BMW has started sharing more details about its upcoming INext electric SUV, including the new innovative ways it has in store for its series production.

The upcoming electric SUV is set to enter production in 2021 at BMW’s Dingolfing plant, using the same assembly line with ICE-powered and plug-in hybrid models. Until then, the German car maker will build up to 100 prototypes of its new model in its Research and Innovation Center, testing innovative solutions for series production that includes a process called rotary bonding.

With the rotary bonding process, BMW is able to join aluminum with high-strength steel sections by using the friction heat that’s generated when a steel element pierces an aluminum part. Thanks to this heat, the two parts are fused together.

Also Read: 2021 BMW iNext Electric SUV Reveals More Of Its Interior

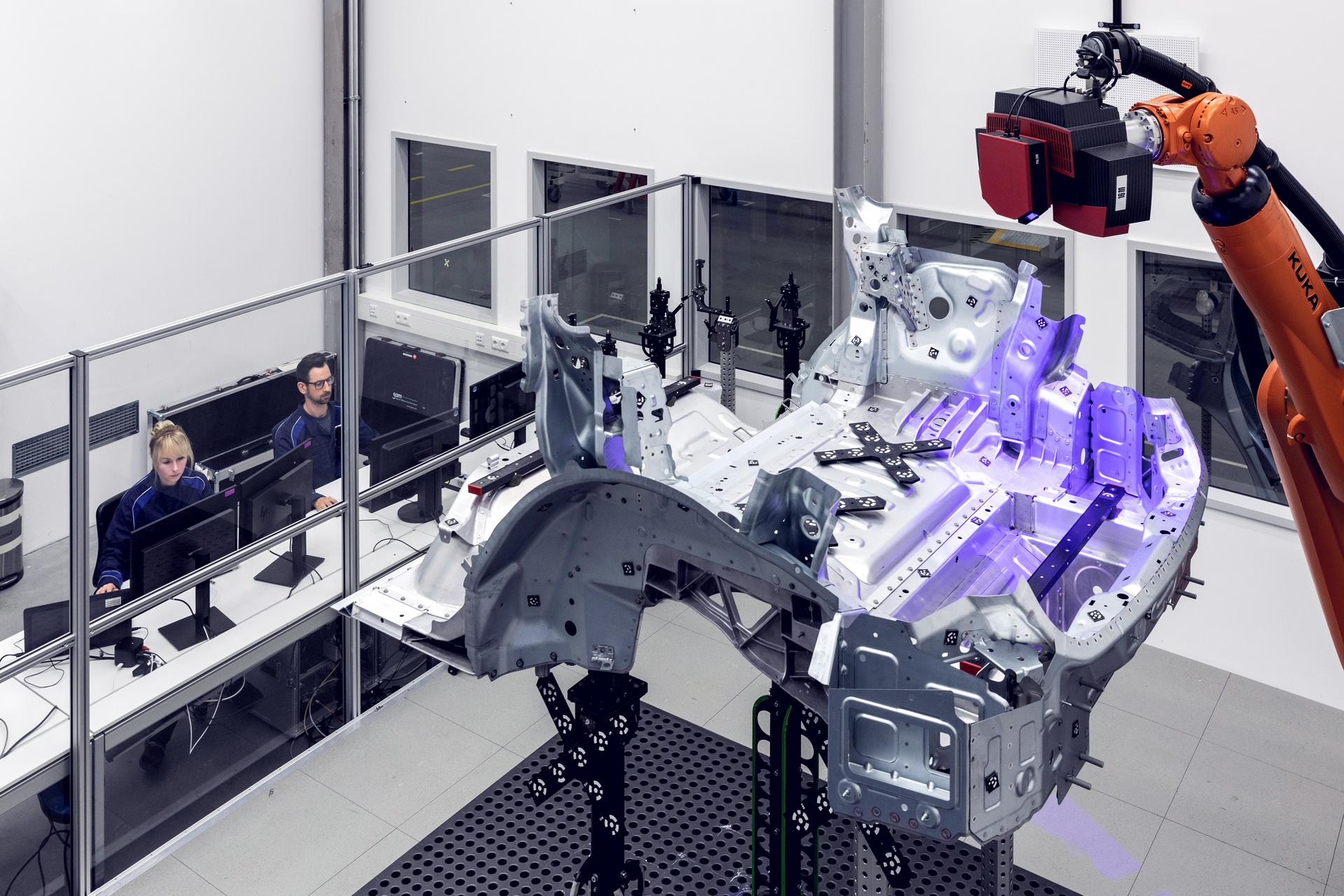

Once assembled, the body-in-white undergoes detailed checks by laser radar, eliminating the need to place measurement points manually, which has been the default way until now. The automated measurement technology quickly identifies individual surface characteristics, dramatically shortening the time required for the whole checking process.

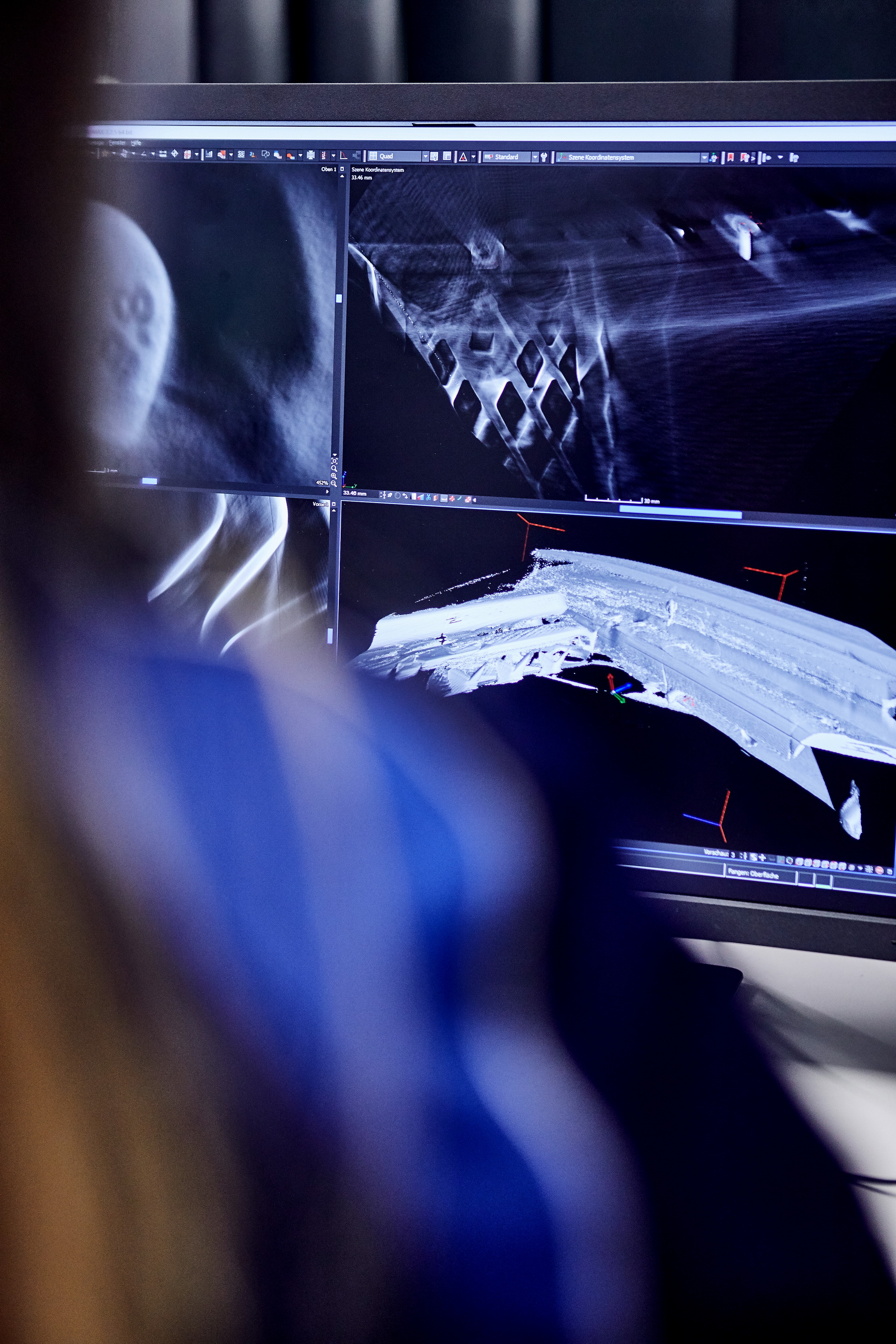

BMW also uses computer tomography to test new materials and bonding techniques on prototypes after they have been built; four robots scan the vehicle using X-rays. The data from the scan is used to create a multilayered 3D image, enabling engineers to examine all the components in minute detail without having to dismantle the vehicle.

The upcoming BMW INext will be an X5-sized electric SUV powered by a fifth-generation electric powertrain, featuring the company’s most advanced systems for highly automated driving. BMW claims that its technology flagship will also offer a driving range of over 372 miles (600km), once it arrives in the market.