If you’ve noticed a lot of Toyota research and development articles lately, there’s a good reason for it as the company is celebrating 50 years in Michigan.

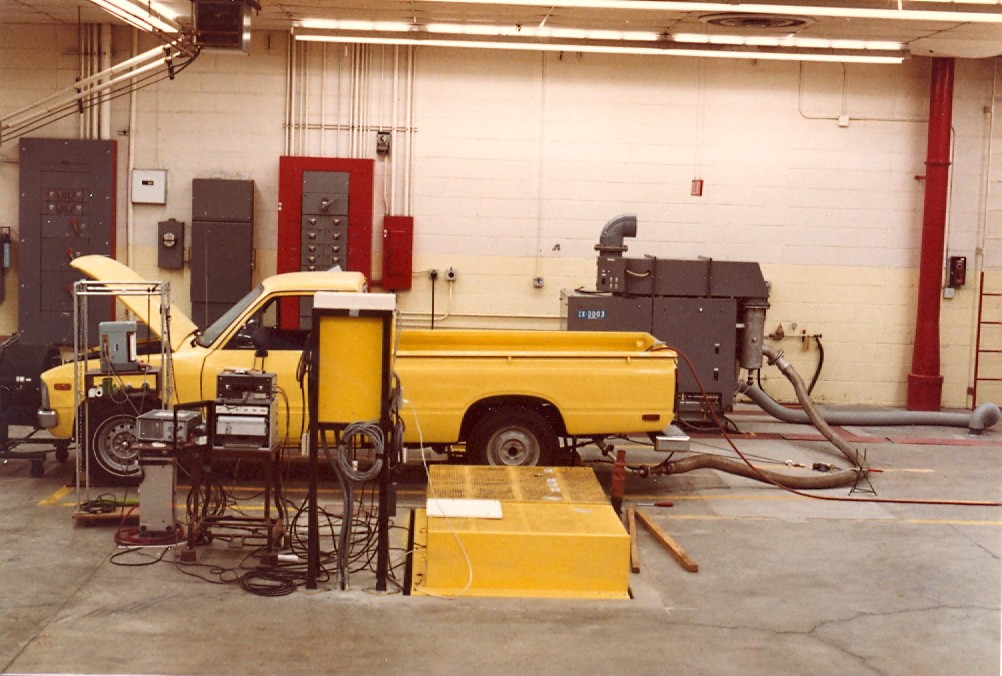

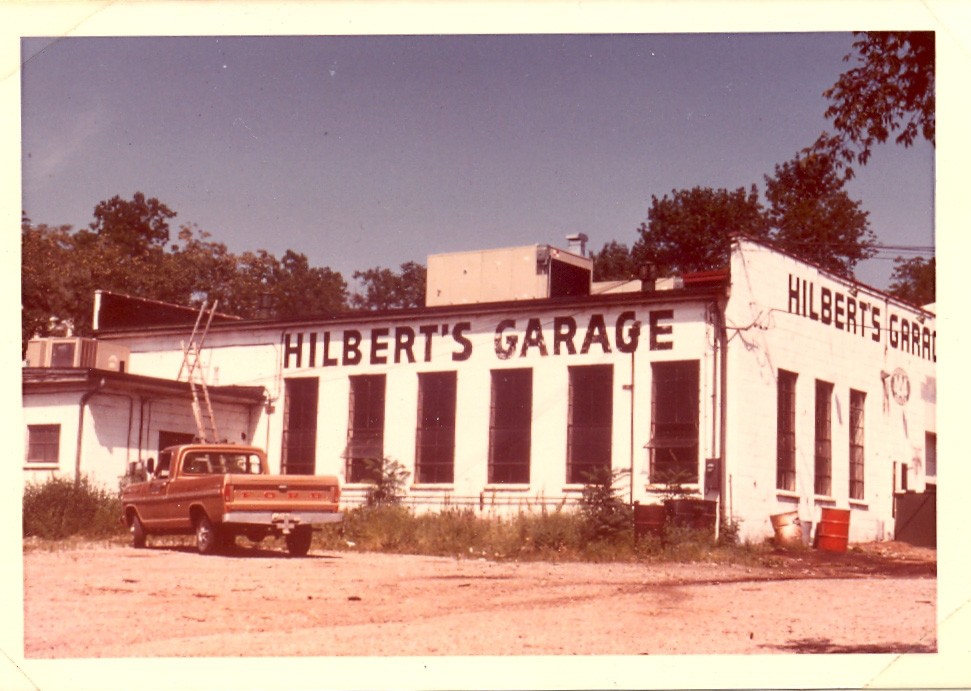

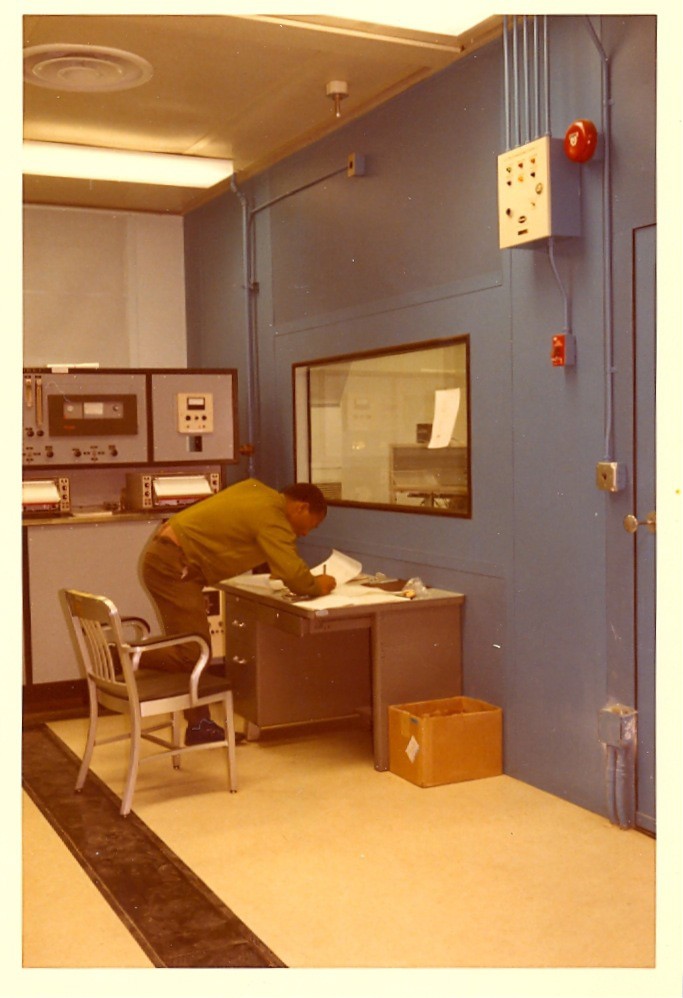

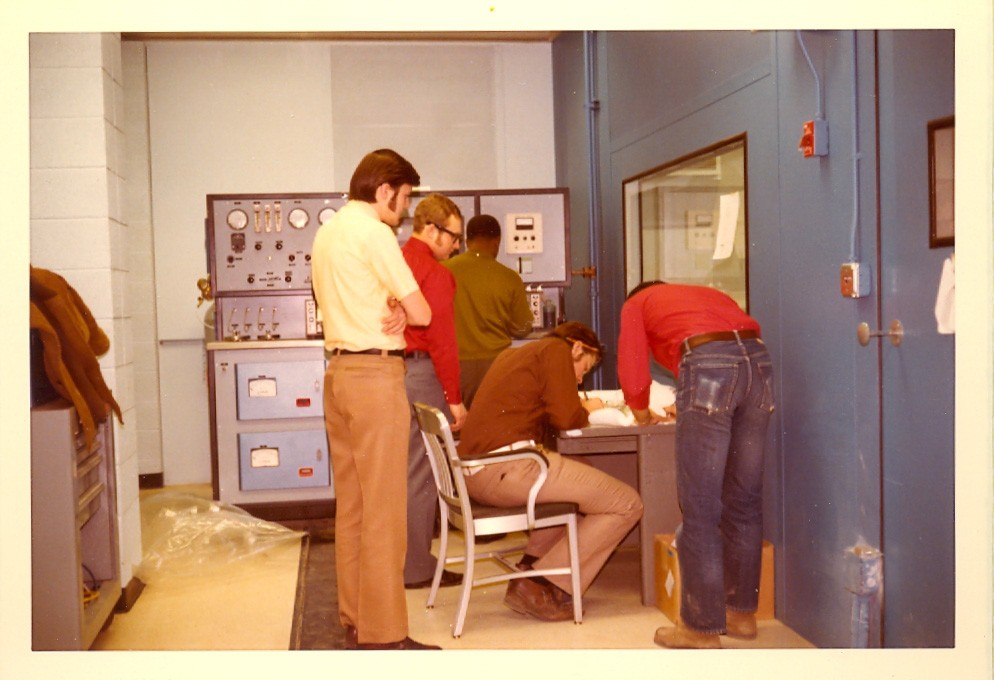

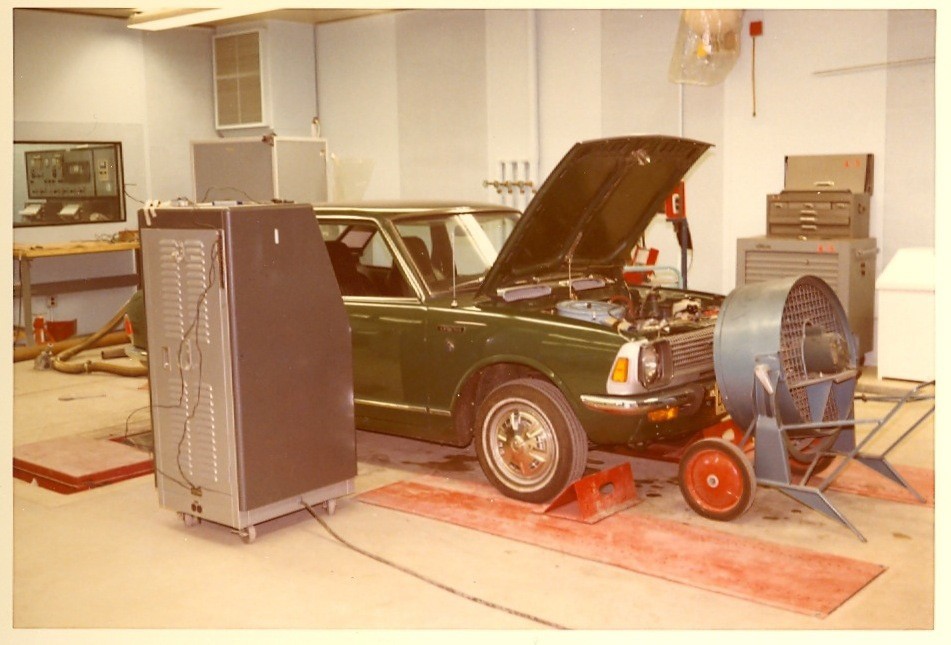

The journey started in 1972, when Toyota needed a place to perform vehicle emission tests near the Environmental Protection Agency office in Michigan. As a result, it bought Hilbert’s Garage in nearby Ann Arbor.

This started a long journey and five years later, the Toyota Technical Center (now known as Toyota Motor North America Research & Development) was established in Southfield to become home to North American research and development operations. While the names and locations would change over the decades, Kazuhiko Miyadera, who led engineering at TMNA R&D from 1986-1991, explained it best as he said “The U.S. is an especially important market for Toyota” and “to sell Toyota vehicles in the U.S., Toyota had to become American citizens.”

Also Watch: Toyota Plays Follow The Leader With Autonomous, Hitchless Towing Tech

While Americans had a limited role in the early years, their responsibilities would grow over the decades and now TMNA R&D is tasked with product development, engineering design, vehicle evaluation, prototype builds, powertrain, advanced research, and purchasing. They’ve also played a key role in developing US-focused models including the Tundra, Tacoma, and Sequoia.

Today, Michigan is home to Toyota’s largest research and development facility outside of Japan. It employs more than 1,800 people that deal with everything from on-site production to testing at Toyota’s only crash test facility outside of Japan.

While that’s just a brief glimpse at Toyota’s history in Michigan, let’s look at some of the projects they’re working on besides autonomous drifting and hitchless towing. We’ll only touch on these briefly, but the Toyota Research Institute is using artificial intelligence to find new catalysts to make fuel cell vehicles more efficient.

Speaking of fuel cells, the company showed a 50 kW fuel cell system that can be used for everything from backup power generation to charging plug-in hybrid and electric vehicles. The company also continues to work on hydrogen-powered semis and recently announced plans to collaborate with the U.S. Department of Energy’s National Renewable Energy Laboratory to build, install, and evaluate a 1 megawatt fuel cell power generation system at the Flatirons Campus in Arvada, Colorado.

Toyota is working on a “rapid BEV product expansion,” although they continue to believe the future needs a variety of powertrains. Officials also revealed the Inflation Reduction Act doesn’t have an immediate impact on their plans, but the company was already looking at increased localization and previously announced plans for a $1.29 billion battery plant in North Carolina.

Speaking of EVs, Toyota sees significant bottlenecks for both lithium and nickel. The Inflation Reduction Act will presumably make this situation even worse due to sourcing requirements to qualify for tax credits.