Nissan has unveiled a new approach to electrified powertrain development which it says will allow it to achieve price parity between its hybrid vehicles and ICE vehicles by around 2026.

Under Nissan’s X-in-1 approach, Nissan will share core powertrain components between its EV and e-Power models and modularize them. This will result in a 30 percent reduction in development and manufacturing costs between 2019 and 2026. Not only will it allow hybrids to achieve price parity with ICEs by around 2026 but it will also allow Nissan to achieve price parity between full EVs and ICEs in 2030.

Read: Nissan Forgot To Bolt Down Some Ariya Steering Wheels

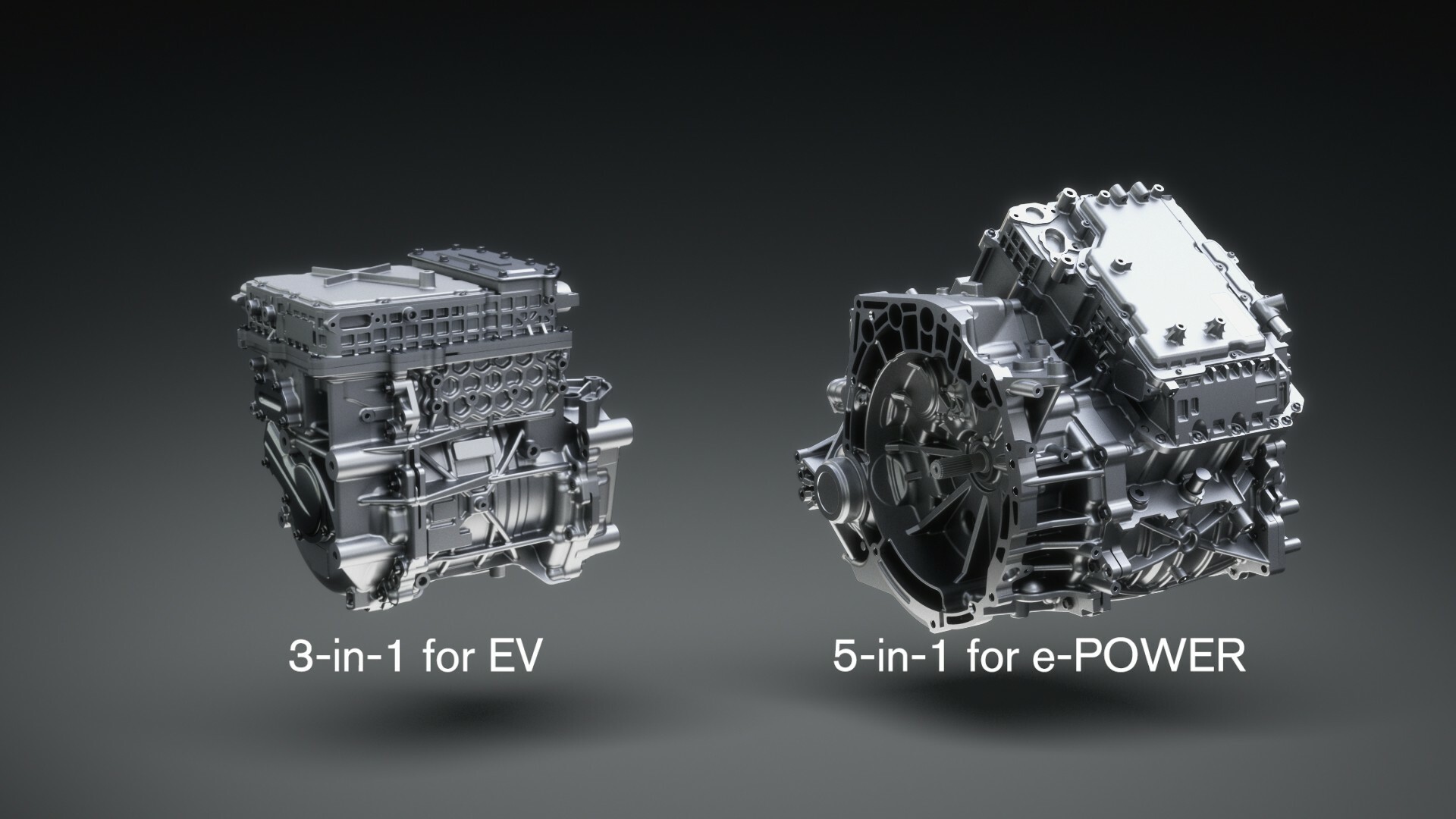

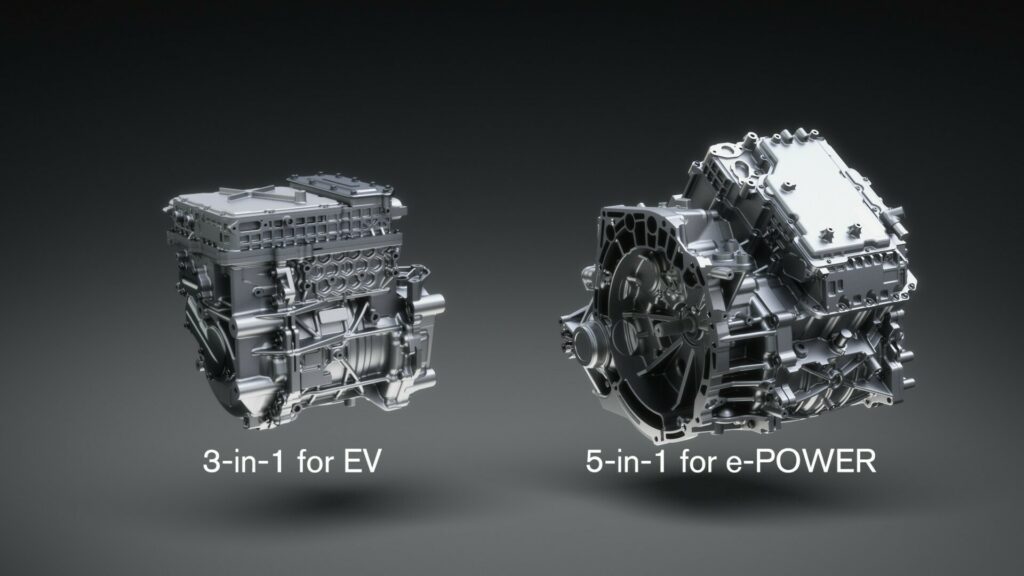

Two different powertrains will be developed. The first will be for its EVs that adopt a 3-in-1 module, integrating the motor, inverter, and reducer into a single casing. Meanwhile, the carmaker’s e-Power hybrid models will adopt a 5-in-1 setup that combines the motor, inverter, generator, reducer, and increaser.

The reducer used by Nissan slows the revolutions per minute of the electric motor to a speed that will turn the axle and wheels, while the increaser speeds up the revolutions of the e-Power’s combustion engine to spin the generator that recharges the system’s battery.

Nissan notes that packing these components into a single unit doesn’t just improve production efficiencies and reduces powertrain costs but also results in size and weight reductions that improve driving performance and minimize noise and vibration. The carmaker will also adopt a newly developed electric motor that reduces the use of heavy rare earth elements to 1 percent or less of magnet weight.

“We make the most of our expertise and know-how from our more-than-a-decade long development and production of electrified technologies,” noted senior vice president of Nissan, Toshihiro Hirai. “Through our innovations in electrified powertrain development, we’ll continue to create new value for customers and deliver 100% motor-driven vehicles – EVs and e-POWER – as widely as possible.”