Mercedes-Benz has started to use the Nvidia Omniverse platform to design and plan future manufacturing and assembly facilities.

The announcement, made at the ongoing Consumer Electronics Show (CES) in Las Vegas, will see the German car manufacturer use Nvidia’s advanced AI and metaverse technologies to create smarter and more efficient vehicle manufacturing.

Read: Hyundai, Kia, Genesis, And Polestar Team Up With NVIDIA To Bring Cloud-Based Gaming To Cars

The two companies are currently establishing a ‘digital first’ planning process for its plant in Rastatt, Germany which currently handles production of the A-Class, B-Class, GLA, and the all-electric EQA and will soon start manufacturing Mercedes-Benz’s dedicated platform for future electric vehicles. The planning process will not impact current production at the site and will later be rolled out to other parts of the global Mercedes-Benz production network.

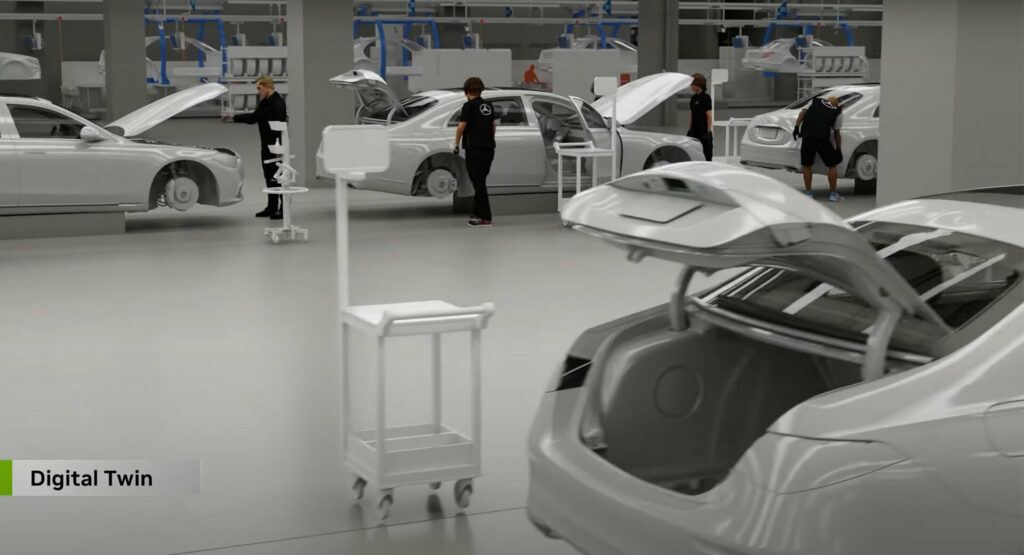

Nvidia’s Omniverse system is an advanced 3D development platform that allows enterprises and institutions to build and operate digital twins of pre-existing factories for industrial and scientific use cases. Mercedes-Benz planners will be able to easily access the digital twin of its Rastatt factory and review and optimize it as necessary. These changes can be quickly and easily evaluated and validated in the virtual world and then implemented in the real world “to ensure maximum efficiency and ergonomics for factory workers.”

The German car manufacturer will also be able to synchronize plant locations anywhere in the world by connecting Omniverse with its in-house MO360 Data Platform. This not only streamlines operations across the automaker’s global production network but also enables over-the-air software updates to manufacturing equipment.