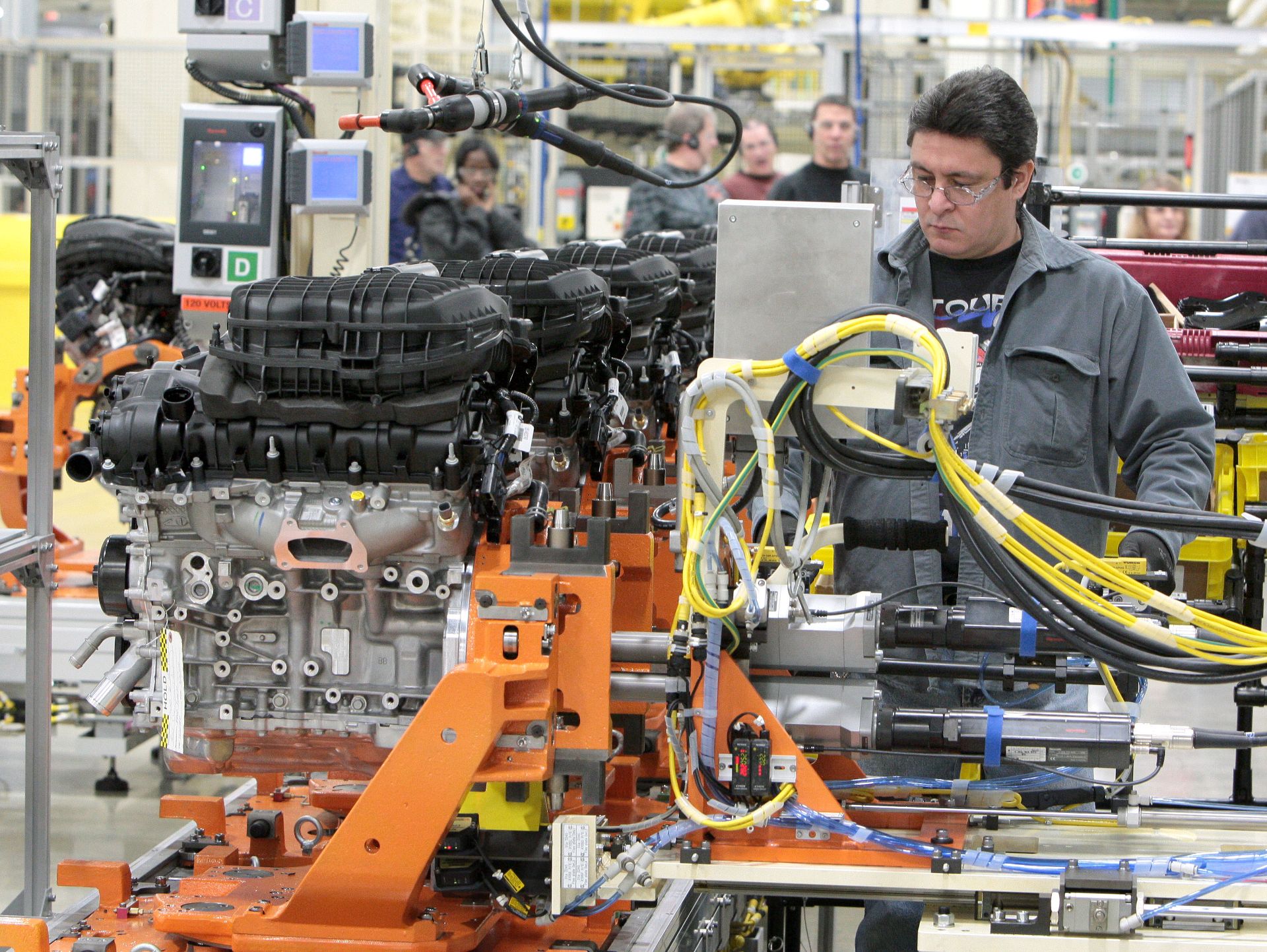

Stellantis announced a $24.7 investment for the engine complex in Trenton, Michigan, where the V6 Pentastar engine is made. Changes in the facility include retooling for the production of an upgraded engine variant, while one of the production lines will be decommissioned.

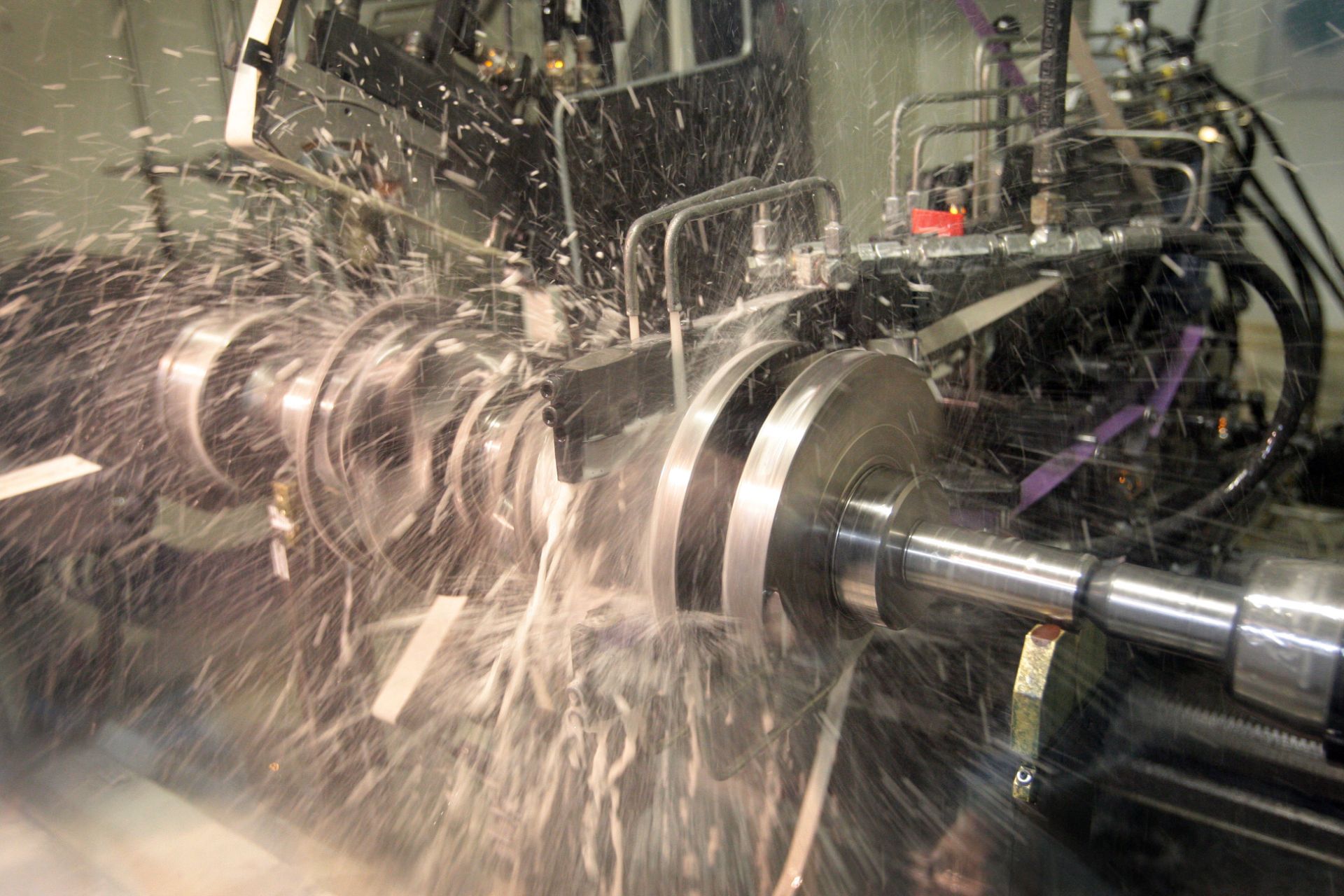

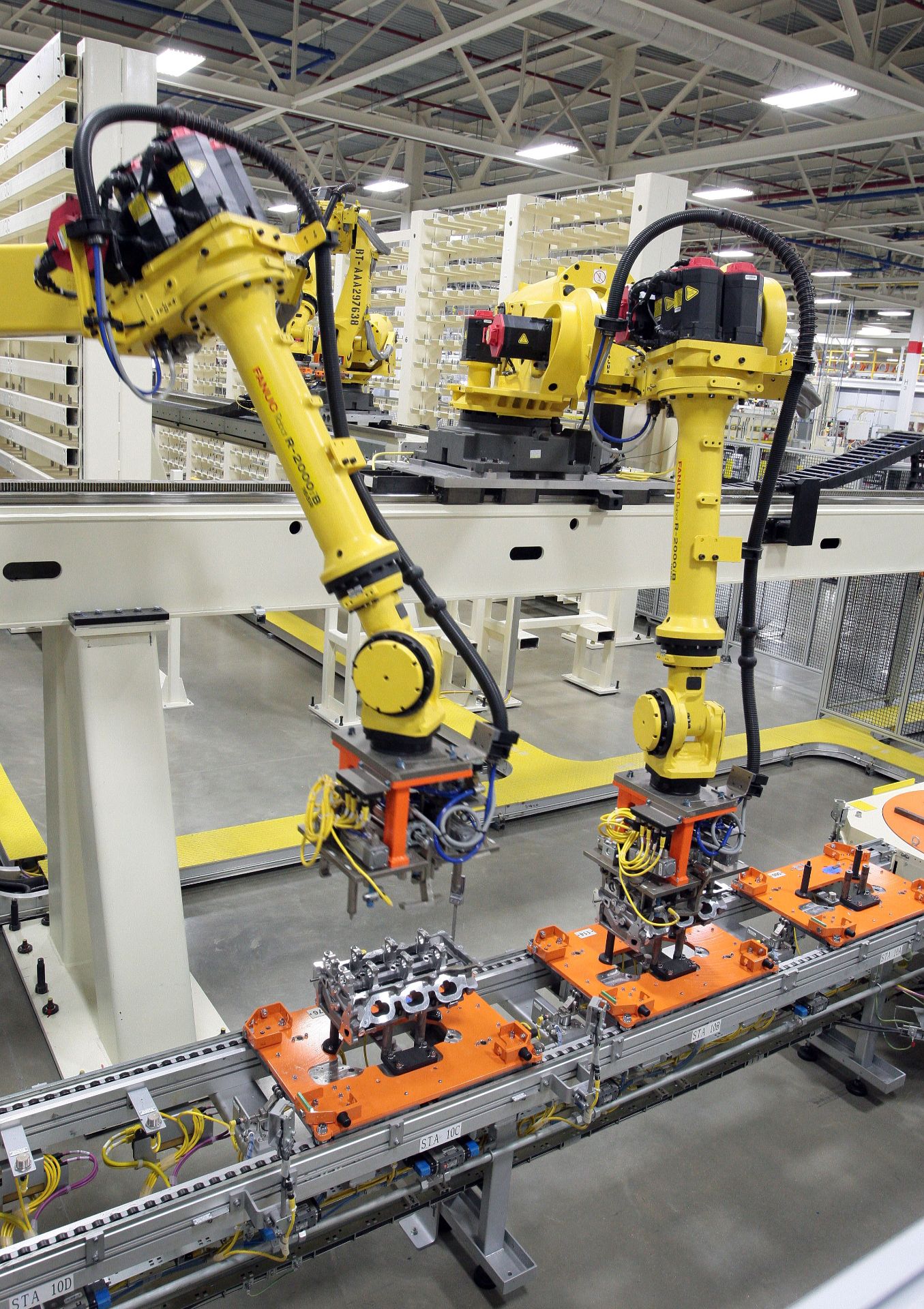

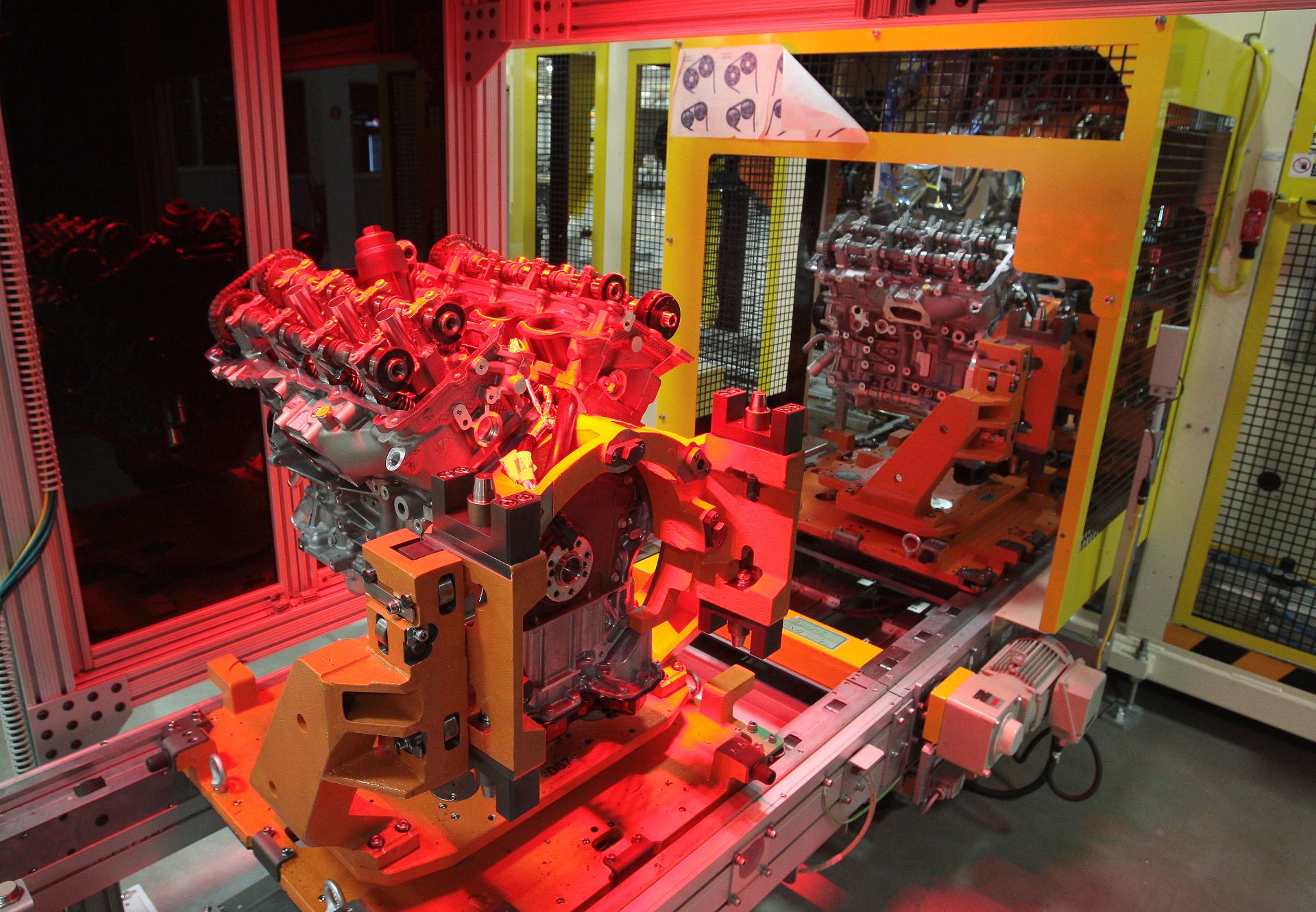

The factory in Trenton comprises two facilities. As part of the investment, the south plant will benefit from retooling. Thus, it will be converted into a flexible engine line that will be able to produce two different variations of the 3.6-liter Pentastar V6, including the upgraded mill that will arrive next year.

Read Also: Car Market Might Implode If EV Prices Don’t Come Down, Warns Stellantis

On the other hand, the existing production line at the north plant will be decommissioned by the end of 2022, with the building being repurposed for warehousing and other non-manufacturing opportunities as noted by Stellantis.

The engine complex in Trenton, Michigan currently employs 1,322 people but the company didn’t mention how many jobs will be affected by the changes. The decommissioned line will likely result in job cuts, although the union is currently in talks with Stellantis about moving workers to other positions, possibly related to EV manufacturing.

The Pentastar line of engines was introduced in 2011. An improved version followed in 2016 with more torque and better fuel efficiency. The V6 which has been used by Chrysler, Jeep, Dodge, and Ram will continue to be produced through 2023 when it will receive a new upgrade. According to Stellantis, the upgraded Pentastar will arrive by the end of the first quarter of 2023.

Stellantis’ Dare Forward 2030 electrification plan which was announced last March wants fully electric vehicles to account for 50 percent of sales in the US by 2030, and 100 percent of sales by 2038. Electrification will move faster in Europe, where all Stellantis brands will be EV-only by 2030.