Following a deal with Unifor in 2020, Ford has officially laid out plans to turn Oakville Assembly into a “Canadian hub of electric vehicle manufacturing.”

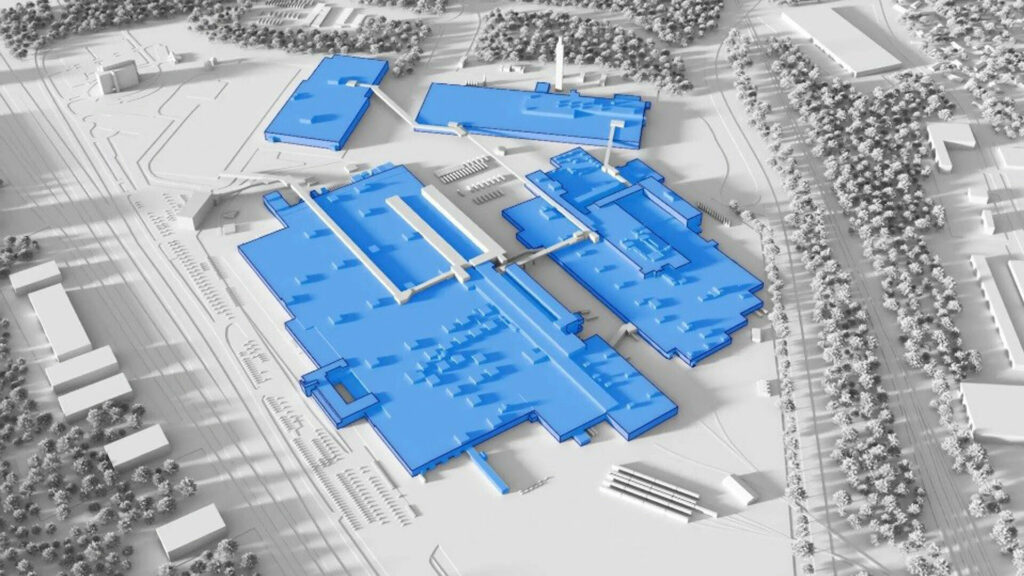

As part of the effort, Ford is investing $1.3 billion ($1.8 billion CAD) to transform Oakville Assembly into the new Oakville Electric Vehicle Complex. The 487 acre site is being completely reimagined as it currently consists of three body shops, one paint building, and one assembly building. The new complex will be far more streamlined and feature four main buildings including one each for body, paint, and assembly.

The fourth and final building will be an all-new 407,000 square foot battery plant, which will use components sourced from the BlueOval SK Battery Park in Kentucky. Ford said workers will “utilize cells and arrays” from the U.S. plant to assemble battery packs in Canada.

More: Ford Claims Title Of ‘Most American’ Automaker With Most Hourly Workers And Cars Built In U.S

Ford will begin to retool and modernize Oakville in the second quarter of 2024 as part of their effort to “prepare for production of next-generation electric vehicles beginning in 2025.” The company went on to say this “marks the first time a full-line automaker has announced plans to produce passenger EVs in Canada for the North American market.”

Ford declined to say what will be built at the plant, but former Unifor National President Jerry Dias had said the company would build “five models of electric vehicles.” The first was slated to arrive in 2025, while the last would come off the line in 2028.

However, more recent reports have suggested Oakville might only build two electric vehicles. These are rumored to include electric versions of the Ford Explorer and Lincoln Aviator, and it’s believed they could prove popular enough to keep the plant busy with just two products.

Regardless of what will be built at Oakville, Ford CEO Jim Farley remarked “Canada and the Oakville complex will play a vital role in our Ford+ transformation. It will be a modern, super-efficient, vertically integrated site for battery and vehicle assembly.” He added, “I’m most excited for the world to see the incredible next-generation electric and fully digitally connected vehicles produced in Oakville.”