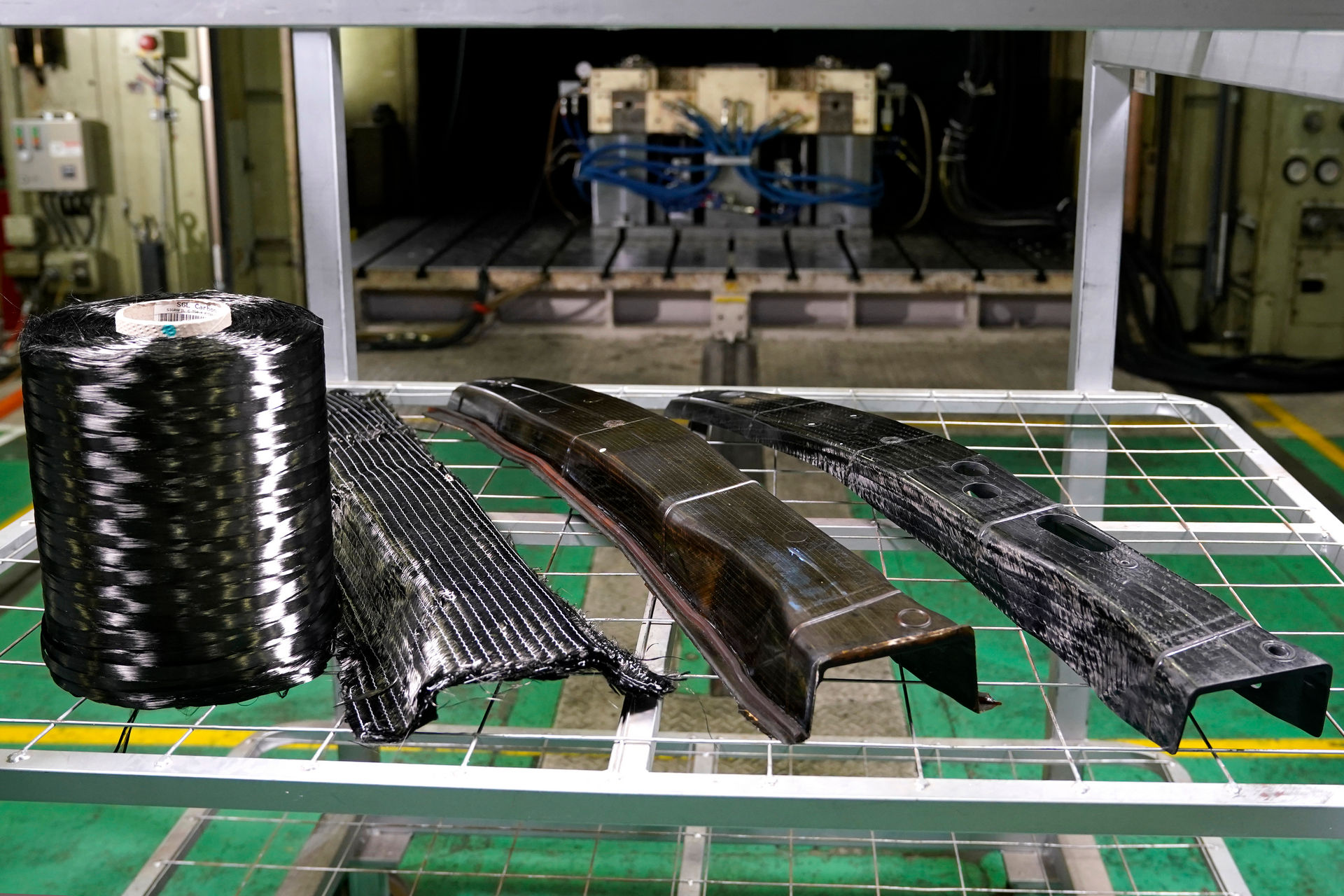

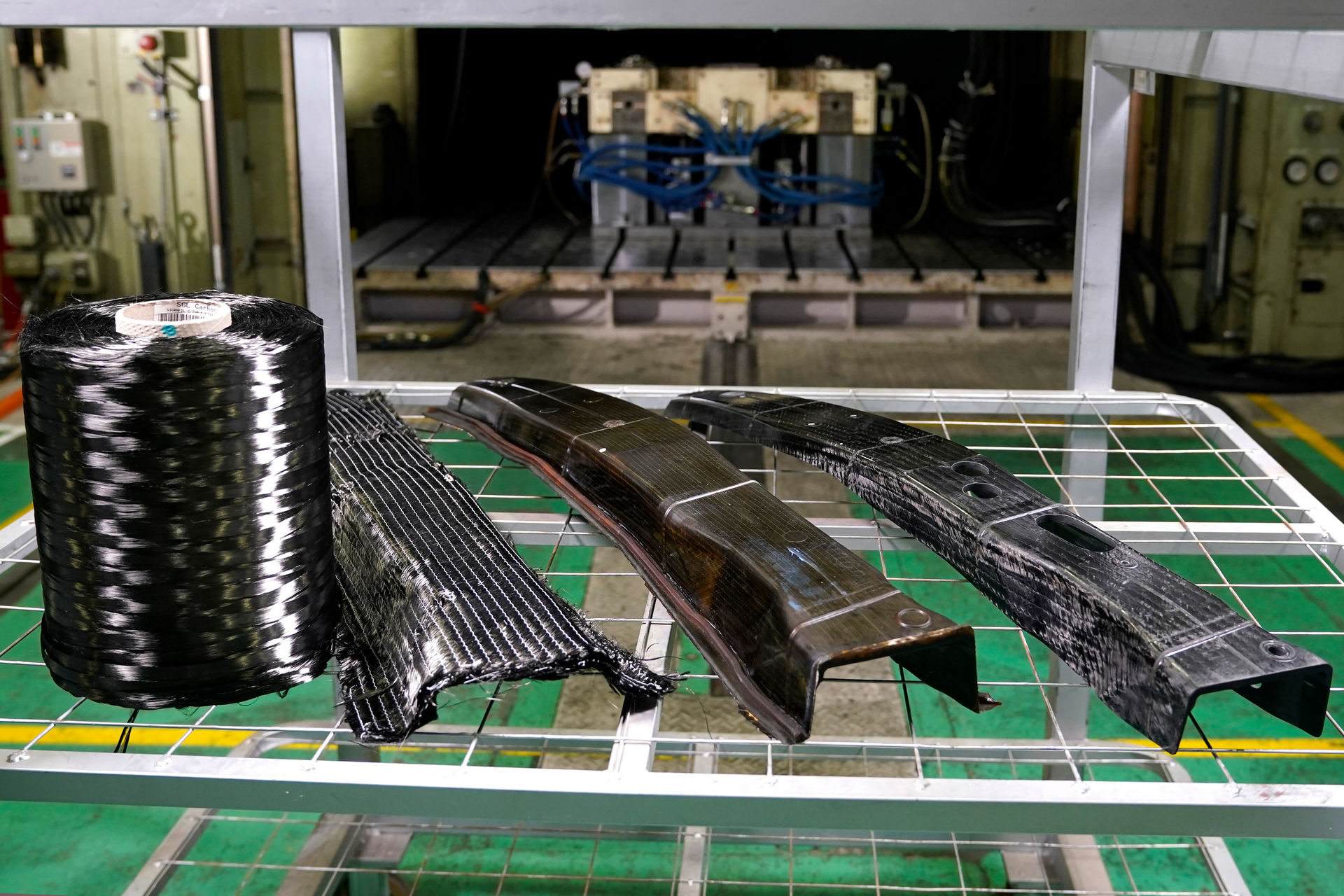

Nissan says it has achieved a breakthrough in the production of carbon fiber that will help the material find its way into more mass-market vehicles.

We all know about the advantages of carbon fiber over some more traditional and affordable materials. Most notably, it is exceptionally light while still being strong and is the perfect material to make vehicles safer and lighter which in the end benefits fuel efficiency. Less weight also improves performance.

Of course, carbon fiber is expensive and the costs have prevented it from becoming mainstream in the mass-market automotive industry. Now, Nissan has found a new approach to producing carbon fiber known as compression resin transfer bolding.

Read Also: Nissan Reveals Magnite Concept’s Interior, Production Model Should Look Largely The Same

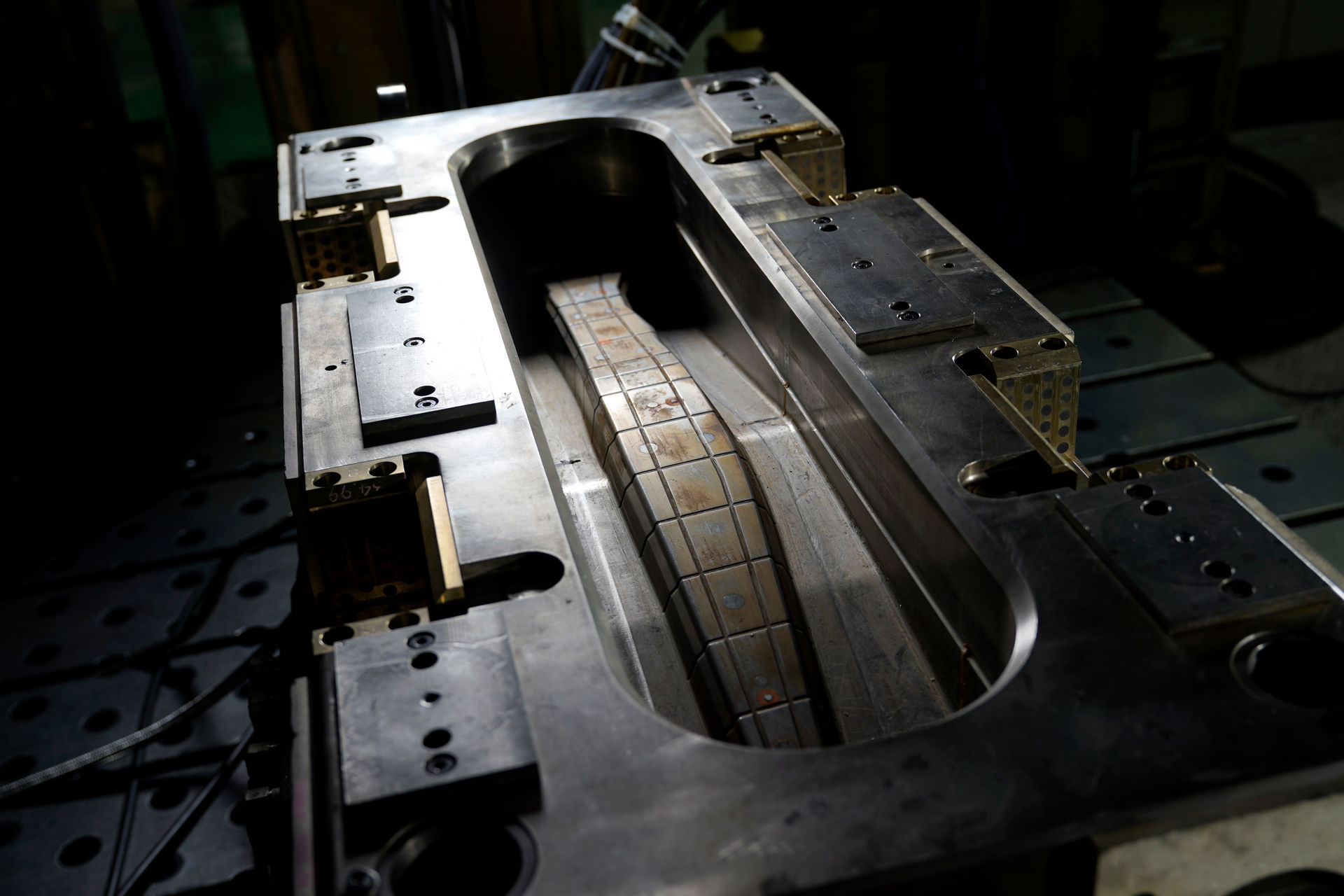

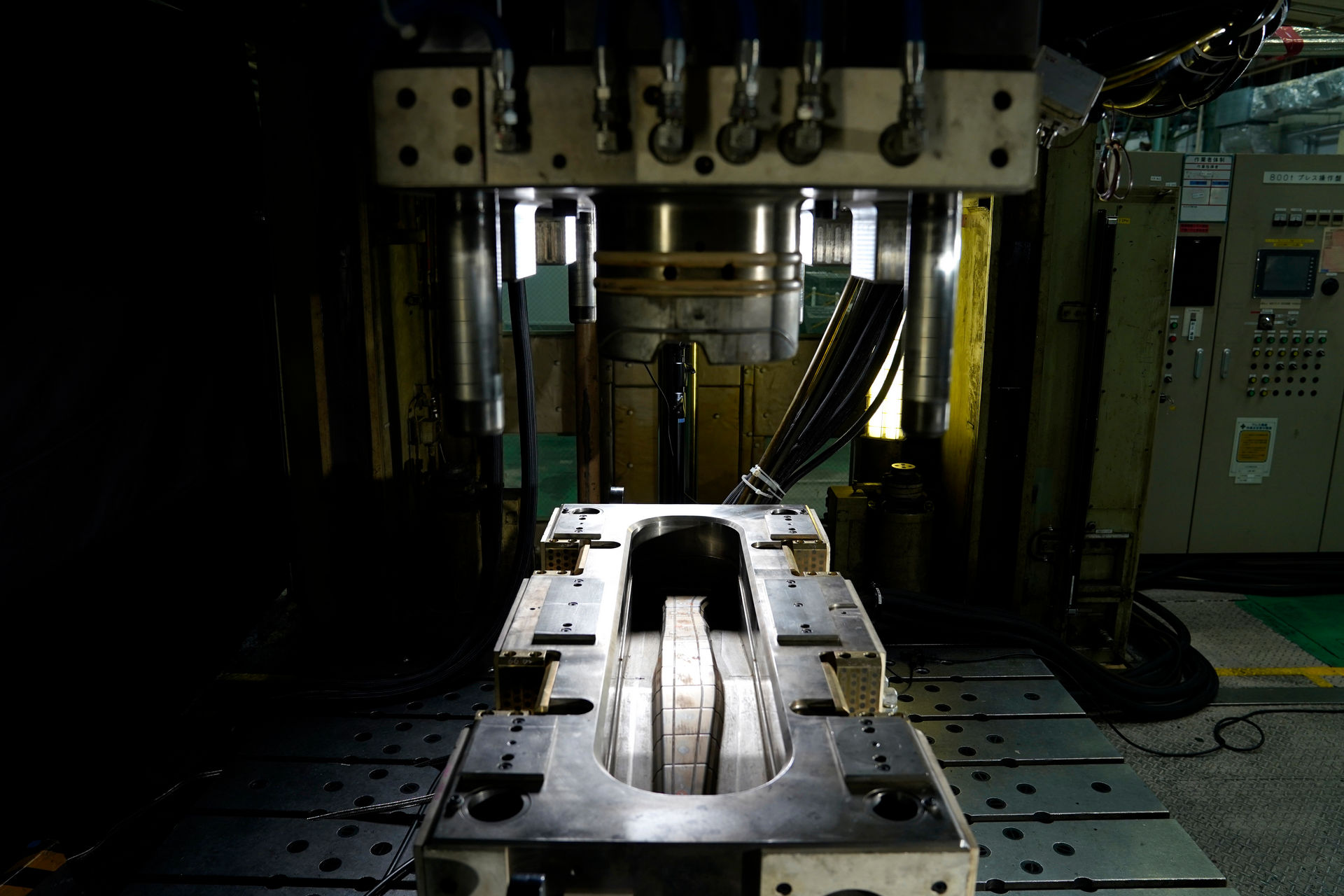

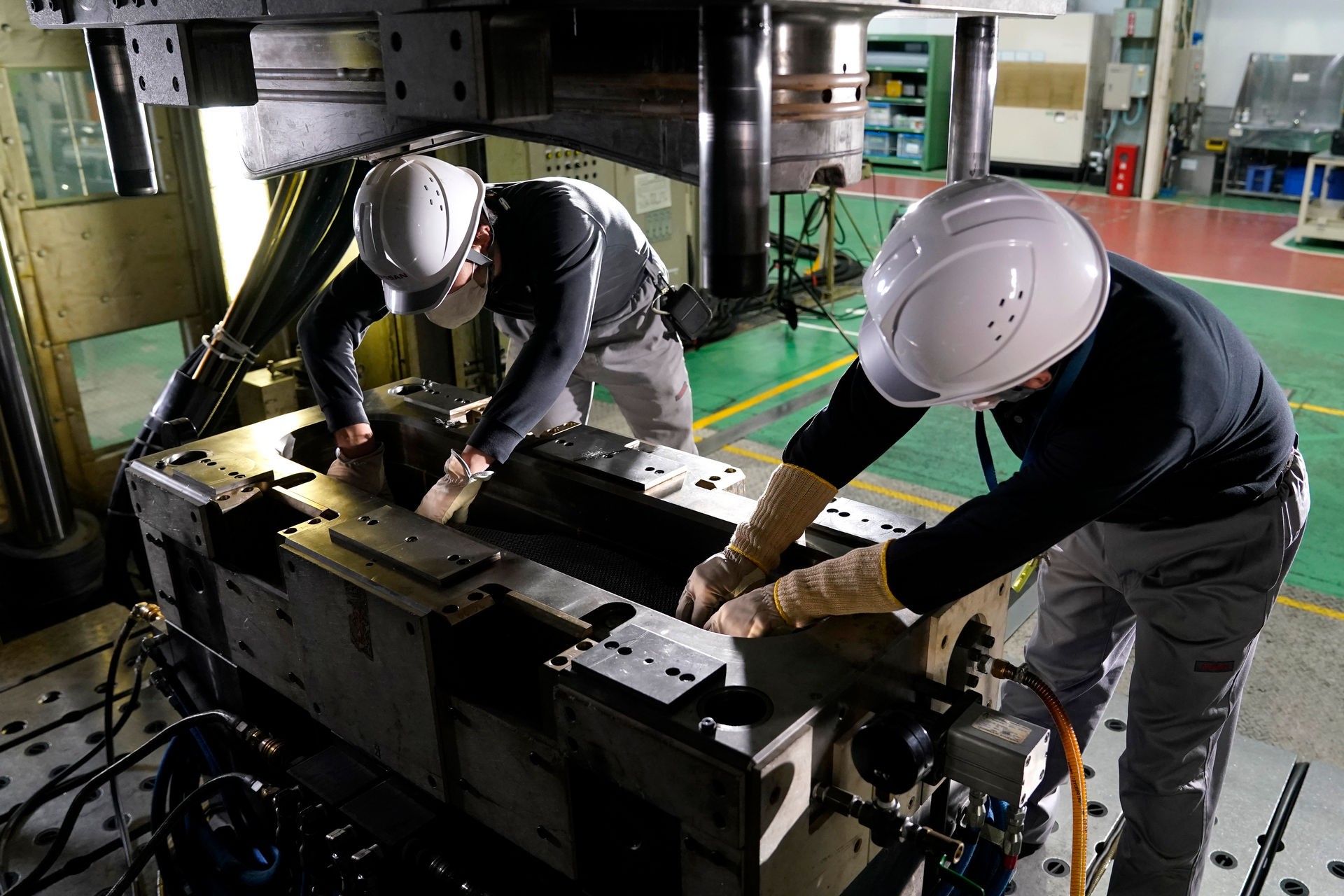

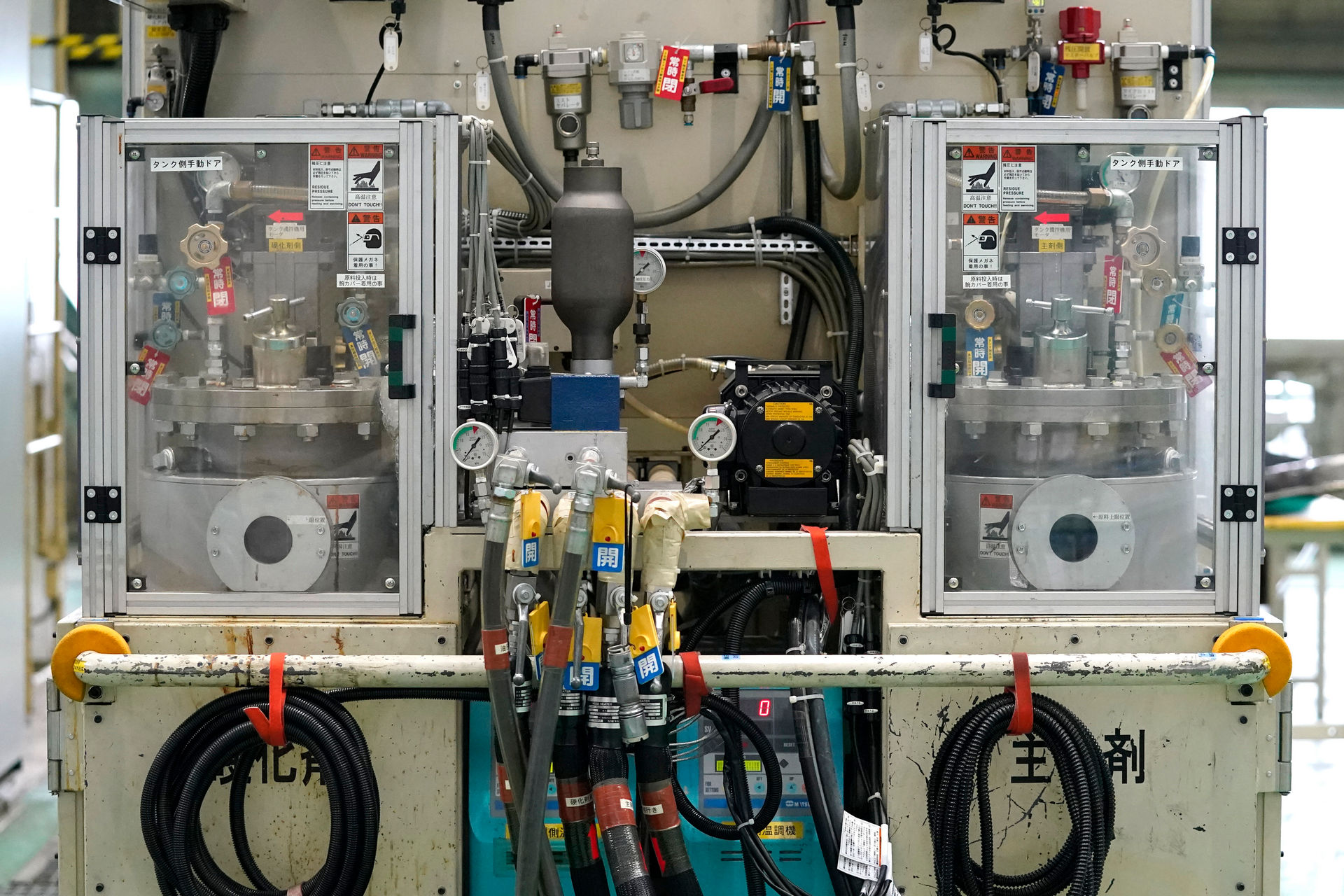

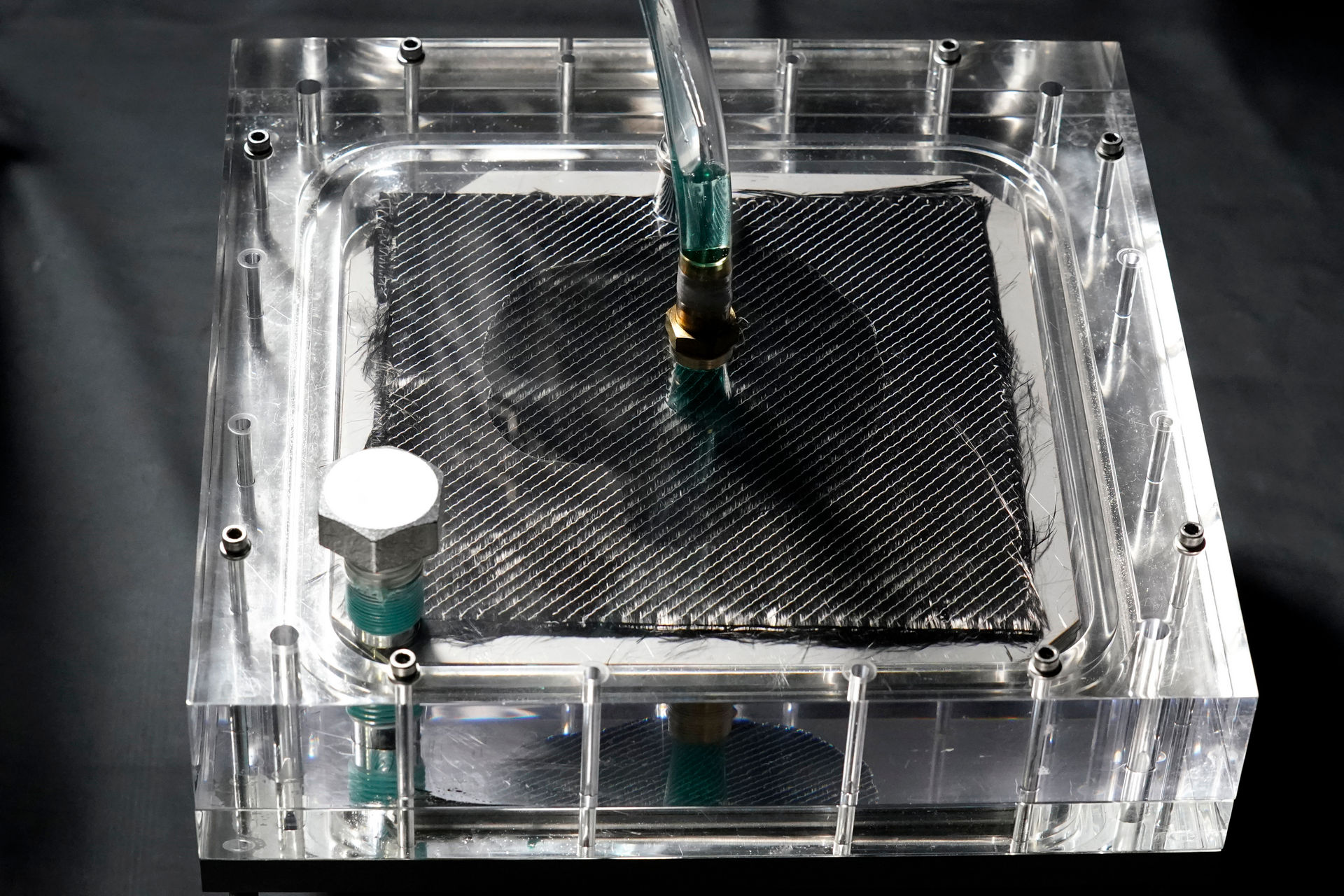

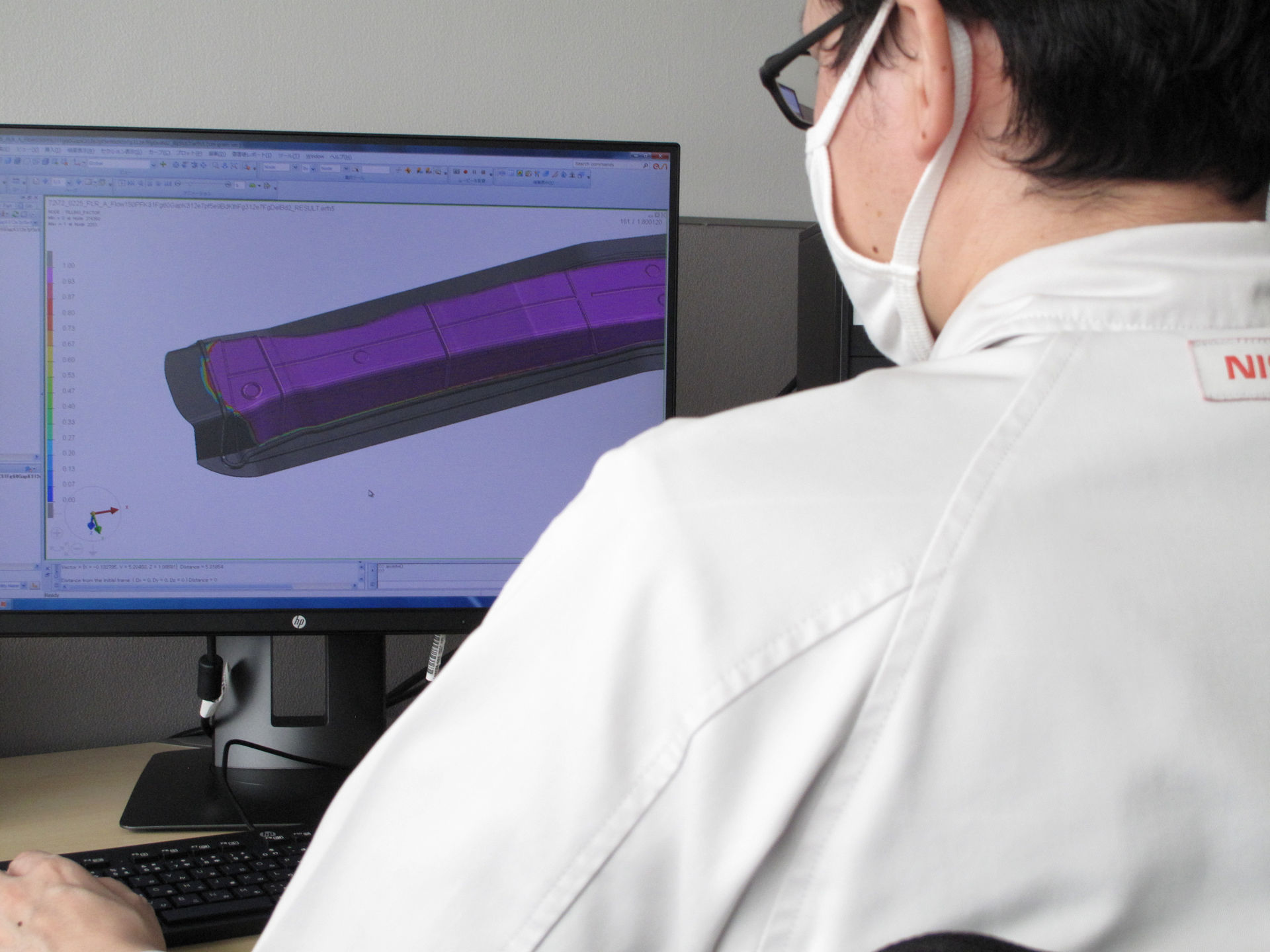

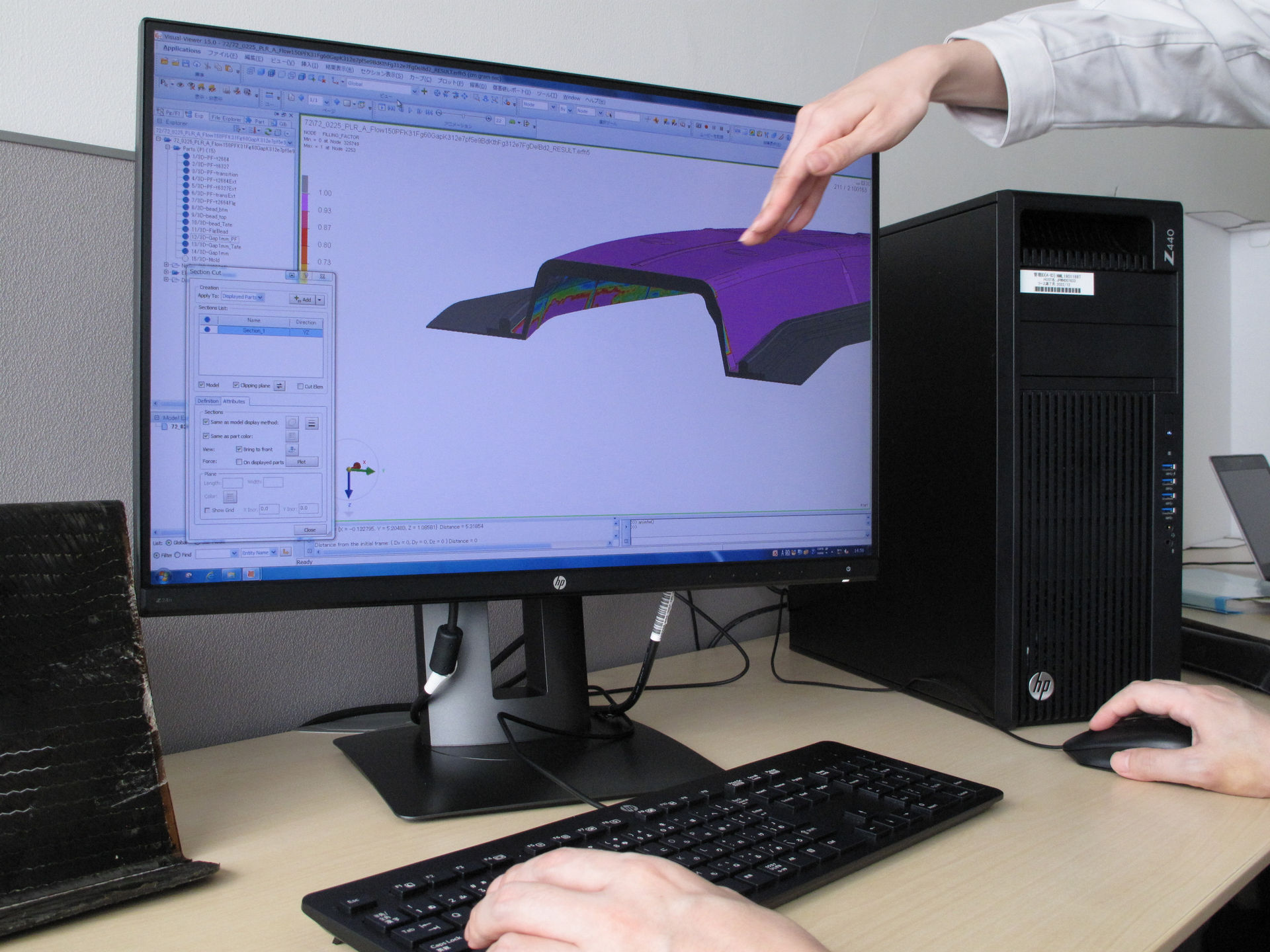

This method involves forming carbon fiber into the right shape and setting it in a die with a slight gap between the upper die and the carbon fibers. Resin is then injected into the fiber and left to harden.

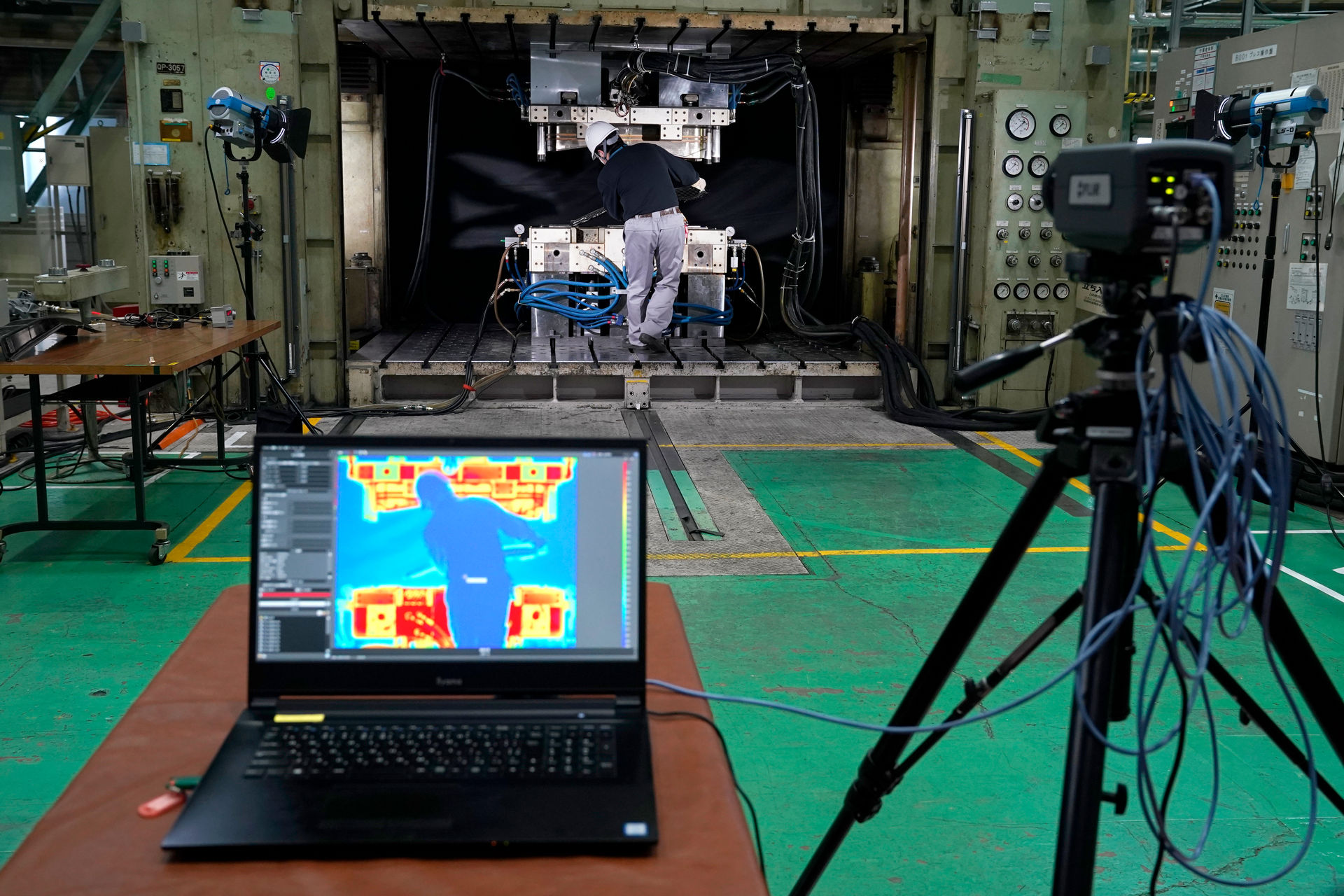

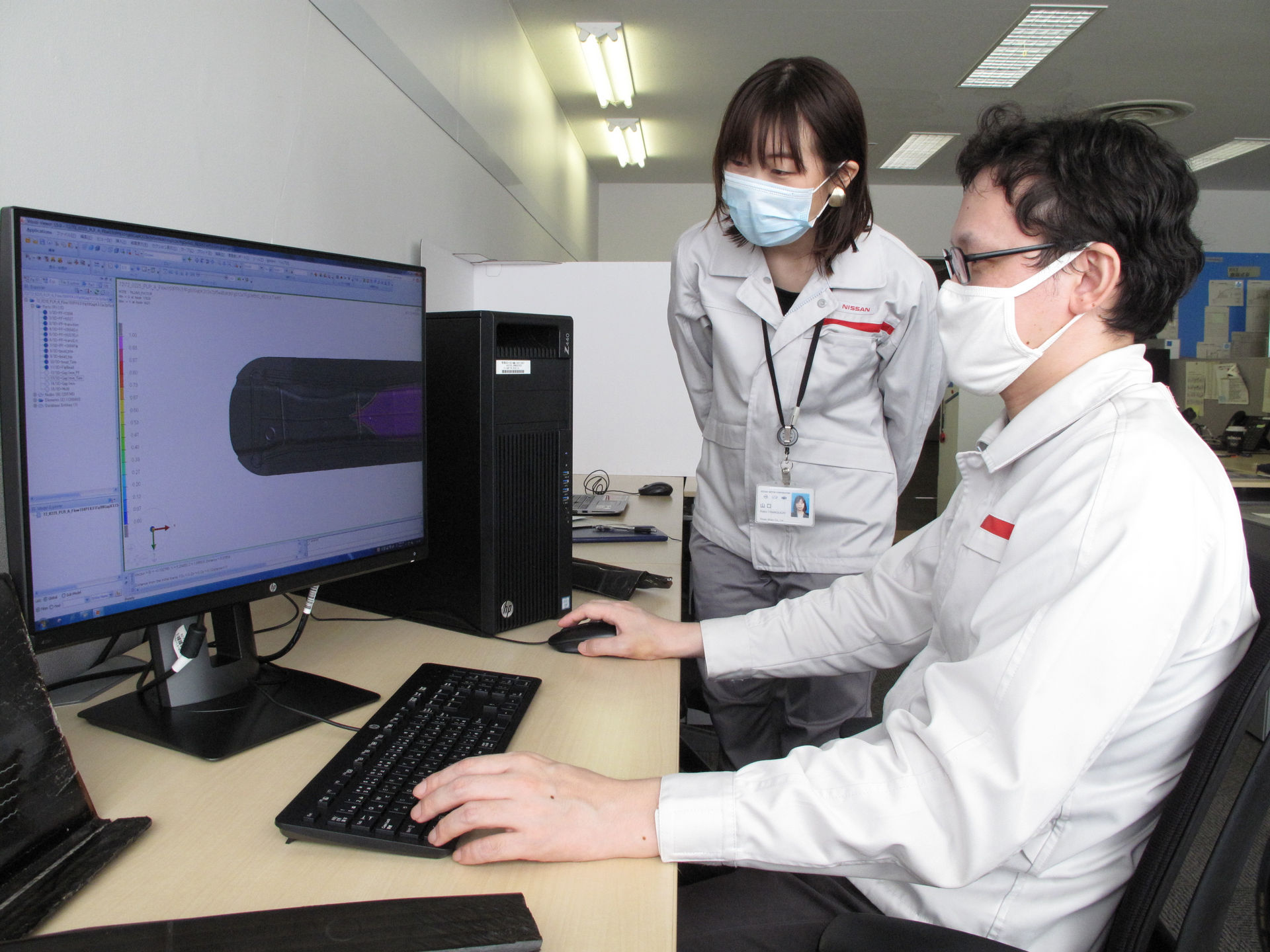

The Japanese automaker adds that it has developed techniques to simulate the permeability of the resin in carbon fiber while also visualizing resin flow behavior in a die using an in-die temperature sensor and a transparent die. This culminates in shorter development times for the carbon fiber parts.

Nissan has yet to state what it intends on doing with carbon fiber in the immediate future. Given the company’s ongoing financial troubles, we suspect it’ll be some time before carbon fiber becomes a standard feature on affordable Nissan models. In all likelihood, it will be put to use in more expensive models like the forthcoming 400Z first.