Bentley has announced a new research project with the aim to transform EV powertrains and remove the need for rare-earth magnets in their construction.

The company’s new study, titled OCTOPUS (which stands from Optimised Components, Test and simulatiOn, toolkits for Powertrains which integrate Ultra high-speed motor Solutions), is funded by UK’s Office for Low Emission Vehicles and will be conducted in partnership with Innovate UK.

Read More: Bentley Begins Assembly Of Blower Continuation Series ‘Car Zero’ Prototype

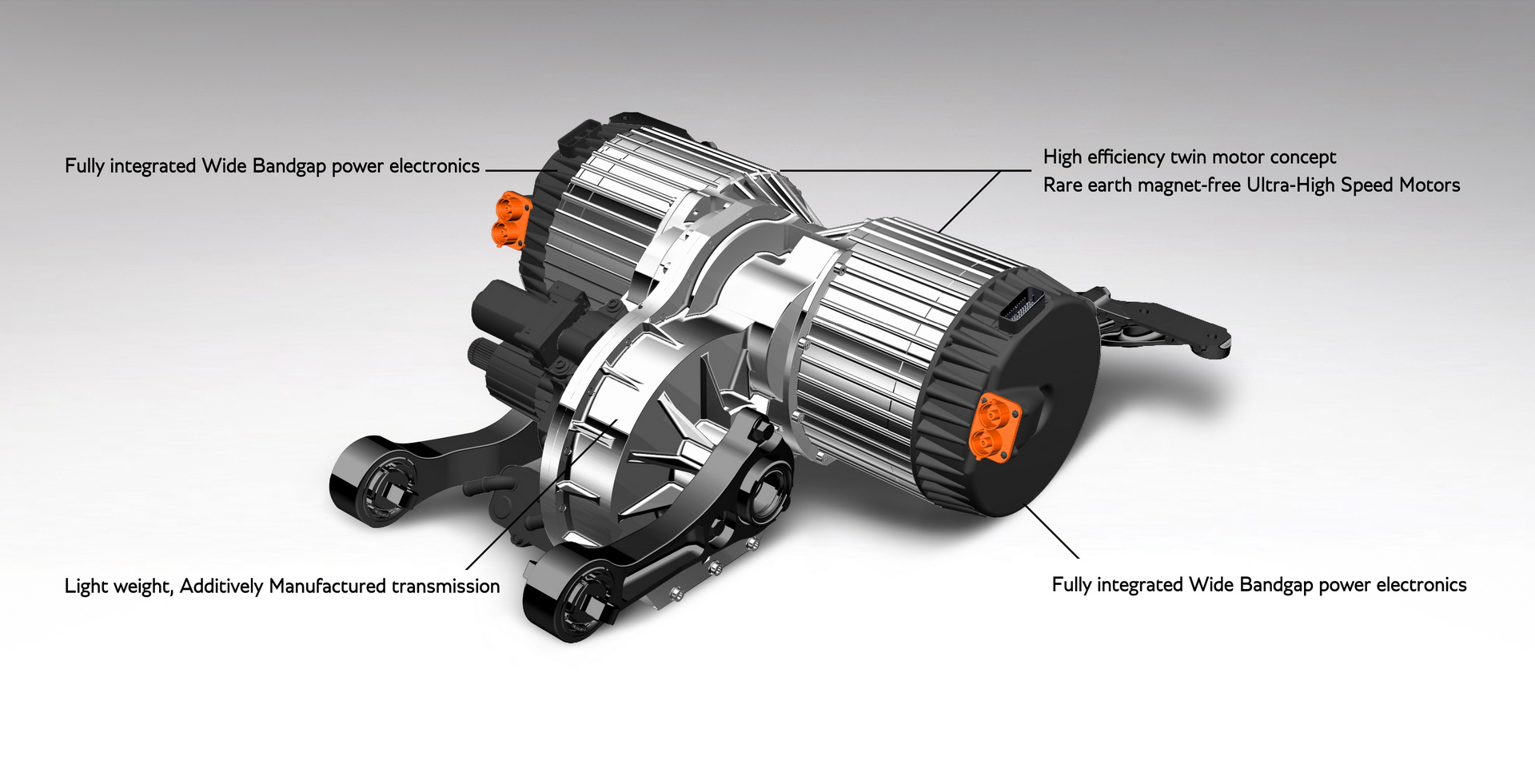

The study follows an 18-month investigation, which found that the proposed electric drive system offers better performance from the latest permanent magnet motors without the need for rare-earth magnets and copper windings, offering a package that’s both cost-effective and recyclable at the end its life cycle.

Bentley’s OCTOPUS research will use this innovative design that includes twin electric motors, power electronics, and transmission packaging and will add next-generation materials, efficient manufacturing processes, along with the necessary simulation and test cycles in order to produce a full e-axle powertrain that features unique levels of integration in EV architectures and “revolutionary” performance levels.

Bentley expects that the new EV drivetrain will be ready for use in a production vehicle by 2026, the same year the carmaker has said they will introduce their first electric model.

“With the industry, technologies, and cars changing faster than ever before, research projects such as OCTOPUS are crucial to deliver innovative technologies and overcome challenges for the next generation of mobility solutions,” said Stefan Fischer, Bentley’s Director of Powertrain Engineering.