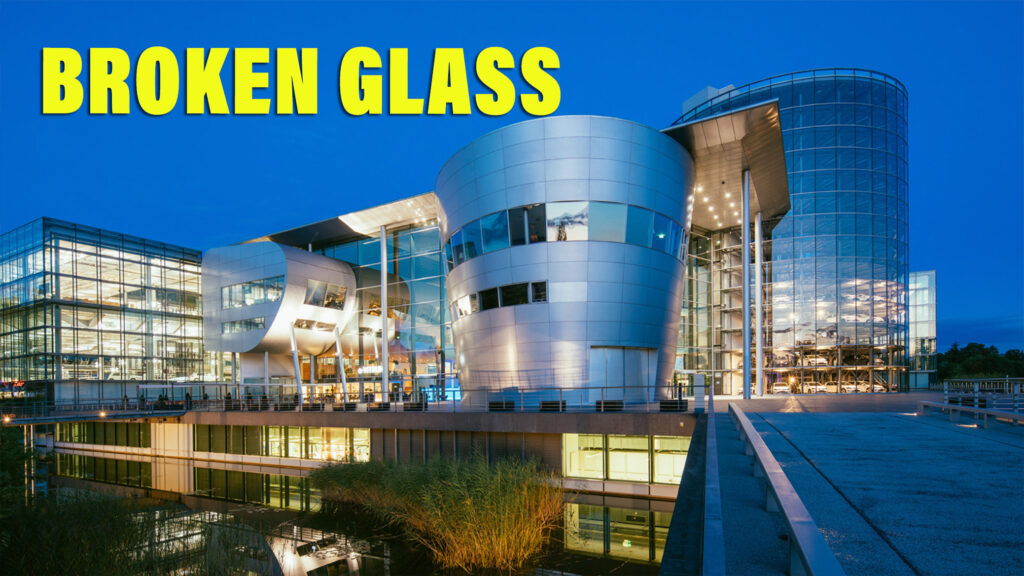

Volkswagen’s Dresden plant isn’t like most car factories. While most plants are anonymous gray boxes with all the visual charm of an Amazon distribution center, the Dresden site is an incredible glass-walled facility that allows viewers to watch cars taking shape.

Nicknamed the “Glaeserne Manufaktur” (transparent factory) as a result, the Dresden plant was opened in 2002 as a production center for VW’s ill-fated Phaeton luxury sedan, and currently produces the ID.3 electric hatchback. But soon the Dresden facility will have another trait setting it apart from other car factories: they’ll be making cars, and it won’t.

VW is planning to end production at the site to help cut costs, according to a report in Germany’s Automobilwoche, although the story – unconfirmed by VW – says the circa-300 workers currently employed at the site will be given other tasks there, rather then being let go.

Related: The Phaeton Was Volkswagen’s Doomed Venture Into The Premium Class

Ending production at the plant could save €20 million ($21 m) per year, a VW source told Bloomberg, which would make a significant dent in the €60-70 million ($64-75 m) annual operating cost of the site. Automobilwoche claims the move is part of Porsche and VW CEO Oliver Blume’s plan to increase VW Group profit by €10 billion ($10.7 bn) by 2026.

While workers at Dresden might not be losing their jobs, some of their brothers at the Zwickau site responsible for EVs like the ID.4 haven’t been so lucky. VW recently announced that it was no longer able to go through with a plan to offer permanent contracts to 269 temporary workers. The automaker blamed tough market conditions, which include increasing competition from Chinese-built EVs and a reduction in demand partly attributed to cuts in government subsidies for EVs and higher interest rates that affect affordability for buyers.

H/T to Automobilwoche via Auto News