Tata Group is looking to venture into the worlds of semiconductor and EV battery manufacturing.

The Indian conglomerate’s plans come as the country’s prime minister, Narendra Modi, looks to establish India as a leader in semiconductor production in a bid to reduce its reliance on imports from other countries.

Speaking with Bloomberg, N. Chandrasekaran, the chairman of Tata Group’s main holding company, Tata Sons Pvt, announced the company’s plans. Tata Motors Passenger Vehicles managing director Shailesh Chandra added that recent coronavirus-related lockdowns in China have worsened the supply of semiconductors.

Read More: Tata Avinya Concept Blurs Lines Between Minivans And Hatchbacks, Production EV Coming By 2025

Chandra acknowledged that Tata Motors is finding alternatives to chips and purchasing them from the open market in its bid to push forward with production. Despite these attempts, Tata expects the shortages to continue for at least the next six months and believes the fourth quarter could be more uncertain than the previous year.

Tata also said that the chip shortage is more “acute” in electric vehicles than ICE models, noting that customers will have to wait as long as six months for some of its EVs compared with four months for some of its ICE models.

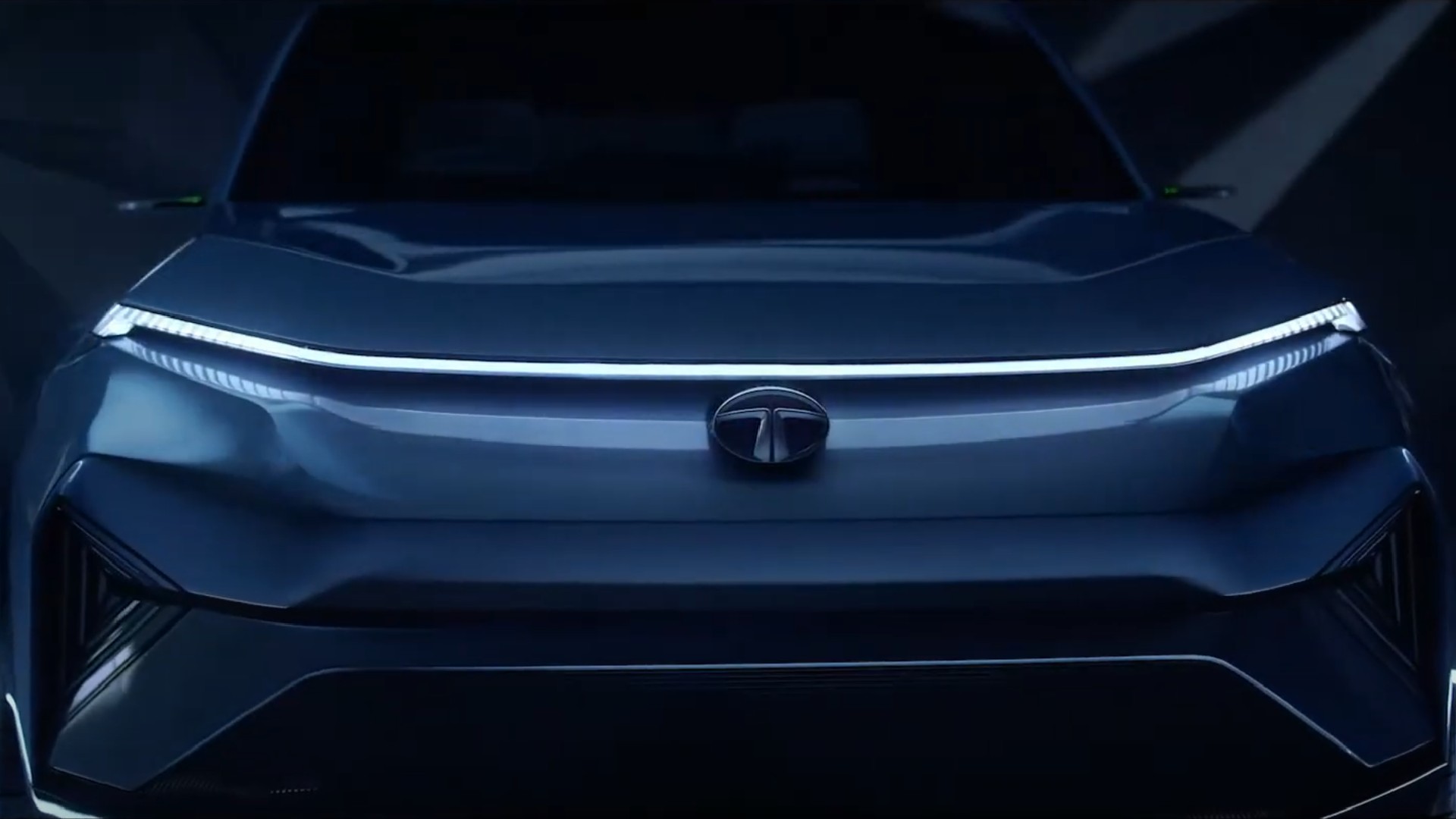

The Indian car manufacturer announced plans to produce its first-ever ground-up EV in 2025 just a few days ago. This vehicle has been previewed with the striking Avinya concept which borrows design elements from SUVs, minivans, and premium hatchbacks, combining them into a silhouette much like a low-slung minivan. It is quite a radical-looking thing and while we don’t yet know how similar the production model will look, Tata has confirmed it will use its new Gen 3 platform and should have a range of at least 311 miles (500 km).