The Toyota Research Institute announced that it will be partnering with Northwestern University to use the world’s first data factory with the goal of making vehicles greener and more efficient.

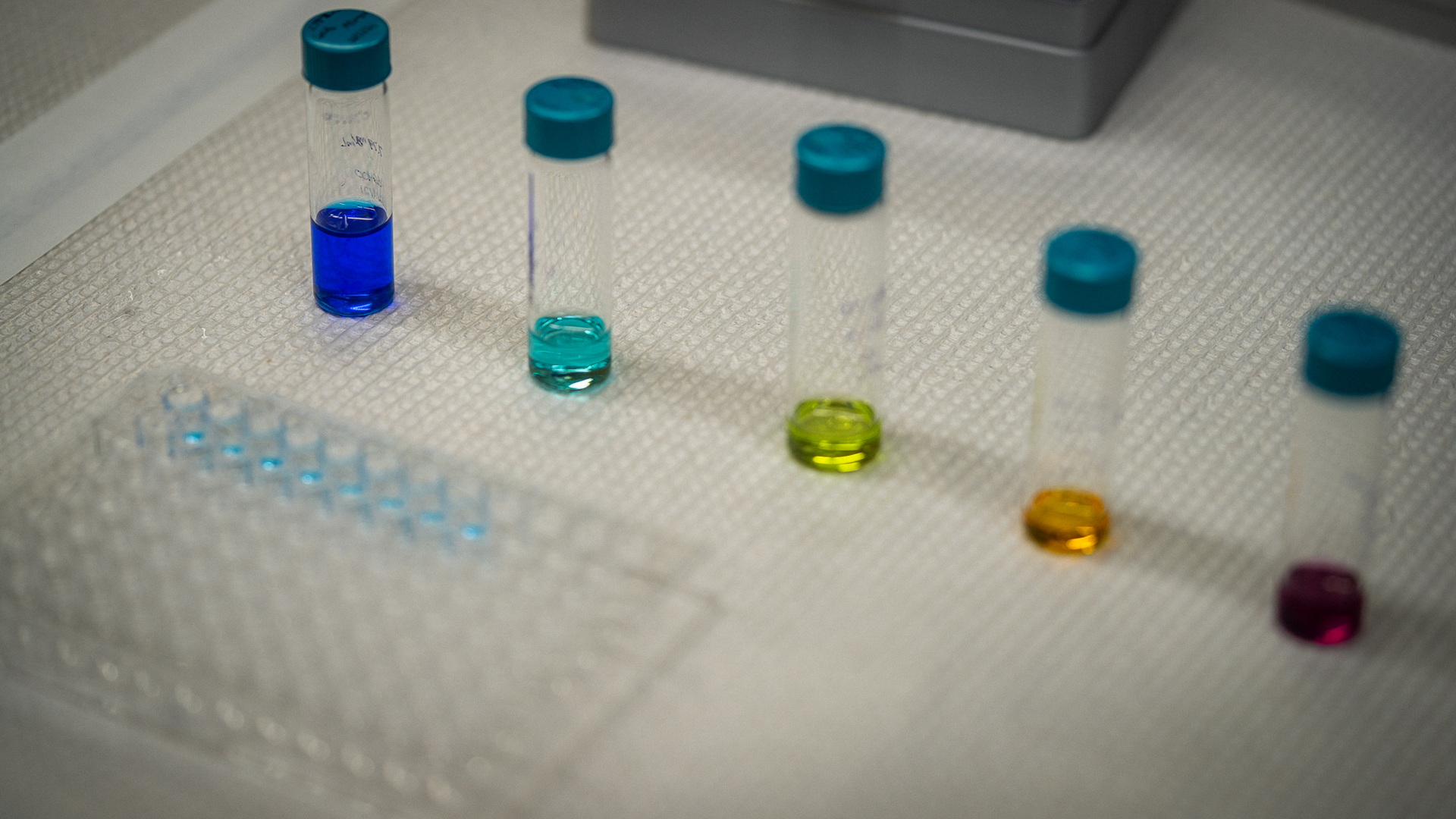

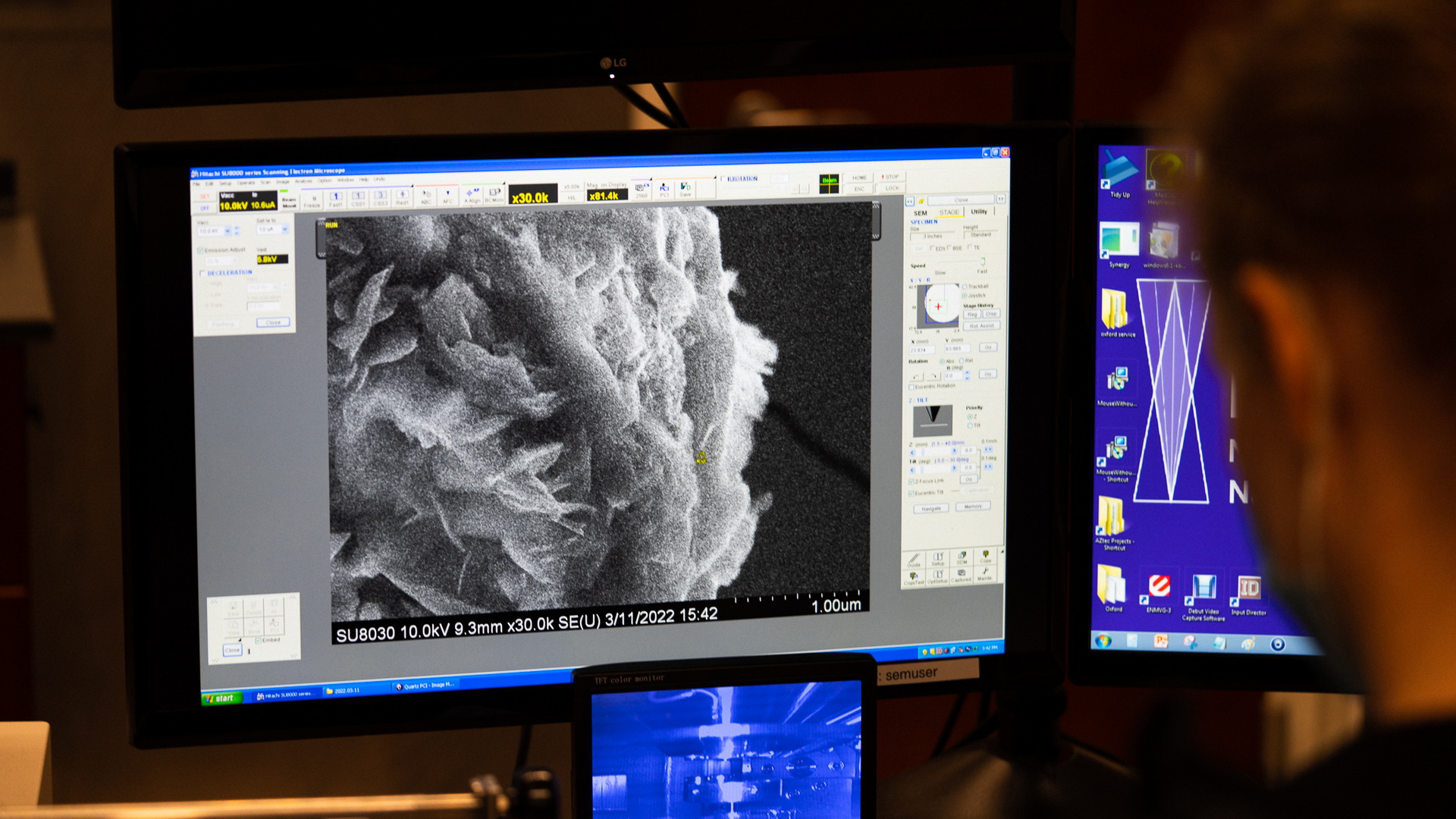

The data factory is a machine learning algorithm that is capable of synthesizing materials at record speeds. The team will use it to look through Northwestern’s new “Megalibraries.” These contain more new inorganic materials than scientists have ever collected and categorized in the past.

Rather than using a trial and error approach to combining materials hoping for something useful, the data factory will work through the data in the megalibraries using AI to search the materials genome to find what will work in a given circumstance. Even with machine learning, prior to this collaboration, Toyota says that AI was trained on lower-quality data sets. It believes, though, that this system can be trained to enable complex algorithms for the rapid and objective discovery of crucial materials for specific needs.

Read Also: Toyota, Suzuki, And Daihatsu To Develop Mini Electric Vans And Fuel Cell Trucks

“This groundbreaking research marks an inflection point in how we discover and develop critical materials,” said Chad Mirkin, director of the International Institute for Nanotechnology and the George B. Rathmann Professor of Chemistry at Northwestern. “Together with TRI, we’re poised to empower the scientific community to find the best materials that can truly power the clean energy transition.”

In this particular case, Toyota is looking for new catalysts to make fuel cell vehicles more efficient. It believes, however, that this method of material scanning will have many applications. Together, they expect to be able to find ways to make hydrogen more cleanly, remove CO2 from the air, and develop high-efficiency solar cells.

“Meeting the growing demand for mobility without emitting carbon is a major challenge,” said Brian Storey, TRI senior director of energy and materials. “Through this partnership with Northwestern, we have significantly reduced the time it takes to test and find new materials that can be used in batteries and fuel cells to decarbonize transportation.”