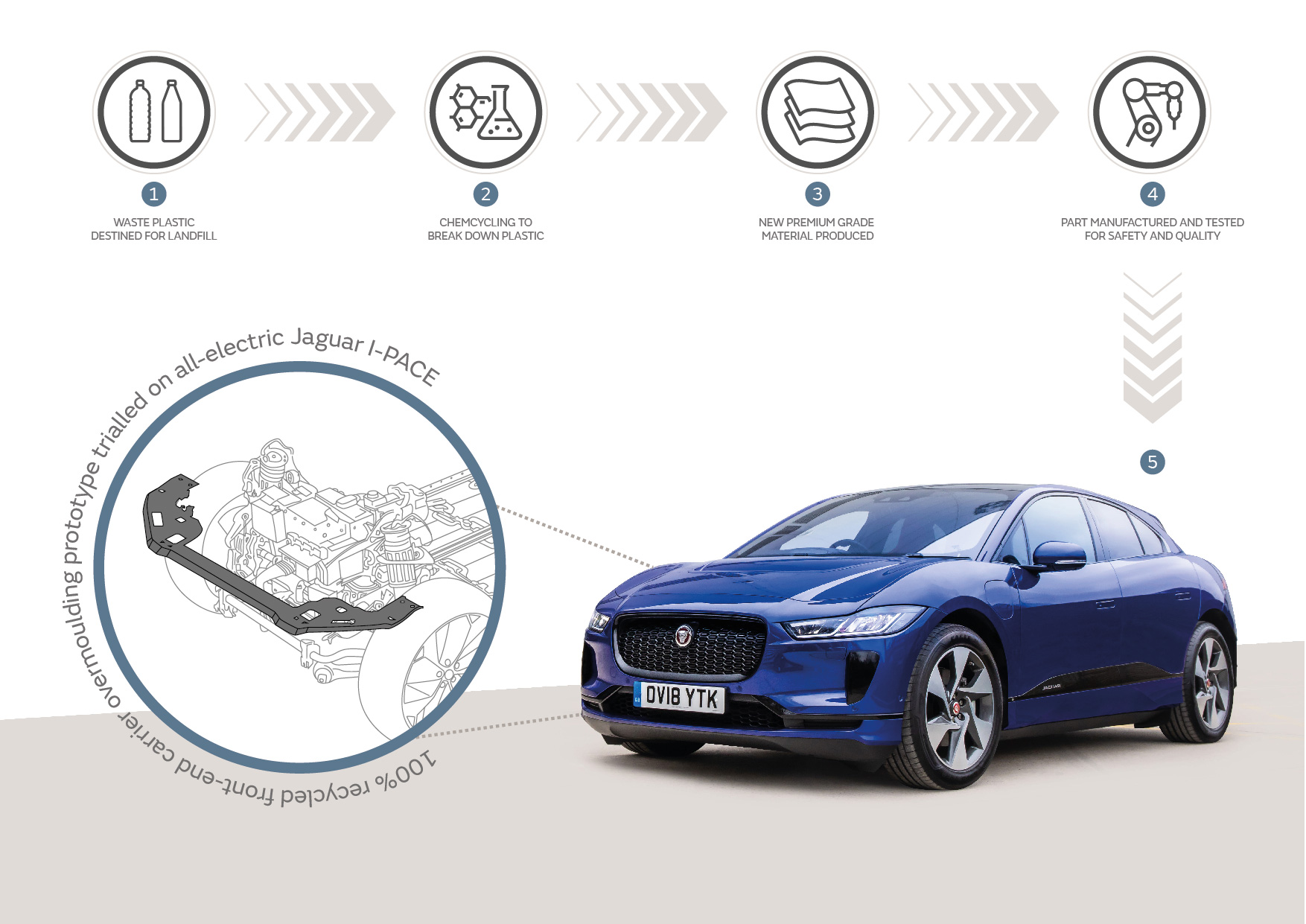

Jaguar Land Rover has teamed up with BASF for a pilot research project dubbed ChemCycling, which aims to tackle the challenges of plastic waste.

The project is looking into ways of taking domestic waste plastic, otherwise destined for landfill or incinerators, and turning it into a new high-quality material that could potentially be used in future Jaguars and Land Rovers.

The plan is to transform waste plastic into pyrolysis oil using a theromochemical process. Then, the material is fed into BASF’s production chain as a replacement for fossil resources, ultimately resulting in a new premium grade that “replicates the high quality and performance of virgin plastics.”

It can also be tempered and colored, which makes it ideal for designing next-gen dashboards and exterior surfaces in cars.

Also Read: Jaguar Land Rover Testing Mood Sensing AI Tech To Make Drivers More Comfortable

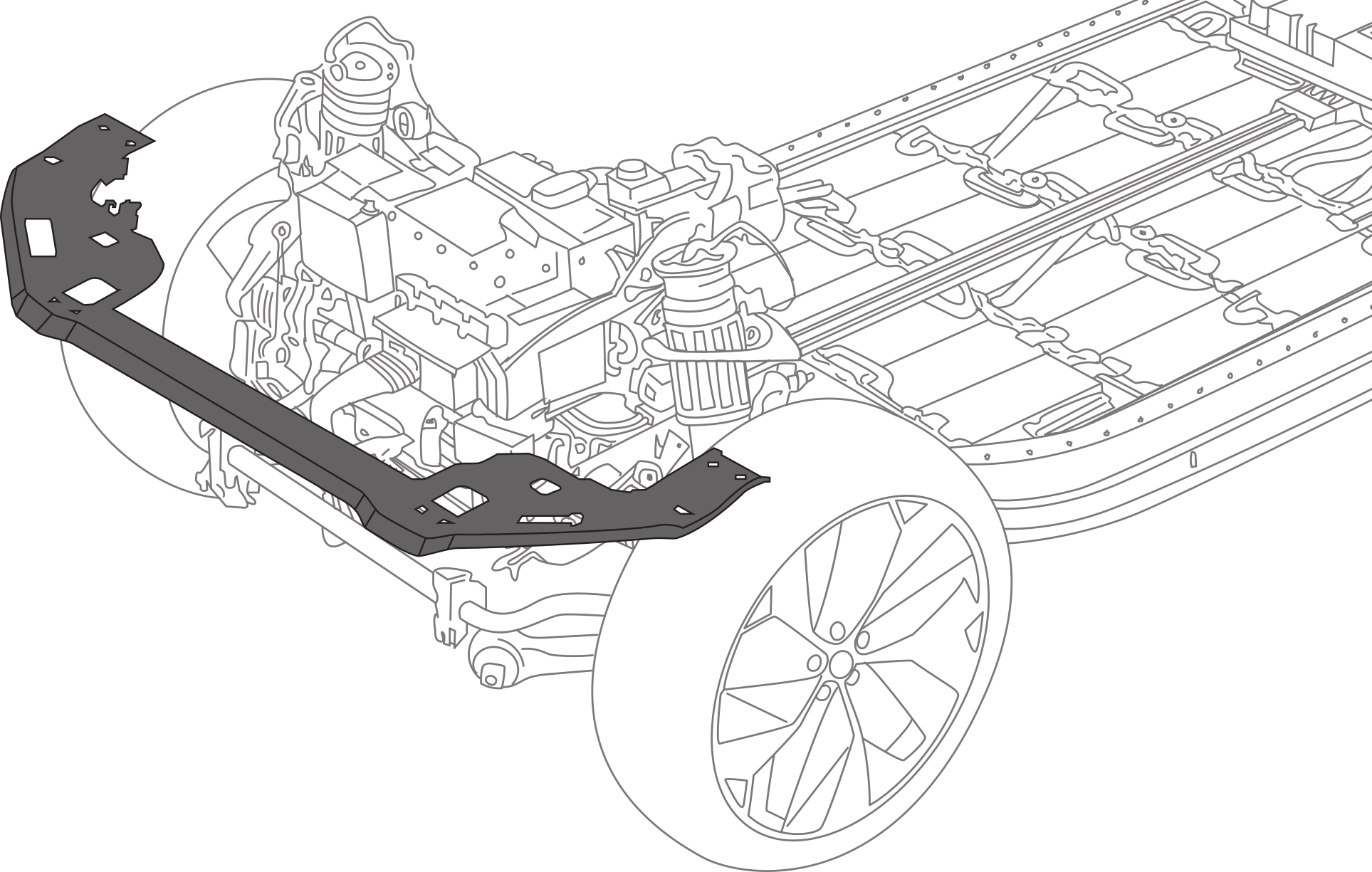

Right now, JLR and BASF are testing the pilot phase material in an I-PACE prototype front-end carrier overmoulding in order to verify that it meets the same safety requirements as the existing original part.

“Plastics are vital to car manufacturing and have proven benefits during their use phase, however, plastic waste remains a major global challenge. Solving this issue requires innovation and joined-up thinking between regulators, manufacturers and suppliers,” said JLR senior sustainability manager, Chris Brown. “At Jaguar Land Rover, we are proactively increasing recycled content in our products, removing single-use plastics across our operations and reducing excess waste across the product lifecycle. The collaboration with BASF is just one way in which we are advancing our commitment to operating in a circular economy.”

This trial program is the latest example of JLR’s commitment to addressing the challenges of waste plastic. The British automaker has already collaborated with Kvadrat on alternative seat options that combine a durable wool blend with a technical suedecloth made from 53 recycled plastic bottles per vehicle.