Stellantis wants to reduce the weight of its electric vehicle battery packs by 50% before the end of the decade. As it stands, the conglomerate believes that battery packs are too heavy and it is looking to cut weight with advanced battery technologies and the more efficient packaging of cells.

A key move made by Stellantis is its investment in Silicon Valley-based Lyten. The company is developing lighter lithium-sulpher batteries that don’t just reduce weight but also use fewer exotic materials than traditional lithium-ion batteries. Stellantis is also exploring the potential of sodium-ion batteries that are already being developed by CATL, and others, and could be much cheaper than traditional packs.

During a recent interview with Autocar at the opening of the company’s Mirafiori battery technology center in Turin, Italy, Stellantis head of engineering and technology Ned Curic noted that current batteries are simply too heavy.

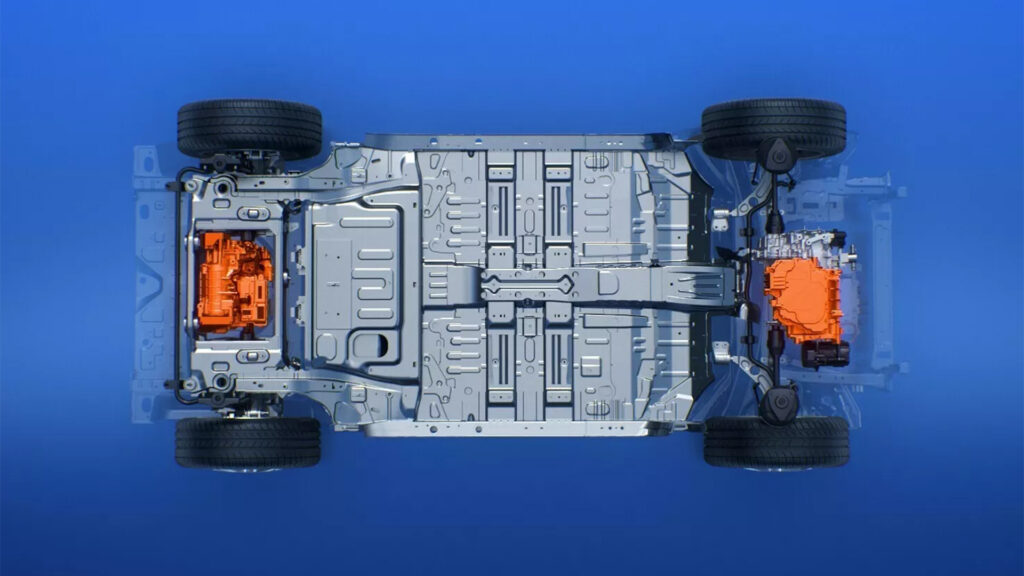

Read: Stellantis Reveals New Battery Design That Makes EV Powertrains Smaller, More Efficient

“The battery today is just too heavy; the vehicle is too heavy. We shouldn’t be going backwards,” he said.

Stellantis has already spent €40 million ($43 million) on the development of its new battery technology center. It can test up to 47 battery packs in parallel through the 32 available climate test chambers. The site will ultimately serve as the point of development and testing for cells and software to be used by EVs from the likes of Alfa Romeo, Citroen, Fiat, Peugeot, and Opel/Vauxhall.

The automotive giant has also partnered with the National Center for Scientific Research in France, as well as Saft, the battery solutions company of TotalEnergies to create a battery pack that neatly integrates the inverter and charger functions within the module, InsideEVs reports.