- Toyota admits to falsifying safety tests for seven additional models.

- Japan halts production of Toyota minivans due to safety scandal.

- Toyota blames management failures for widespread misconduct.

Toyota has confessed to yet another round of safety testing misconduct, involving seven additional models. This fresh admission piles onto the existing scandal engulfing the Japanese automotive industry, which includes Honda, Mazda, and Suzuki.

Toyota’s troubles are far from over. Following the initial expose of safety testing misconduct, Japan’s Ministry of Land, Infrastructure, Transport and Tourism (MLIT) has uncovered even more irregularities during its ongoing investigation. This latest revelation casts a larger shadow over the automaker and the entire Japanese automotive industry.

More: Toyota, Honda, Mazda, Suzuki Faked Emissions And Safety Tests, Some JDM Sales Halted

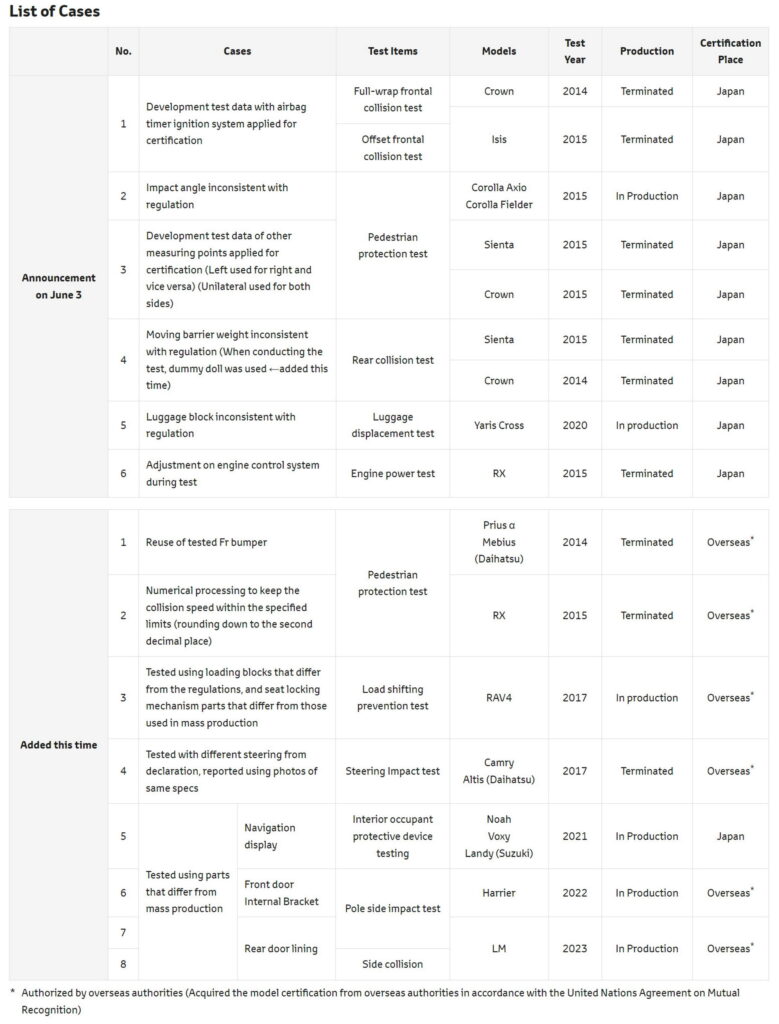

The company flouted regulations by omitting the production navigation display during occupant protection tests for the Toyota Noah, Voxy, and Suzuki Landy minivans (2021). Additionally, non-production parts were used in safety tests for the Toyota Harrier (front door internal bracket) and Lexus LM (rear door lining) in 2022.

Further irregularities emerged in the type approval process for models including the Toyota Camry, Daihatsu Altis (2017), Toyota RAV4 (2017), Lexus RX (2015), and Toyota Prius a, Daihatsu Mebius (2014).

Since many of the affected models were either meant for international markets or have been discontinued, Toyota asserts that current owners “do not need to stop using them.” However, production and deliveries of the Noah and Voxy minivans, which are sold in the Japanese market, were halted starting July 29. Toyota aims to resume production “as soon as possible” once authorities confirm compliance with the standards.

The latest generation of the Toyota Noah (above) and Voxy (below) minivans.

Regarding earlier suspensions from June 3, Toyota announced that shipments of the Toyota Corolla Fielder, Corolla Axio, and Yaris Cross for the Japanese market are set to resume at the start of September, pending MLIT confirmation of compliance with standards. Auto News reports that the production halt contributed to a 13 percent drop in Toyota’s global output last June and could impact quarterly earnings for April through June.

Toyota has blamed a combination of on-site errors and managerial failures for the recent safety testing scandal. The company claims these factors led to the fraudulent practices:

- Unclear internal operational rules for preparing documents required for certification application.

- Insufficient clarification and management of resources required for the certification process.

- Insufficient awareness of the importance of certification work.

- Lack of understanding and involvement of management/executives in the overall certification process.

As part of the announcement, Toyota issued an apology: “It is with deep regret that we were not able to properly conduct our certification operations, and we apologize to our stakeholders for any concern or inconvenience this may have caused them”. The company promised to review its operations and improve infrastructure with more accurate data management, to prevent similar issues from happening in the future.

Below, you can find the full list of irregularities discovered after investigations into Toyota’s facilities in Japan.