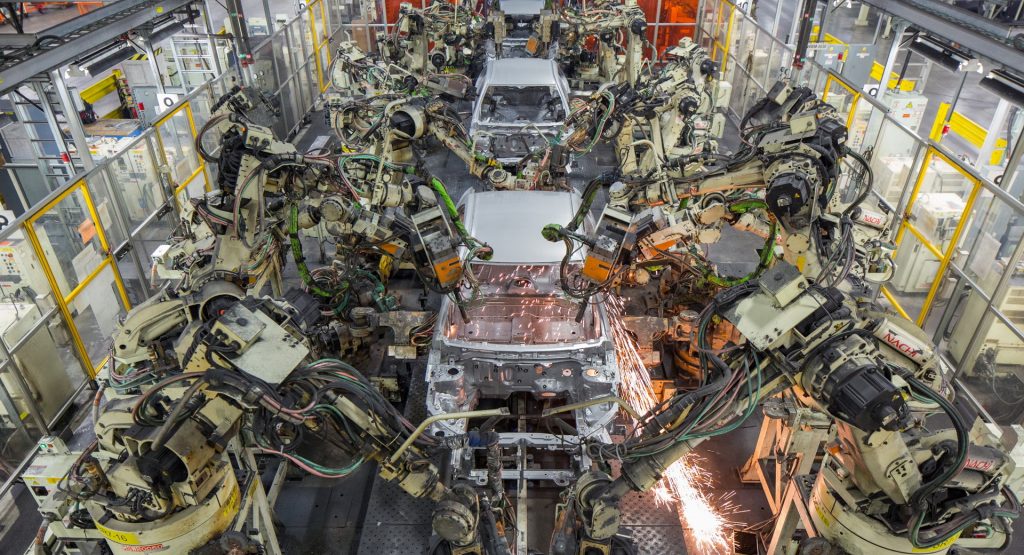

Toyota said Wednesday that it would be reducing production in Japan between April and June to ease the strain on suppliers, many of whom are struggling with shortages of parts, including semiconductor chips.

The automaker plans to slow production from previously announced levels by 20 percent in April, by about 10 percent in May, and by about five percent in June, a spokesperson told Reuters.

The plan is intended to take some of the burden off its suppliers, which have had to deal with a number of changes to production plans as a result of diverse shortages. The effort, Toyota said, is being made in an effort to give suppliers as much lead time as possible by giving them information as early as possible.

Read Also: Toyota Looking To Make Up For Lost Production As COVID-Hit Suppliers Recover

The “intentional cooling off” period is also being made in an effort to make safety and quality Toyota’s highest priorities. Akio Toyoda, the automaker’s president, said in a meeting with union members that supplies would be “exhausted” unless a sound plan was put in place.

Toyota said that production for Q2 will still be high, though, because its previous plans had incorporated the need to make up for lost production from earlier. The automaker plans to produce 11 million vehicles in 2022, as long as chip supplies hold out.

That, though, may be complicated by Russia’s unprovoked attack in Ukraine. The latter produces around 70 percent of the world’s supply of neon, a crucial gas for the lasers that are used in the manufacture of semiconductor chips. Although most chipmakers were stockpiling neon in preparation for Moscow’s actions, a prolonged invasion could lead to another chip shortage.