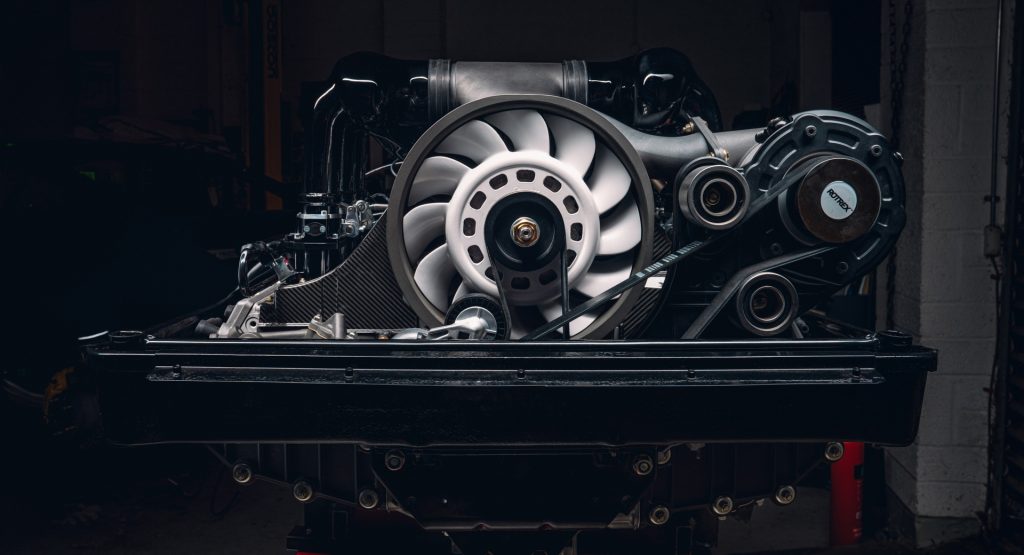

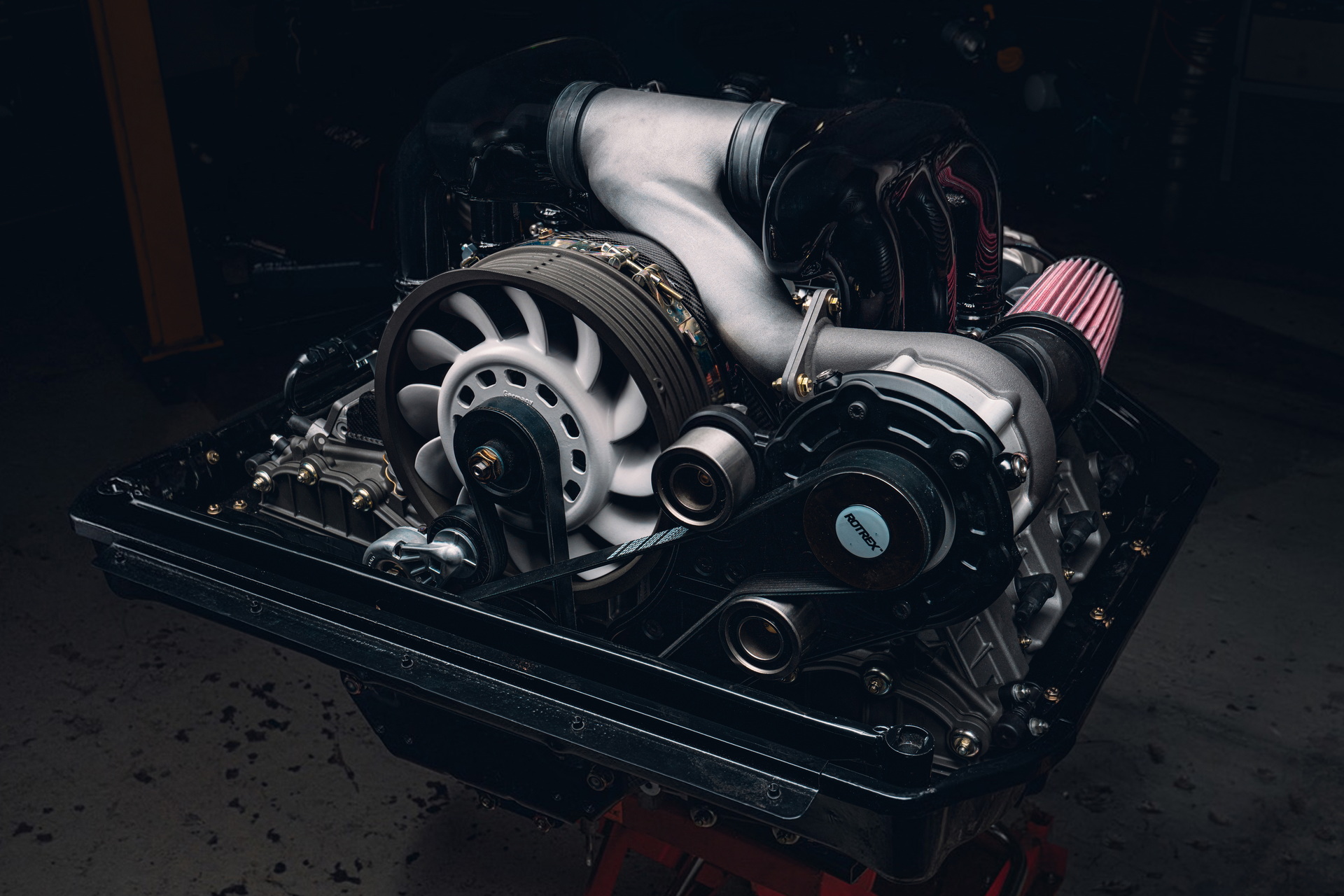

Theon Design has today unveiled its take on a “sympathetically supercharged” 3.6-liter flat-six that will go into a restomodded Porsche 964 911. The engine is capable of delivering 450 hp (456 PS/335 kW).

“We wanted to deliver additional performance but also maintain the seamless delivery of a Porsche naturally-aspirated engine, so chose a Rotrex centrifugal supercharger,” said Adam Hawley, Theon Design’s founder. “Effectively a belt-driven turbocharger, it gives a wonderful, linear power delivery and instant throttle response with no delay or lag.”

The company chose a Rotrex supercharger for its broad, linear power delivery as well as its size. “As every Porsche enthusiast knows, there’s not a great deal of room within the 911 964 engine bay,” said Hawley.

Read Also: All-Electric Porsche 911 Has A Tesla Motor And A Custom Battery Pack

As a result, the supercharger is placed in the space previously taken up by the original air-conditioning unit. The team used some of the existing A/C brackets to affix the unit to the engine, but also designed some bracketry of its own, mimicking Porsche’s materials and design.

Significant effort was taken to ensure that quality remained OEM-spec, with durability and support a priority to ensure that no movement or flex was allowed within the engine bay. To maintain a clean look, meanwhile, Theon Design opted not to fit an intercooler and chose to install a water-methanol injection system instead.

“Injecting a water-methanol mix into the engine plenum not only provides the same cooling function as an intercooler but also increases the octane rating of the fuel, boosting 98 octane petrol to a 110 rating and improving performance as a result,” said Hawley.

That, too, was designed to fit in with the original aesthetic of the engine bay, with a 3D carbon printed section to bridge the plenums, to complement the carbon fiber engine and fan shroud. All non-essential parts were also removed from the engine bay to tidy it up and ditch some weight.

Lovingly handcrafted, each engine that Theon Design works on is stripped down and every component is checked for quality. Every engine build requires between 150 and 250 hours, and each engine spends a minimum of four hours on the dyno to bed in and to verify power and torque outputs. Once in the car, road testing can begin.

“Road testing is key to ensuring perfection,” said Hawley. “Each commission is driven over a huge variety of road conditions, from town centers, B-roads, A-roads, and motorways. Every car must be as happy being driven at crawling speed around a busy supermarket car park as it is at high speed.”

Theon Design also offers naturally aspirated versions of the engine. Its 3.6-liter unit makes 285 hp (289 PS/212 kW), its 3.8-liter unit offers 370 hp (375 PS/276 kW), and its 4.0-liter unit churns out 400 hp (405 PS/298 kW).

The engine that you see below is set to undergo testing soon, and Theon Design promises that the vehicle it goes into will be revealed in the coming months.