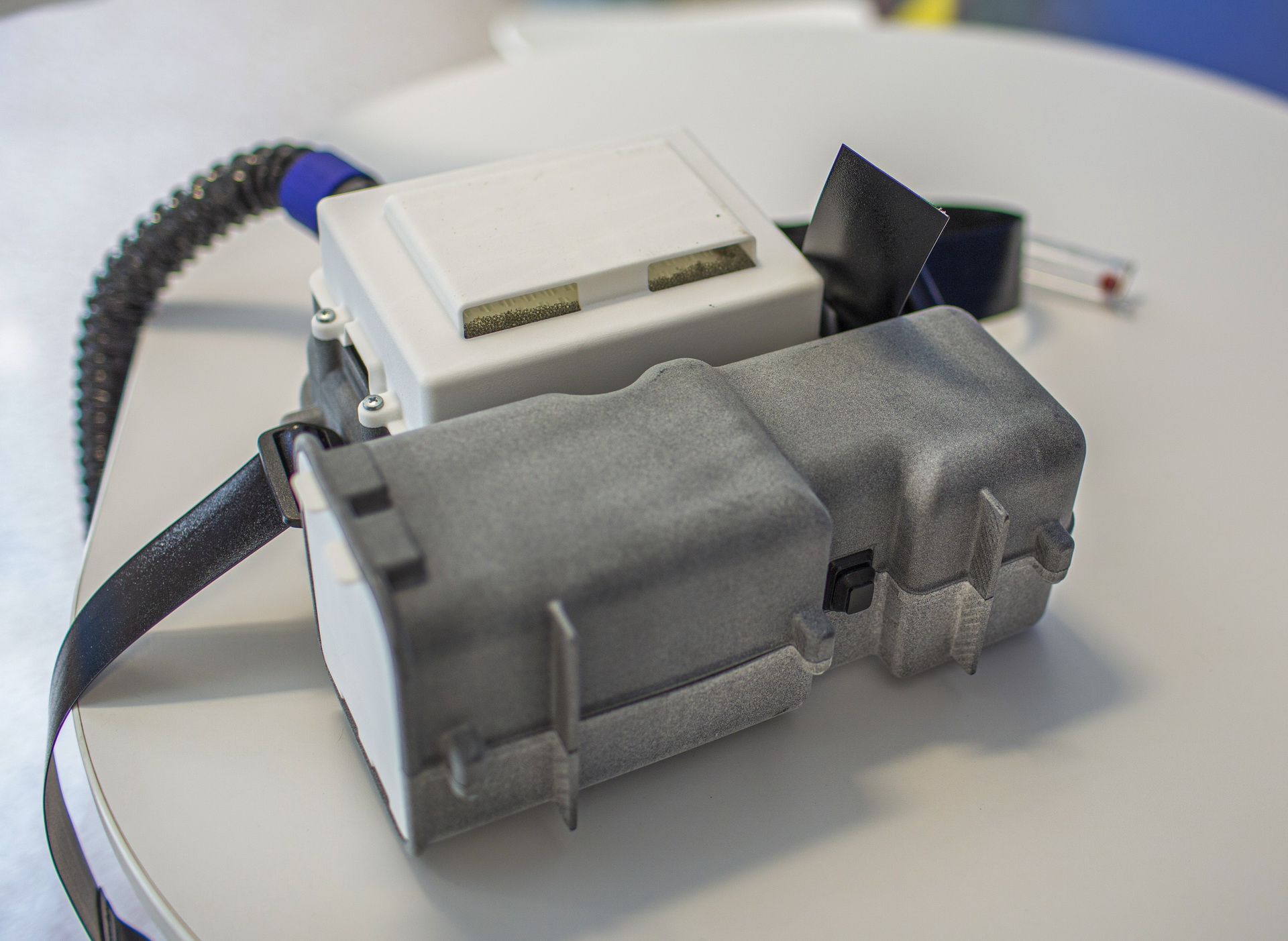

The powered air-purifying respirators (PAPR) feature an air blower system similar to the fan found in the F-150’s ventilated seats. In turn, that system is powered by a rechargeable, portable battery.

Meanwhile, the facemasks are being made by some 30 UAW paid volunteers, in a controlled environment with extremely low levels of pollutants. As for the gowns, the carmaker is aiming to make about 75,000 of them per week, before scaling up to 100,000 by April 19 and beyond. By July 4, Ford supplier Joyson Safety Systems will cut and sew 1.3 million gowns.

The carmaker is also doing its part across the pond, with pre-production activities already underway in the UK, where Ford and an industry consortium will be making ventilators from Penlon. This production will help meet demand for 15,000 ventilators ordered by the UK government.