Bentley announced the start of production of the new Bentayga EWB, the brand’s new flagship model, with the introduction of new hand-craftmanship processes. Each model takes more than 132 hours to produce from skilled craftspeople at the Crewe factory, with the available trim combinations being a staggering 24 billion – yes, billion.

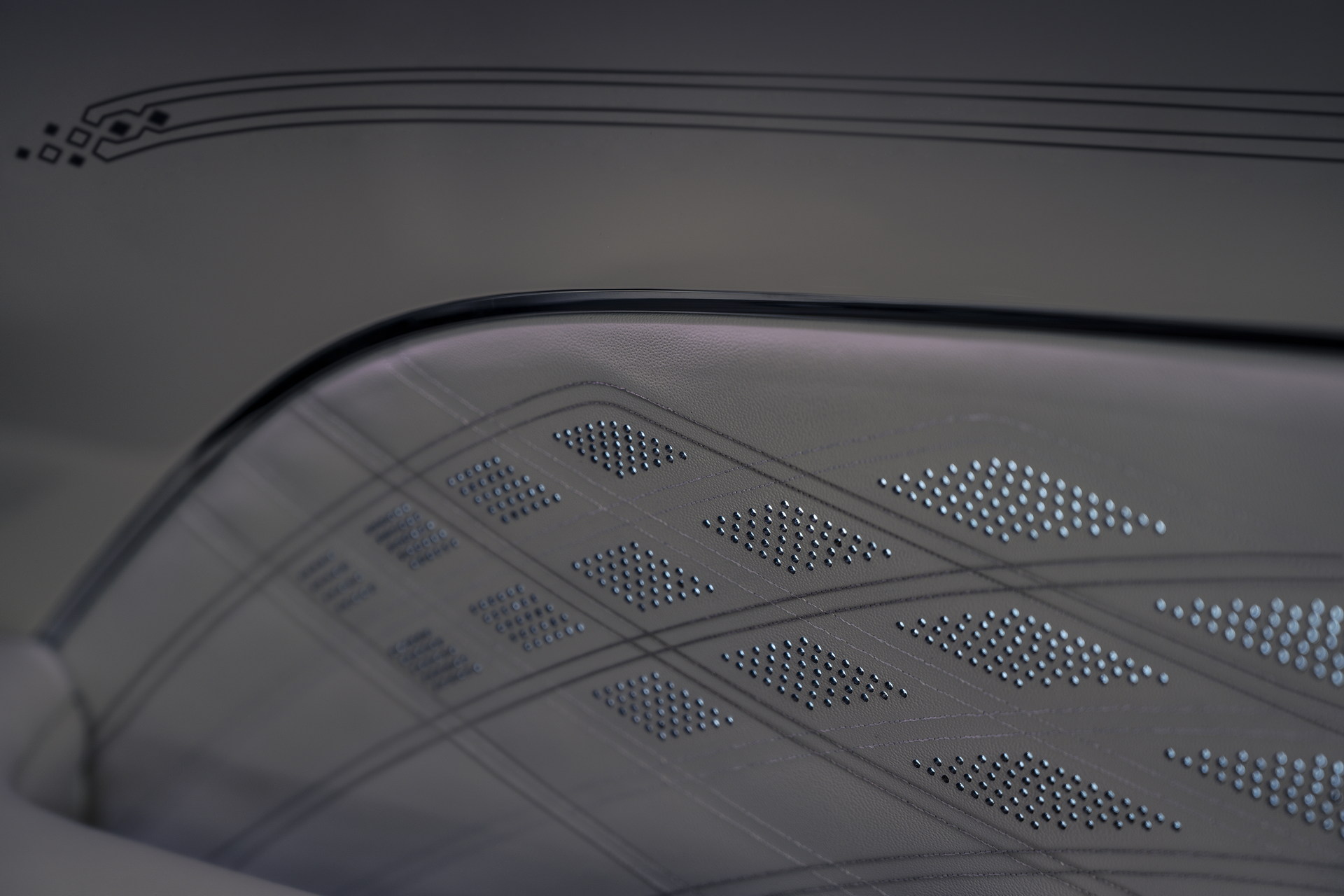

Bentley says that the new longer Bentayga has the most accentuated and softest lofted diamond quilting on the seats and interior trim from all of its models. The perforated leather has digitally positioned 1mm holes, made with the help of a specialized embroidery machine and a smaller micro-stitch.

See Also: Bentley Details Bentayga EWB’s Optional Rear Seats, Says They Are “The Most Advanced Car Seats Ever”

The tiny 1mm holes on the door panels are emitting light thanks to 68 LEDs which are cleverly positioned underneath the leather upholstery. This type of ambient lighting is called “Bentley Diamond Illumination”, with the user being able to change its color and intensity through the infotainment system.

The fine leather is joined by a wide choice of veneers and open-pore wood, with optional 0.07 mm thick metal overlays. The level of attention in the production of the Bentayga EWB is evident from the fact that more than 10 hours are needed for applying the wood set inside the cabin, where tolerances are measured in tenths of mm.

The Bentley Bentayga EWB will make its UK public debut at the Southampton International Boat Show in September, with the first deliveries following shortly.