The largest automotive plant in the world, operated by one of the largest automakers, has seen production plummet in 2021 as a result of supply-related issues.

Sources at Volkswagen told Reuters that the Wolfsburg plant has produced just 300,000 vehicles so far this year, the lowest figure it has recorded since 1958. The plant has averaged production figures of 780,000 vehicles per year over the past decade and before the pandemic had intended to up that figure to a million per year.

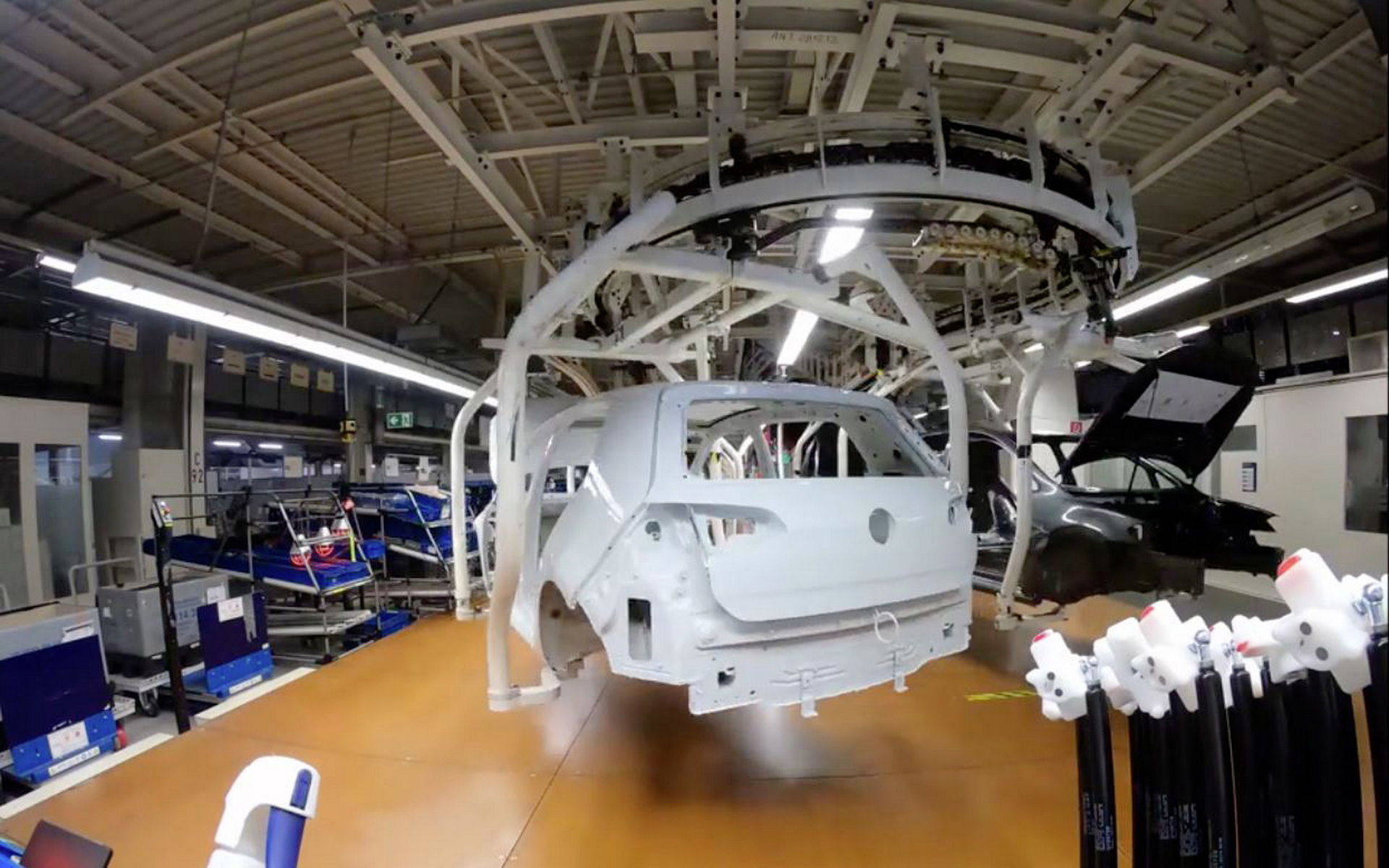

Supply chain issues, specifically a lack of semiconductor chips, have restricted VW’s ability to produce vehicles at the plant, which makes the Golf and the Tiguan, among other vehicles. In 2020, the combination of the pandemic and the related chip shortage meant that the plant only managed to produce 500,000 vehicles, a figure it’s unlikely to match this year.

Read Also: The Chip Shortage Could Cost The Auto Industry $210 Billion This Year

Volkswagen has said previously that it was expecting a production shortfall in the high hundreds of thousands as a result of the semiconductor chip shortage. It is hardly alone in its difficulties, as supply issues affect practically all manufacturers.

It is estimated that the chip shortage will result in 7.7 million fewer vehicles built this year and cost the industry around $210 billion. Although automakers are intent on finding a solution to the problem and governments have stepped in to try and address it, even the most optimistic onlookers expect semiconductor supply to be problematic into 2022.

In the U.S., as supply chain troubles continue to affect automakers’ ability to make new vehicles, dealer inventories have struggled, leading to inflated prices. The combination of high prices and few options is leading many American buyers to delay their plans to buy a new vehicle until after supply returns to normal levels.