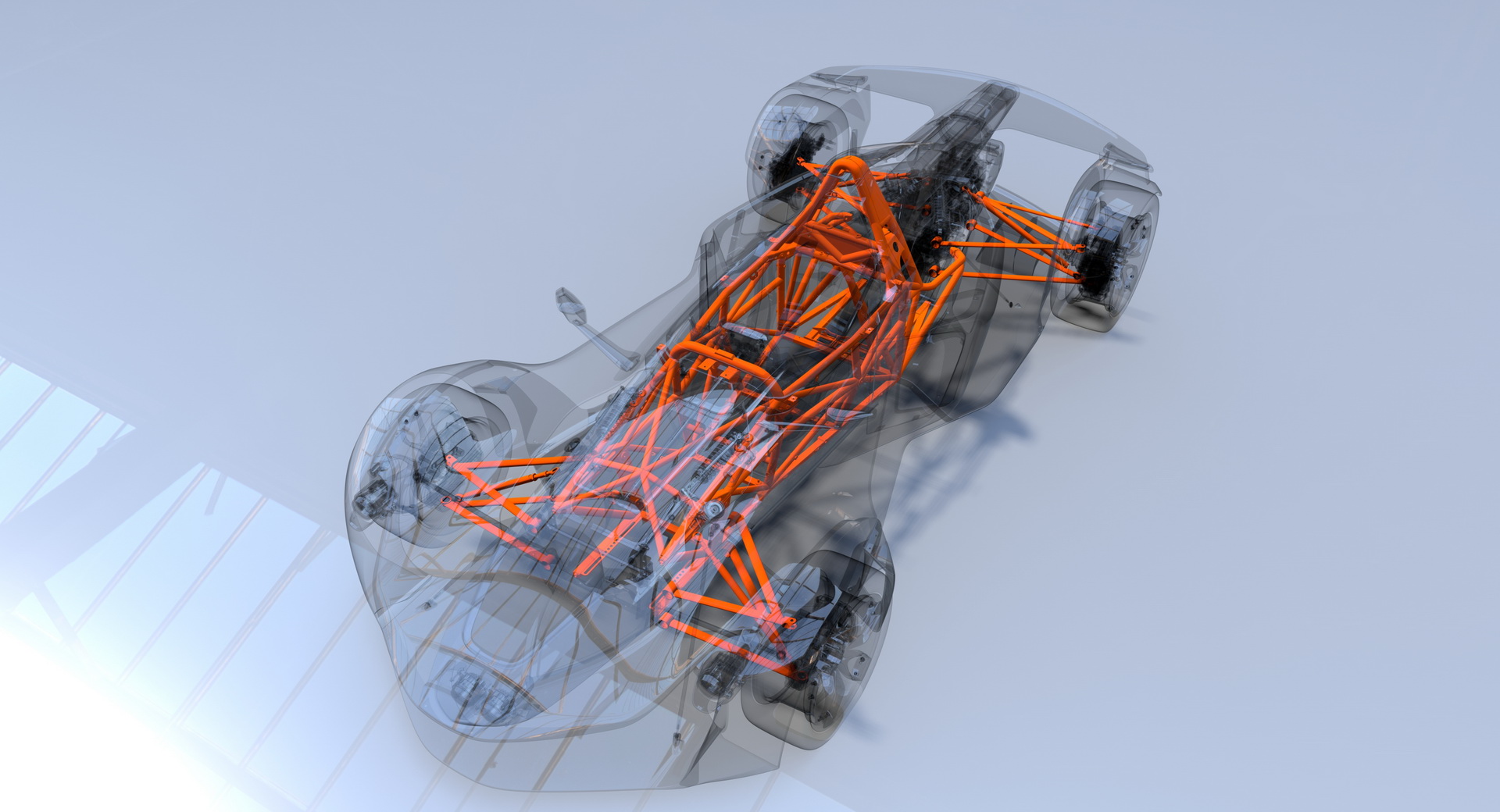

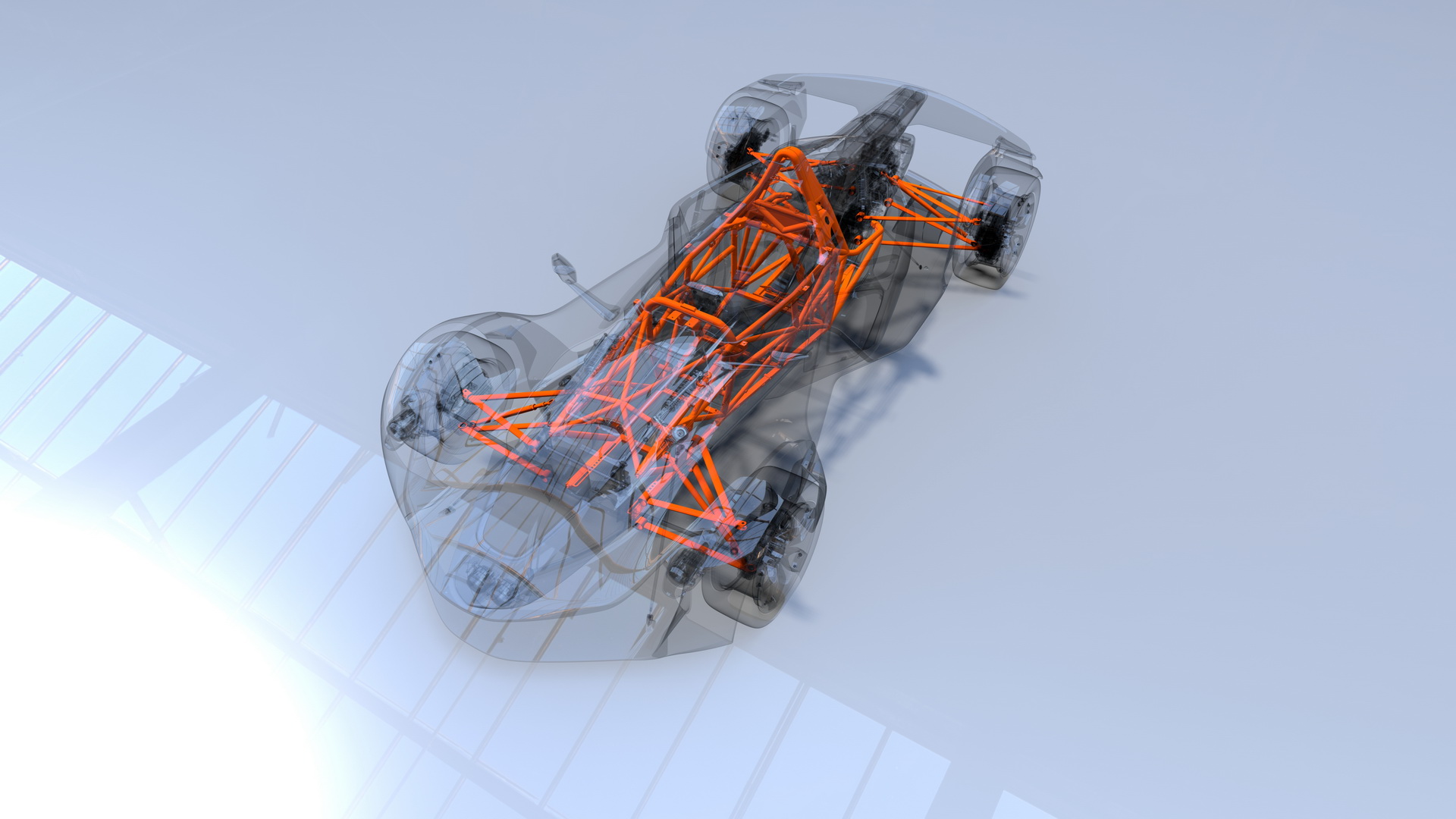

BAC has been awarded funding for a new project that will see them implement the use of nano element ‘Niobium’ in the structure of the BAC Mono.

Niobium is a naturally occurring, readily available element that is “ductile, malleable and highly resistant to corrosion.” It is said to enhance the mechanical properties of alloy metals and it’s already been used in Jet engines, rockets and building structures.

This project however will mark the first time that Niobium has ever been used in the automotive sector.

Read Also: All-New BAC Mono Breaks Cover With 332 PS, 0-60 In 2.7 Sec

The British carmaker is looking for proof of concept by developing and producing structural prototype systems. If successful, the next stage will see them implementing Niobium into full production.

“We’re incredibly excited about our latest nano element R&D project and once again looking forward to putting BAC on the map as true pioneers of the automotive industry. BAC is all about revolutionary technology and pushing the boundaries of what’s possible, and using Niobium-enhanced structures is just another innovative way we’re finding crucial weight-saving solutions for the Mono supercar.”

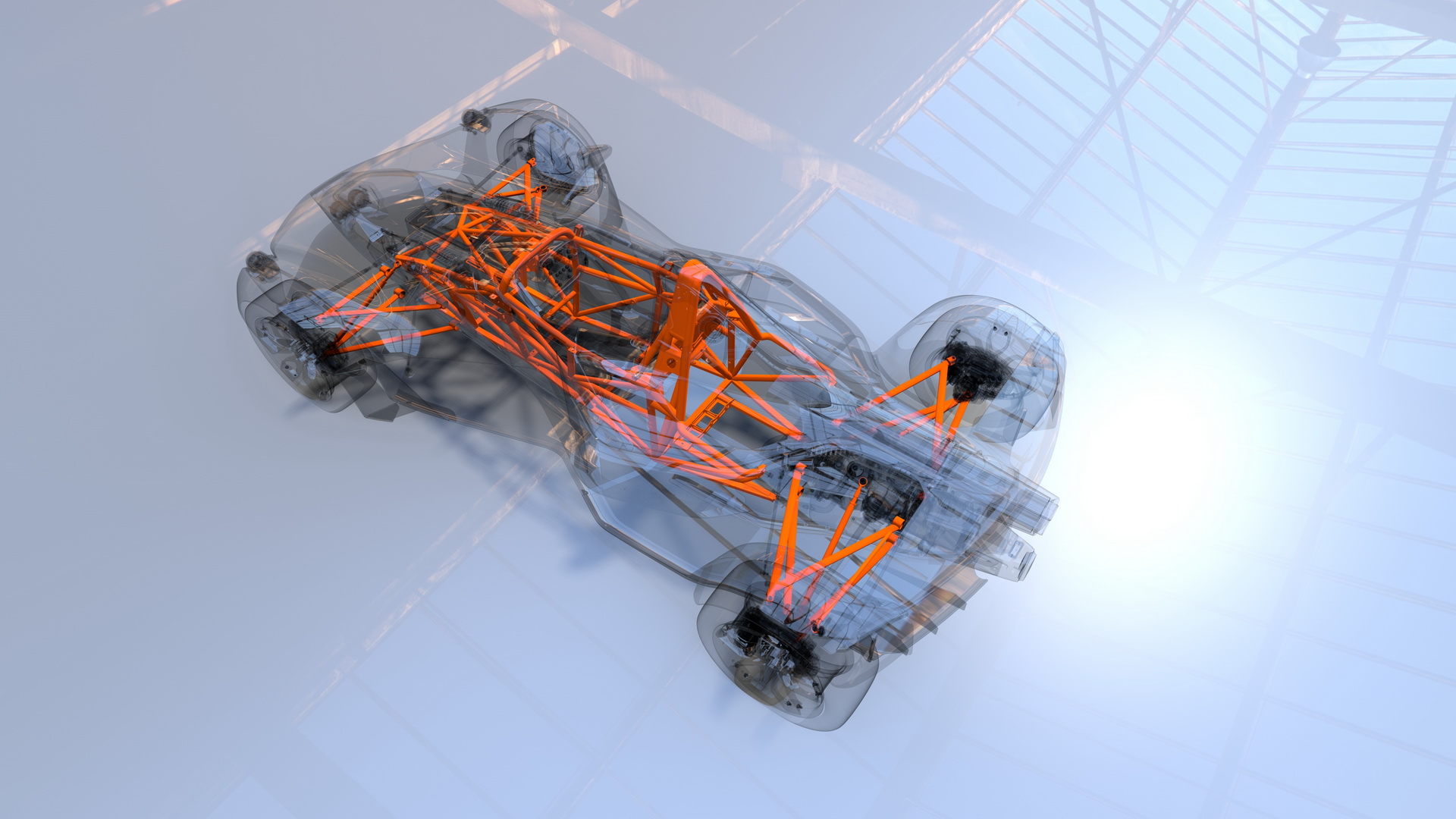

Of course, the Mono is no stranger to weight-saving, after all, the latest model costs $212,000 for a reason. It tips the scales at just 1,256 lbs (570 kg) and has a power to weight ratio of 582 PS (574 HP) per tonne thanks to its 2.3-liter 332 PS (327 HP) engine.

The project is sponsored by CBMM, a Brazilian firm that’s also involved with Formula E. More recently, they also became the founding supplier of Extreme E racing, launched by Lewis Hamilton.