Porsche has started 3D printing pistons for the 911 GT2 RS and says that they are not only lighter than traditional pistons but also add more power.

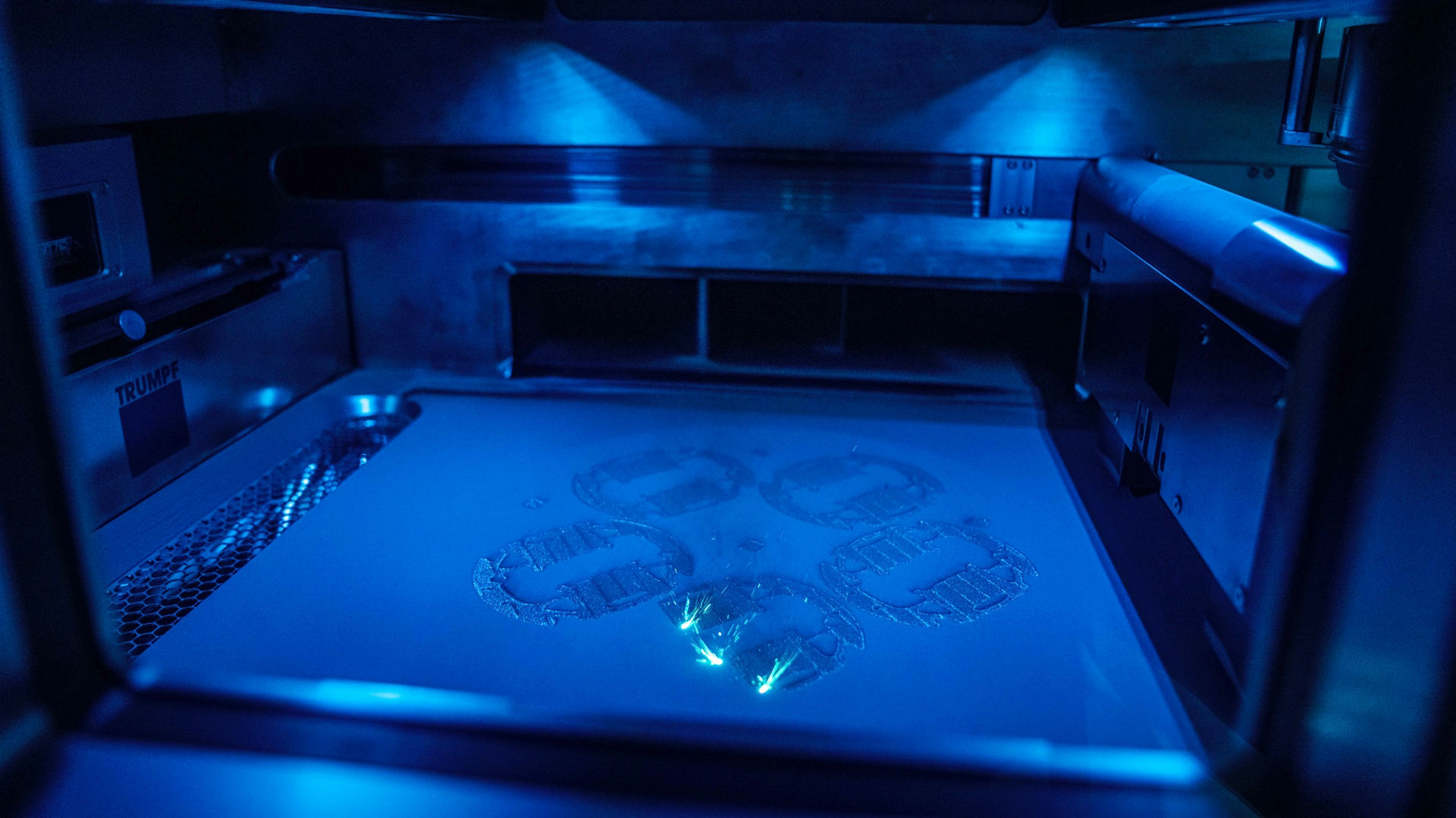

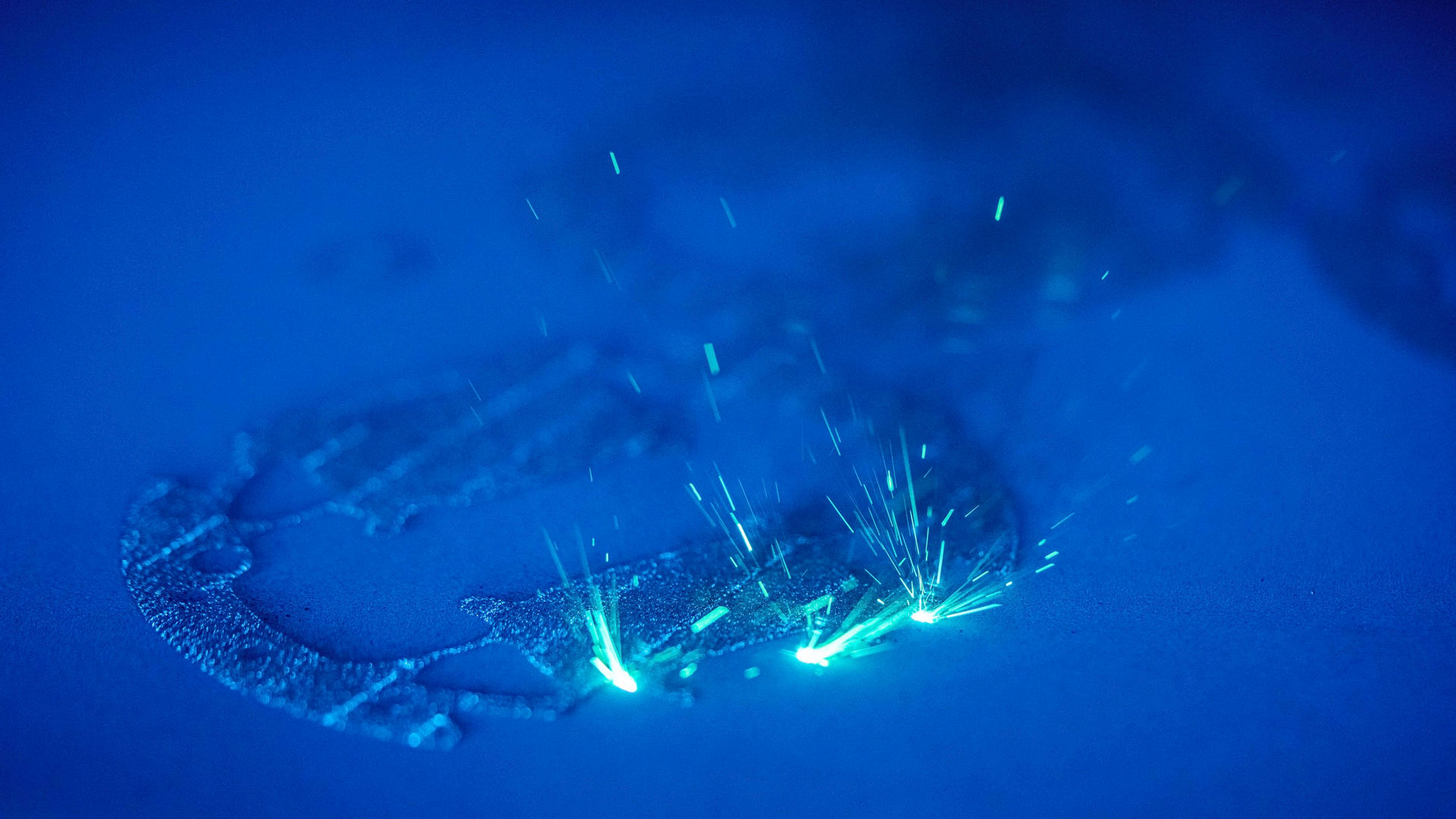

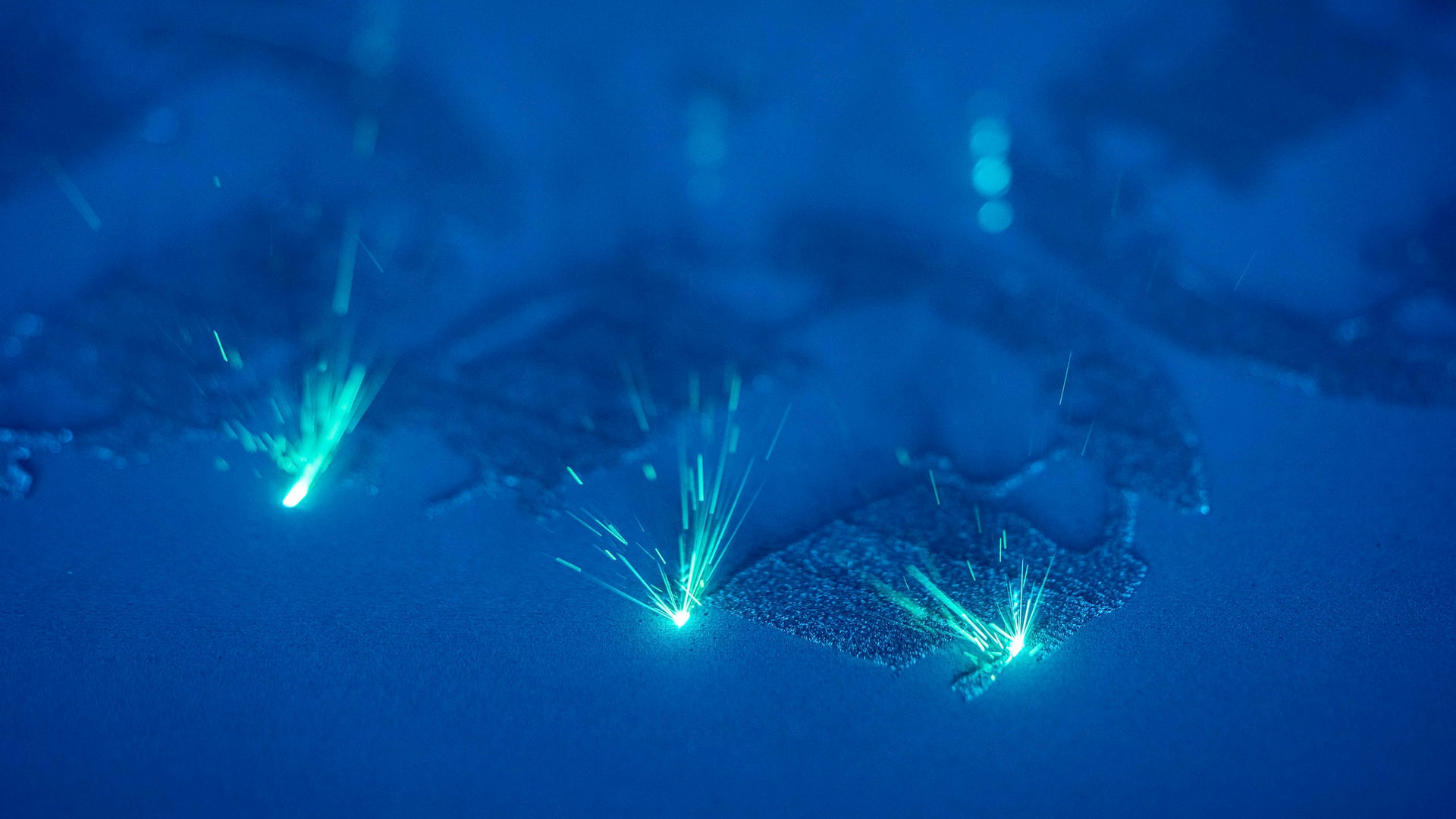

In partnership with Mahle and Trumpf, Porsche uses high-purity metal powder and the laser metal fusion process to create the parts. This process involves a laser beam heating and melting the powder surface corresponding to the part contour. The result is that almost any geometric shape can be 3D printed after design data is sent from a computer.

Watch Also: See Modified Porsche 911 GT2 RS Hit 227 MPH (365 km/h)

Thanks to the 3D printing technology, the new pistons for the GT2 RS are 10 per cent lighter than the forged series production pistons. In addition, the new pistons have an integrated and closed cooling duct in the piston crown. As explained by Frank Ickinger from the advance drive development department at Porsche, the automaker has been able to increase engine speed, optimize combustion and lower the temperature load on the pistons. The result is an extra 30 hp from the twin-turbo 3.8-liter flat-six engine, pushing it from 690 hp up to 720 hp.

This is not Porsche’s first foray into the world of 3D printing. Since May, it has been 3D printing the cushion and backrest surfaces of the bucket seats available on the 911 and 718 Cayman/Boxster models. Additionally, roughly 20 reproduced parts for Porsche classic models are being 3D printed, such as a release lever for the clutch of the iconic Porsche 959.

Porsche has not said if and when it will start selling vehicles with 3D printed pistons.