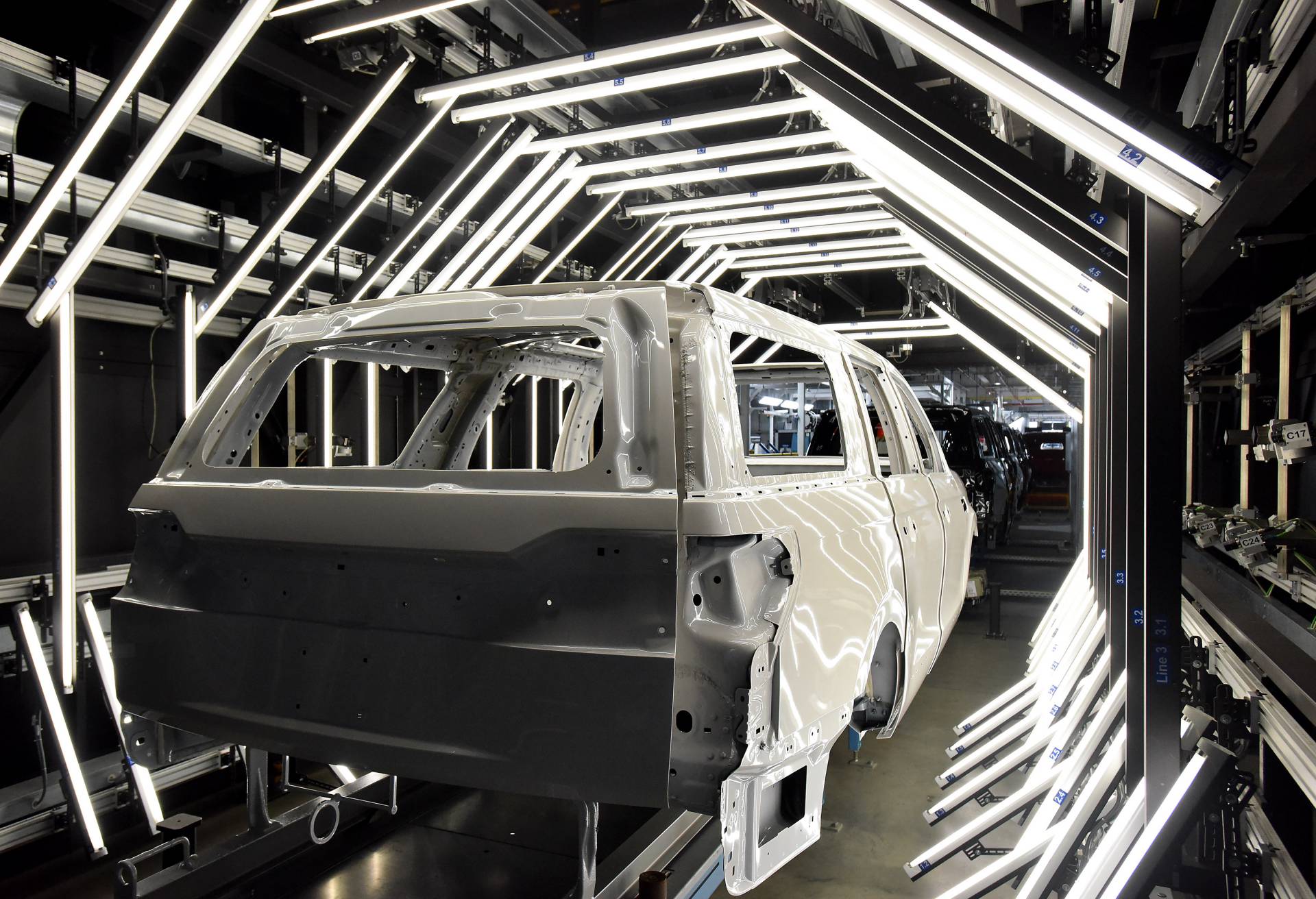

SUVs are the hottest thing right now in the automotive industry so it should come as no surprise that automakers are struggling to keep up with demand.

Take Ford, for example, which has just announced that it is ramping up production of its biggest SUVs, the Expedition and Lincoln Navigator — for a second time. Starting this summer, the Kentucky Truck Plant in Louisville will build 20 percent more full-size SUVs than it currently does.

550 new jobs will be added at the plant to support the production increase which is motivated by a significant surge in demand for the two SUVs. Last year, Ford Expedition retail sales increased 35 percent, gaining 5.6 percentage points in market segment share. Furthermore, the nameplate’s average transaction price increased $11,700 and is now a whopping $62,700, thanks to the switch to an all-new, more expensive model.

As for the Lincoln Navigator, sales exploded by 70 percent in 2018 to 17,839 units, also fueled by the arrival of the all-new generation model for the 2018MY. It was the best sales year for the Navigator since 2007.

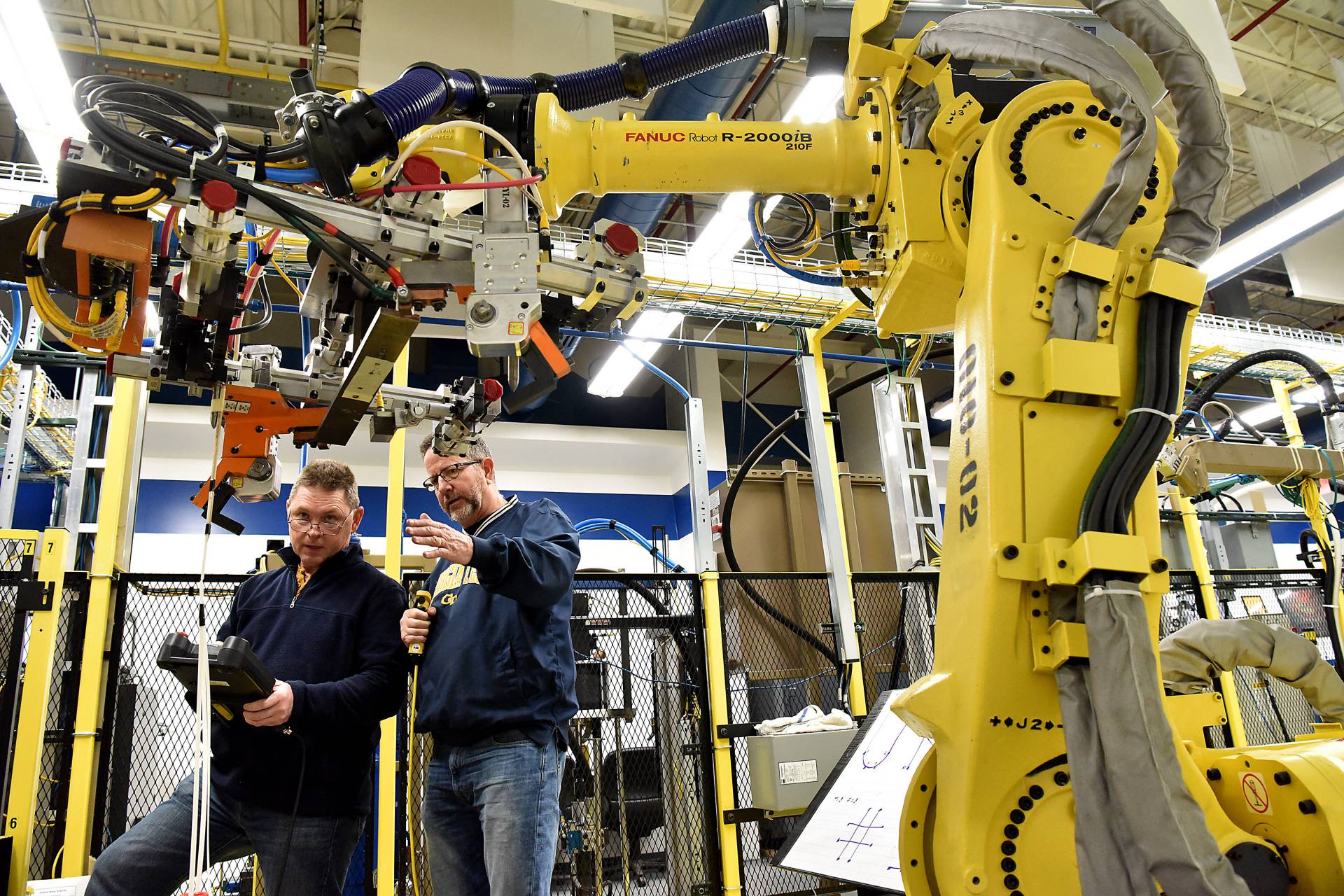

“Kentucky Truck Plant is home to two of Ford and Lincoln’s most successful vehicles. After seeing a continued increase in customer demand for Expedition and Navigator, we are boosting production for a second time to meet it,” said John Savona, Ford vice president, North American manufacturing.

To build more Expeditions and Navigators, Ford has increased the line speed at the Kentucky Truck Plant while adding more workstations and splitting up some tasks. Besides the creation of 550 new jobs, Ford will bring in approximately that same number of workers from the neighboring Louisville Assembly Plant to support the increase in vehicle output. The factory will ramp up vehicle production after the summer shutdown in July.