Volvo announced today that it will invest SEK 10 billion ($1.09 billion at current exchange rates) in the coming years at its Torslanda manufacturing plant in Sweden. The money will go towards preparing the site to build the brand’s next generation of electric vehicles.

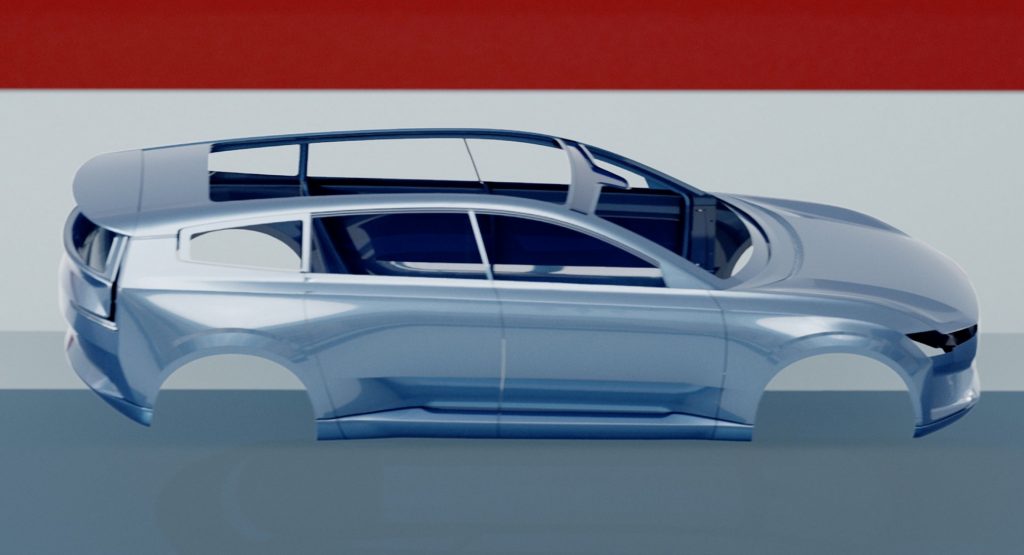

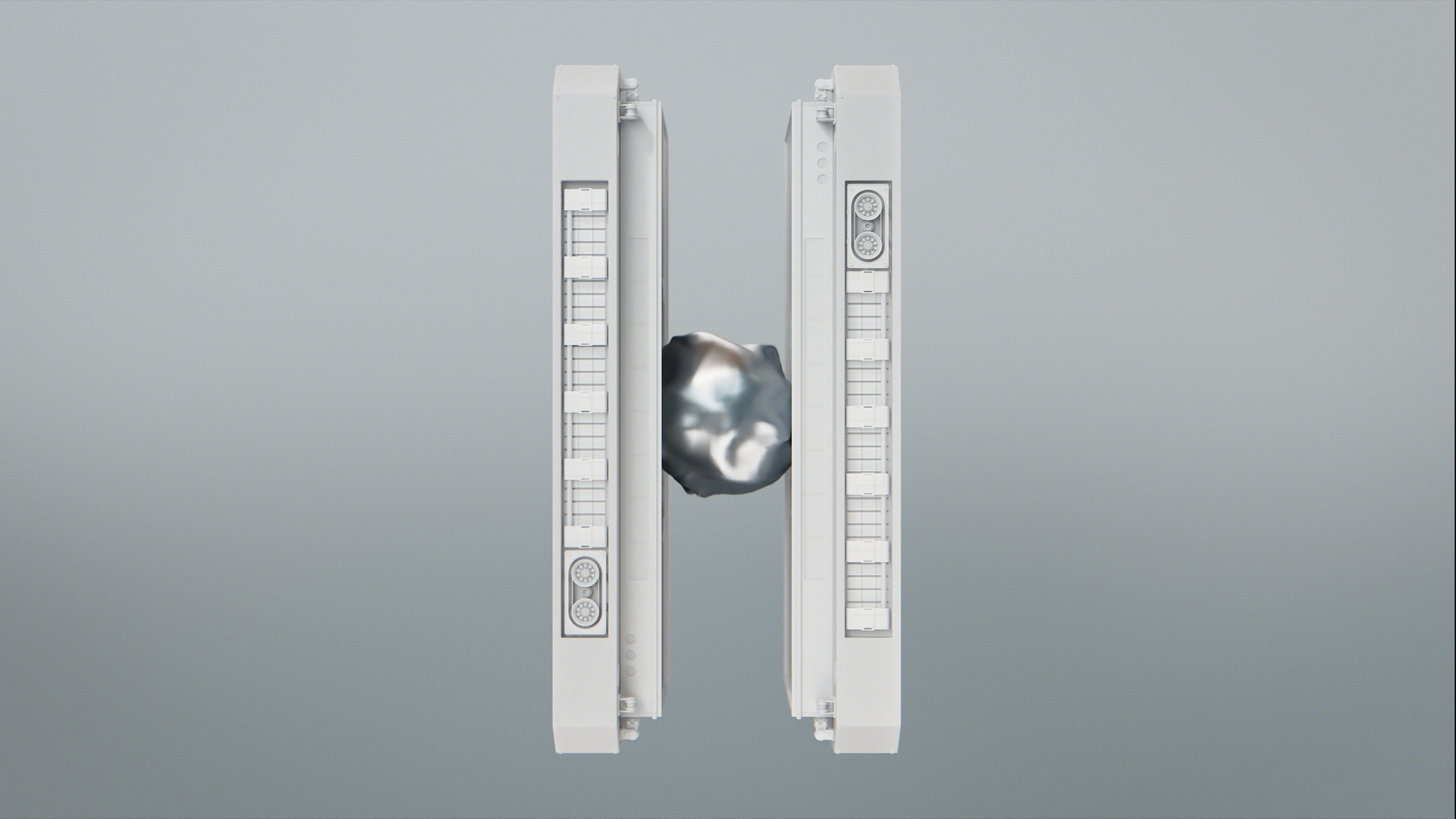

As a result of the expenditure, Volvo will not only install battery-making facilities and reduce the energy consumption in its paint shop, but it will also introduce a mega casting site for aluminum body parts.

“With these investments, we take an important step towards our all-electric future and prepare for even more advanced and better electric Volvos,” said CEO Håkan Samuelsson. “Torslanda is our largest plant and will play a crucial role in our ongoing transformation as we move towards becoming a pure electric car maker by 2030.”

Read Also: Volvo’s New Gothenburg Battery Plant Will Be Powered By Renewable Energy

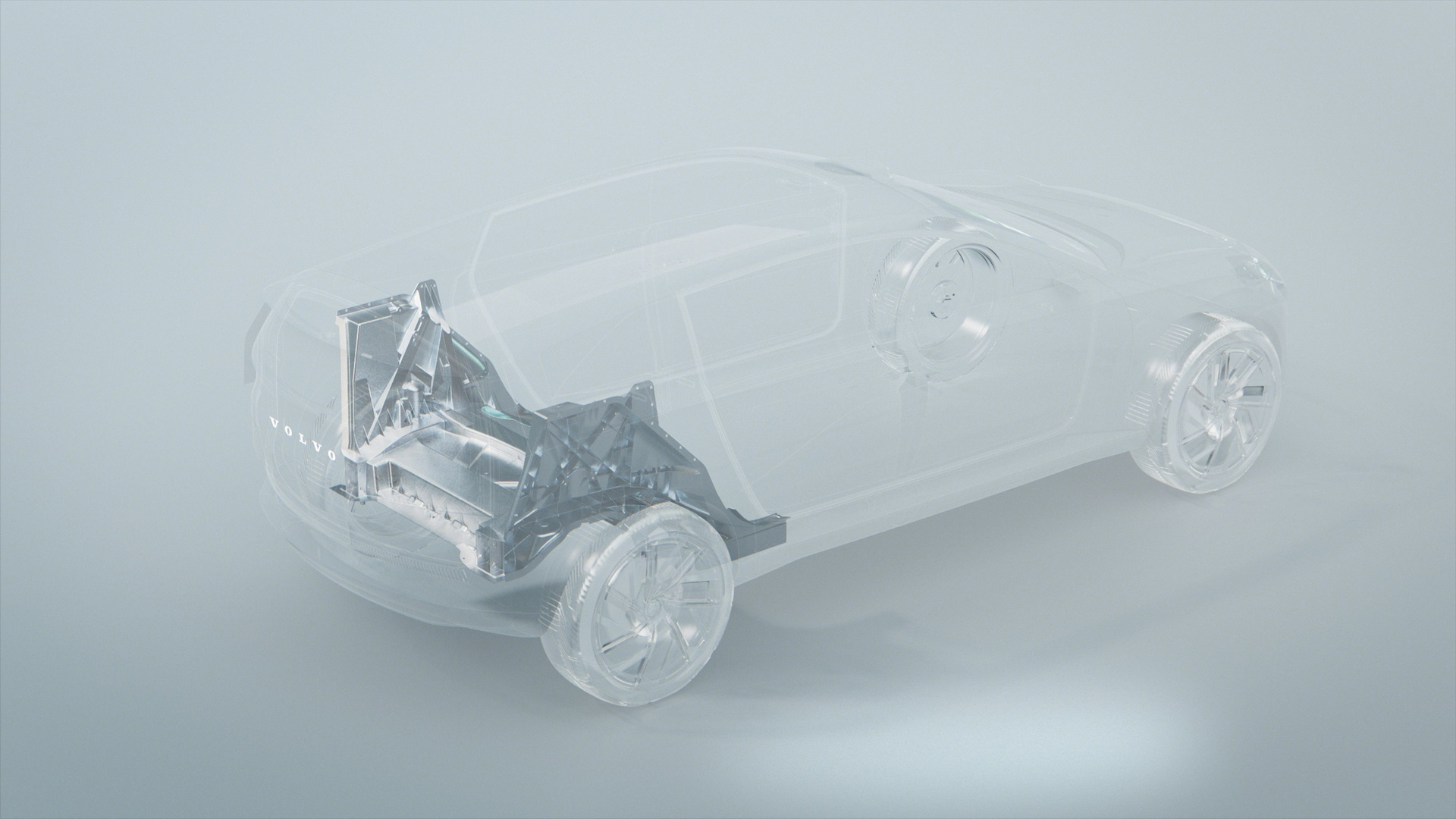

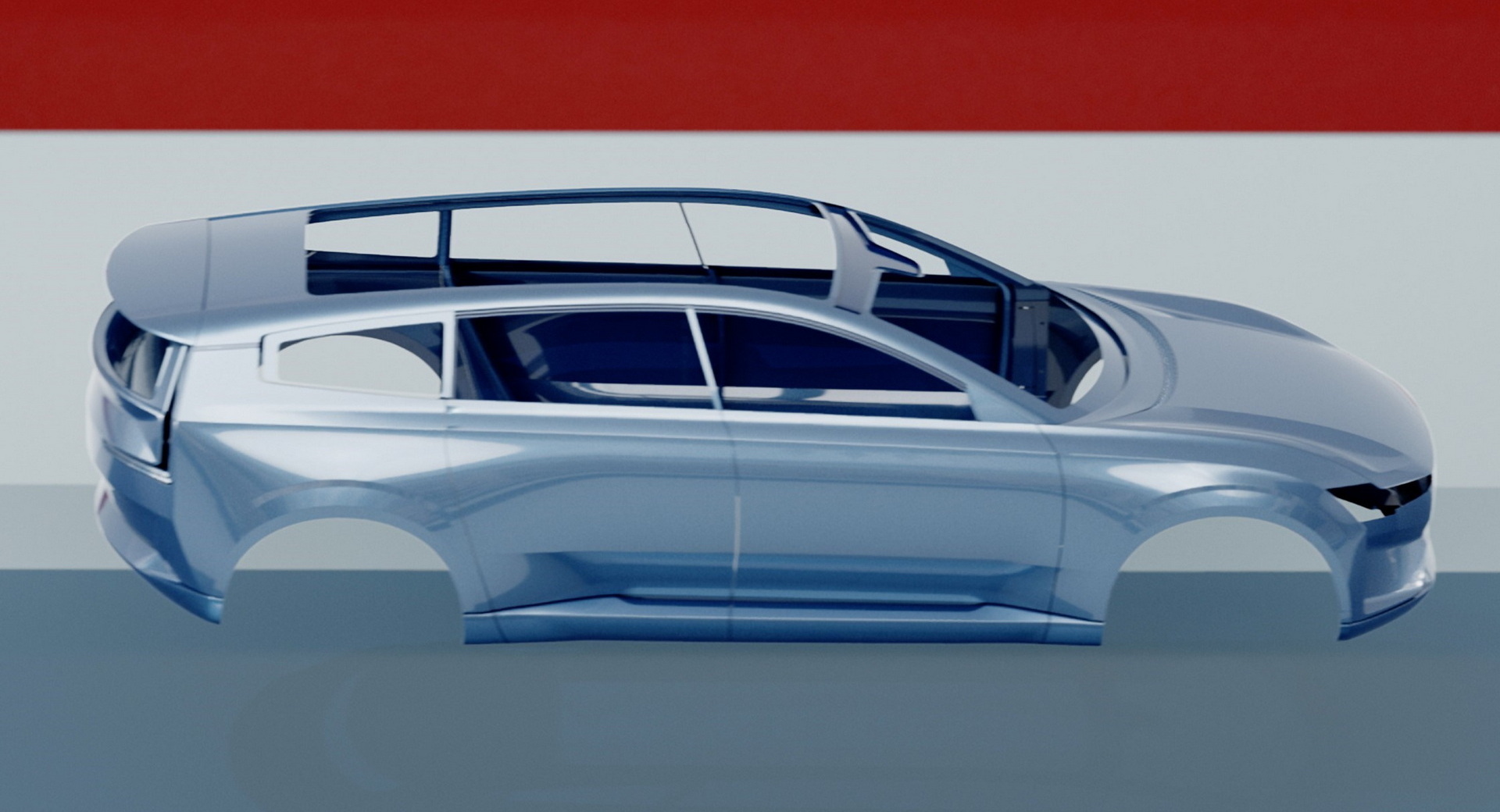

The introduction of mega casting to the site is the most exciting element of the plant update, according to Volvo, as it will allow the manufacturer to cast major parts of the floor structure of its upcoming vehicles out of a single piece of aluminum. That improves the energy efficiency of the parts’ production and lowers their weight, which allows electric vehicles to go farther. It also simplifies the manufacturing process, which saves money.

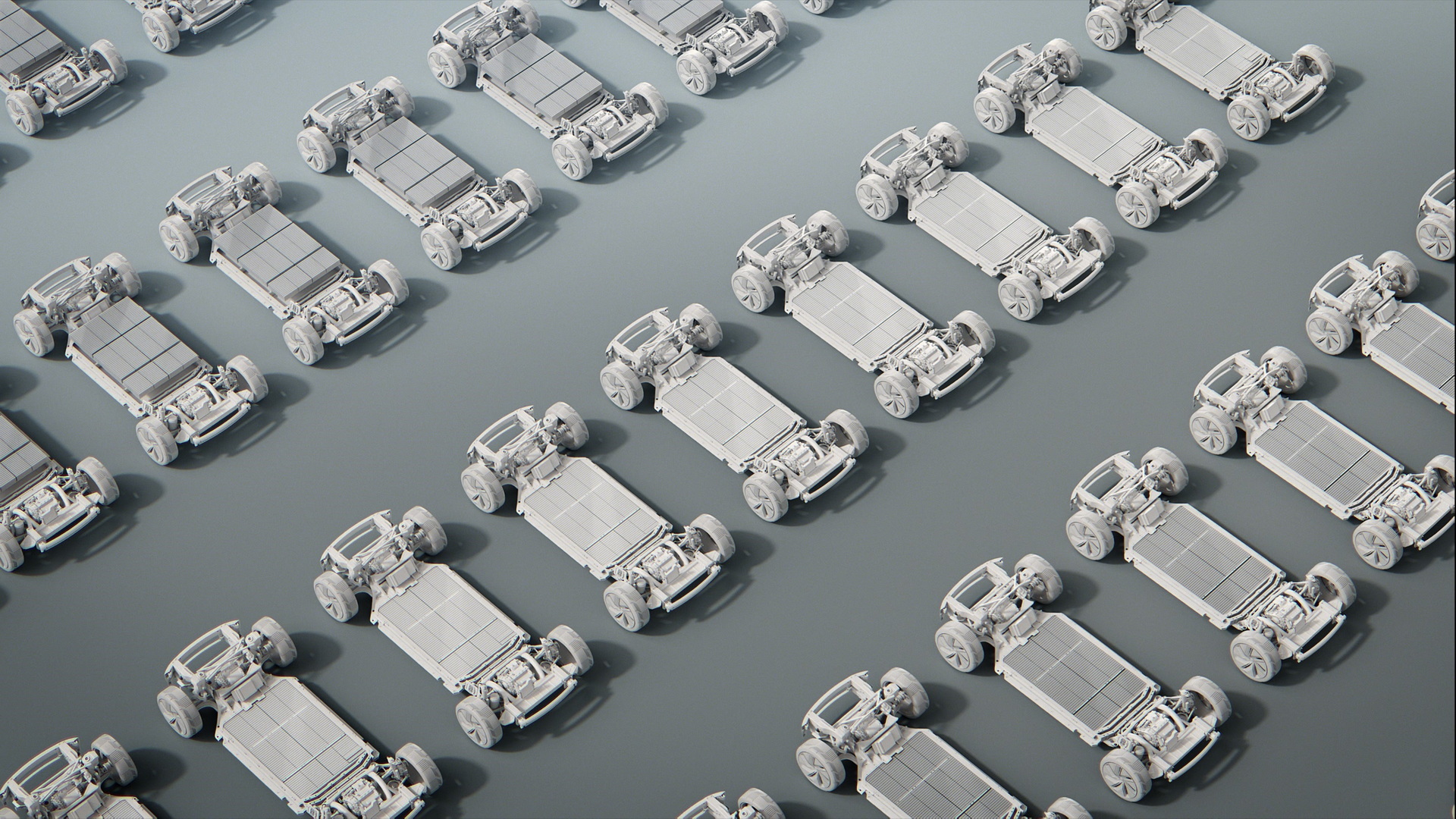

The floors will then be integrated with battery cells in another new section of the plant. The cells, meanwhile, will be manufactured in Gothenburg at a new plant that Volvo announced last week.

“Today is a great day for the Torslanda plant as we are making it fit for the future with this investment package,” said Javier Varela, head of engineering and operations at Volvo Cars. “Our future as a company is all-electric and that requires a variety of upgrades across the plant, to ensure that Torslanda can continue to build premium electric cars of the highest quality.”

The plant, which opened in 1964, has an annual production capacity of 300,000 vehicles. Volvo has not said when this work will be completed.