Since 2021, Toyota has been working with the Fukushima Prefecture in Japan to develop hydrogen technologies to power its plant there. Those efforts, it says, will help it use automotive technology to decarbonize its production facilities.

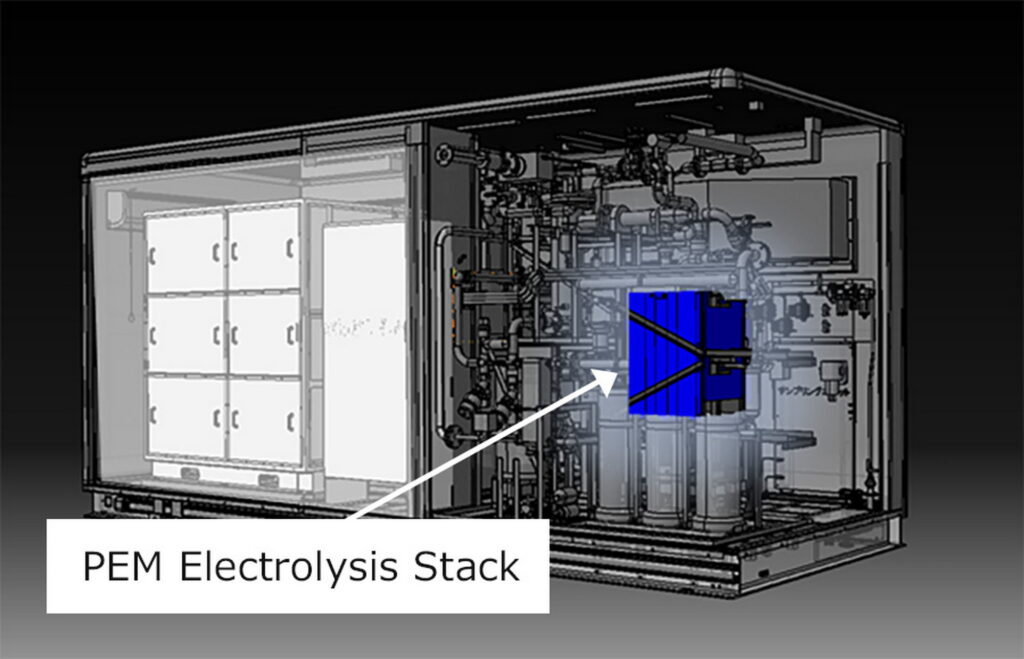

The automaker recently developed new electrolysis equipment that it says produces hydrogen from water, using the fuel cell stack, as well as other associated technology, from the Mirai. This month, it plans to put the technology into use at a DENSO Fukushima Corporation plant.

Using technology that it developed for the Mirai and the Sora FC bus, Toyota’s generators use proton exchange membrane cells that it claims are highly reliable because of the mass production of those vehicles.

Read: BMW’s First Series-Production Hydrogen Model Set To Arrive By 2030

The new equipment will also use titanium stack separators to improve the reliability of the electrolysis equipment, a trick it learned on the first-generation Mirai. The material is used because of its corrosion resistance, which helps generator performance remain stable after more than 80,000 hours of operation.

In all, the generators’ fuel cell stacks will share 90 percent of their components with Toyota’s fuel cell electric vehicles. That, it says, will allow it to mass produce the parts, reducing costs for both its generators and vehicles.

Ultimately, Toyota plans to use the Fukushima plant as a proof of concept to promote the technology’s widespread adoption. A big believer in hydrogen, Toyota also announced recently that it has run a racecar on liquid hydrogen for the first time ever, and plans to compete with it in the 2023 season of the Super Taikyu racing series.

Far from the only automaker investigating hydrogen technology, Toyota’s Japanese rival, Honda, also recently announced that it has put a hydrogen generator into use. It says that the emissions-free technology is being used by its California data center as a power backup, replacing the polluting diesel generator that was there before.