Ask any car journalist what they want to do, and they’ll tell you they want to travel the world and drive the finest machines. Trucks and buses aren’t on our daily agenda, but getting behind the wheel of these vehicles that most of us do not pay much attention to out on the road was a delightful yet frightening experience.

Everything started out with an e-mail from the Traton Group, which is part of the Volkswagen Group and encompasses the MAN, Scania, Volkswagen Caminhoes E Onibus (VWCO) and Rio brands. Together, they plan to revolutionize global transportation, while following the latest trends in the industry such as electrification and autonomous driving. But we’ll get to that later in this story. For now, I can tell you that I responded to their invitation for the Traton Innovation Day, which was hosted in Sweden, on October 2.

Not knowing exactly what to expect, I packed my bags and went to the airport. Soon, I found myself in Stockholm, heading to the hotel for a formal dinner and a good night’s sleep, as the shuttle was about to pick me (and another 120 journalists from all over the world) up at 7:30 in the morning, the next day. Destination: Sodertalje, a small city located about 40 km (25 miles) south-west of Stockholm, which is home to the Scania Test Center. The site is where Traton’s brands test and develop all kinds of machines, before putting some of them into production and eventually shipping them all over the world. It’s also where I jumped behind the wheel of some behemoths for the first time in my life, on a regular car driving license and after they checked my breath for alcohol – the night before could’ve been wild, you know.

Navistar LT Series – “I hope I don’t kill anyone”

As I approached the first vehicle I was about to drive, I was thinking “I hope I don’t kill anyone”. And for good reasons, as I aimed for the sky, asking to have a go in the Navistar LT Series, the biggest one there. This is an 18-wheeler aimed at international markets that’s not for sale in Europe because, well, it’s too simply big. I climbed on board, smiled at the instructor asking him to go easy on me and got some reassurance that I’ll do just fine, even if the biggest vehicles I had driven up to that point were mere vans and SUVs.

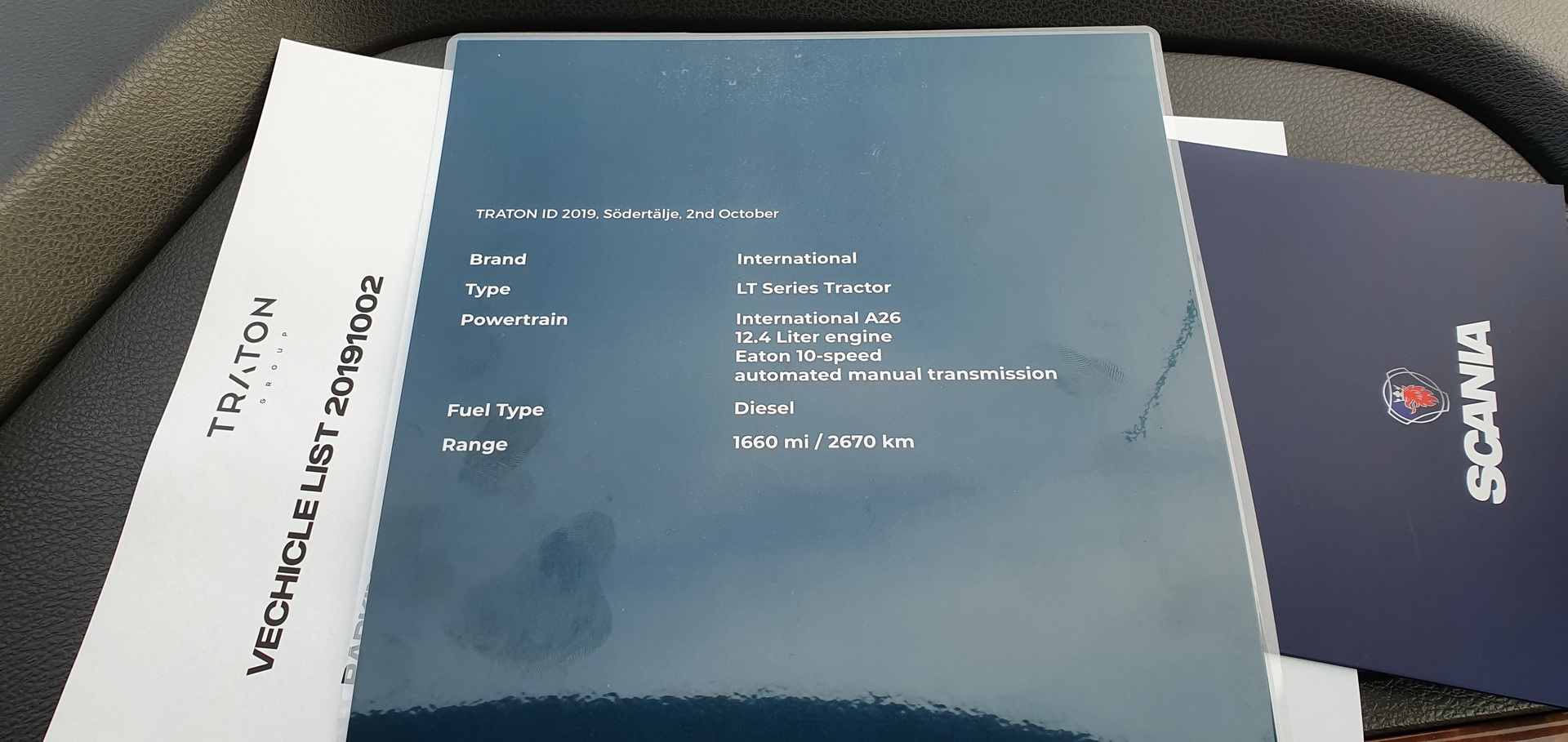

I then buckled up and took a closer look at the gigantic steering wheel and dashboard with what seemed to be countless buttons. “Do I need to learn what all of these do?”, I asked under my breath. “Of course not”, the answer came, “but these are the parking brakes (tractor and trailer) and that’s the gear selector. Disengage them, shift into Drive and push the throttle gently.” Before I realized it, the 12.4-liter diesel engine came to life and off I was, seeing the closed course for the first time from such an elevated driving position that it would’ve made even the proudest SUV owners jealous.

The 3-kilometer (1.9-mile) long course includes hill climbing and descending, tight turns and long straights, pretty much everything the average motorist will encounter out on public roads. I became quite comfortable holding that big steering wheel in my hands in no time, to my surprise. But my confidence was about to be shattered as I approached the first turn, thinking “I easily got this”. I was wrong, because, you see, towing a big trailer behind an SUV doesn’t compare to towing 10 tons (22,046 lbs) of cargo in an 18-wheeler. And the trailer was only half-full.

As I stepped on the brake, nothing happened, so I panicked and pushed it harder. That would’ve brought a car to a full stop in no time from about 40 km/h (25 mph) as I was doing here. But it only gently stopped the truck. Luckily, I had my poker face on and the instructor didn’t know that I came close to ruining my pants and that nice leather seat – or so I hoped. “Don’t worry, you’re doing great”, he said, just as I was turning the wheel to climb the first hill.

A quick look at the dials revealed that I was going just over 30 km/h (19 mph) again, and I was in 6th gear (out of 10). That was strange. As I escaped my first tight turn and I started catching speed again, I realized that gravity wasn’t my ally, as I was going too fast downhill and another tight curve was coming. “Push this lever down to engage the engine brake”, the instructor said. “It’s a multi-step process”. And I did, while also pushing hard on the brake pedal. Hey, I wasn’t going to take any chances this time.

As I became more confident behind the wheel, the course ended and I had to park the truck. Luckily, that was very easy, as they thought that not everyone can park a 20-meter (65.6 feet) long vehicle on the first try. “So, what are the specs of the engine?”, I asked, as I shifted into Neutral and engaged the parking brakes. “450 metric horsepower and 1,700 pound-feet (2,300 Nm) of torque. It has a 1,660-mile (2,670 km) autonomy”, the instructor replied. I thanked him for going easy on me on my first close encounter of the third kind with a truck, thinking that I need to get myself behind the wheel of a bus, too.

Driving a bus? Piece of cake

On a closer look at the vehicles available for test drives, I saw the next one I knew I wanted to drive: the MAN Lion’s City 18 G. This one’s powered by a natural gas engine with an efficient hybrid system. The 9.5-liter, inline-six produces 315 hp (319 PS / 235 kW) and 1,033 lb-ft (1,400 Nm) of torque, paired to an automatic gearbox. The hybrid system adds an intelligent management to the powertrain for increased efficiency, keeping the electronics on at a red light, when the ICE is automatically turned off, while also acting as a booster during acceleration.

After getting to know some of the specifics of the bus, I jumped into the driver’s seat, pushed a button to close the front door, stepped on the brake pedal and disengaged the parking brake. I then shifted into drive and off I was. The rear-engine, rear-wheel drive layout would’ve have made me excited, but this was almost as long as the Navistar and weighed several tons. And since it was empty, it was very easy to master it on the same course. To my surprise, the adrenaline rush was gone before I reached the first turn, and stayed like that until my hands came off the steering wheel.

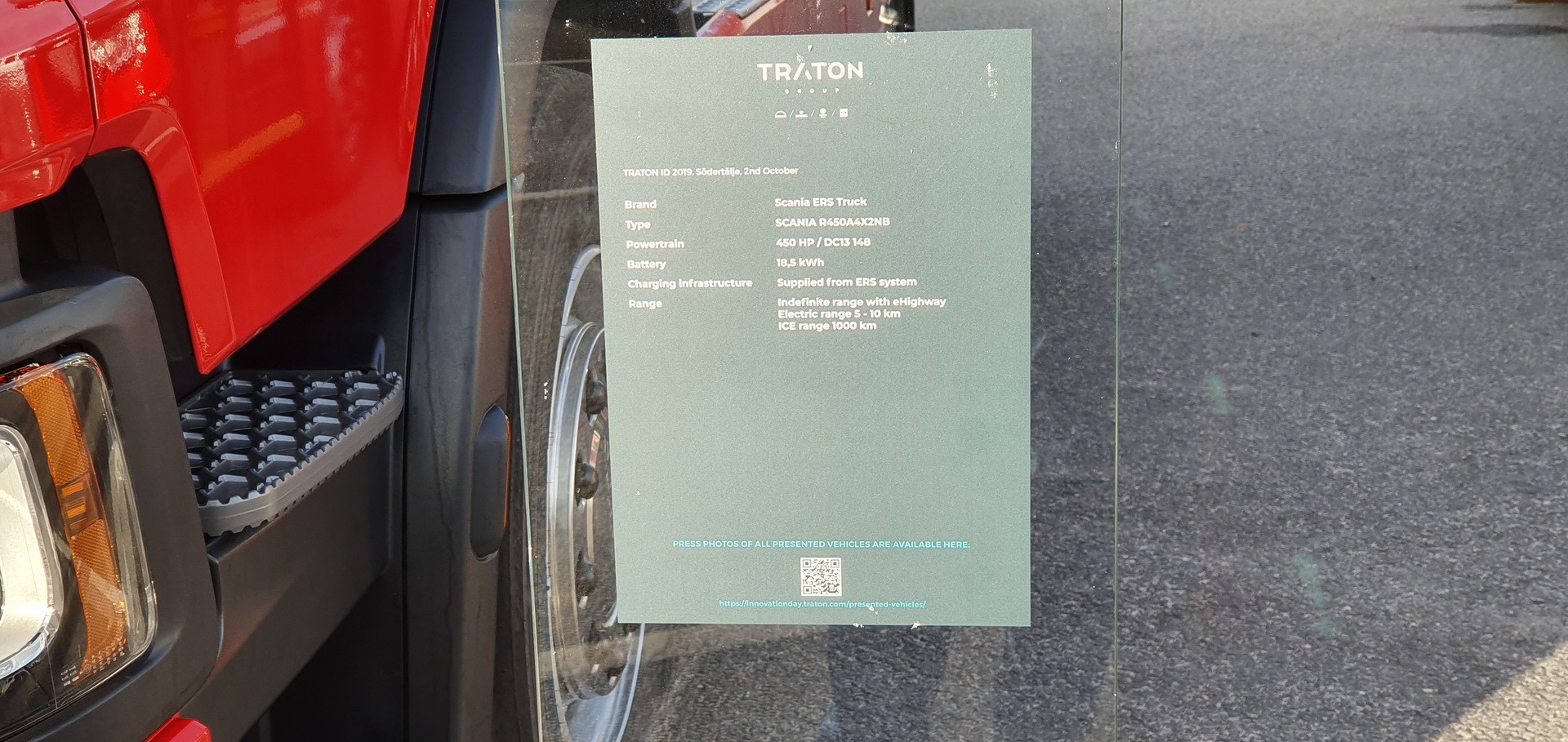

Close encounter of the third kind with an electric truck

“I should check out an electric truck next”, I thought. And they introduced me to the MAN eTGM 26.360 E 6×2 LL. It has 354 hp (360 PS / 264 kW) and a whopping 2,286 lb-ft (3,100 Nm) of torque, powered by a 185 kWh lithium-ion battery that supports 22 kW AC and 150 kW DC fast charging. It has a range of up to 112 miles (180 km), but I was going to enjoy a small fraction of that.

The idea of experiencing the instant torque in a truck was exciting. I disengaged the parking brake, shifted into drive and gently lifted off the brake. The vehicle started moving backwards, as I quickly pushed the brake pedal again. “Is it in reverse?”, I was thinking. It wasn’t, so I repeated the procedure, only this time I stepped on the throttle sooner. And off it went, in complete silence. Mastering the corners and hill climb felt like child’s play at this point, and the powerful motor did the job very good.

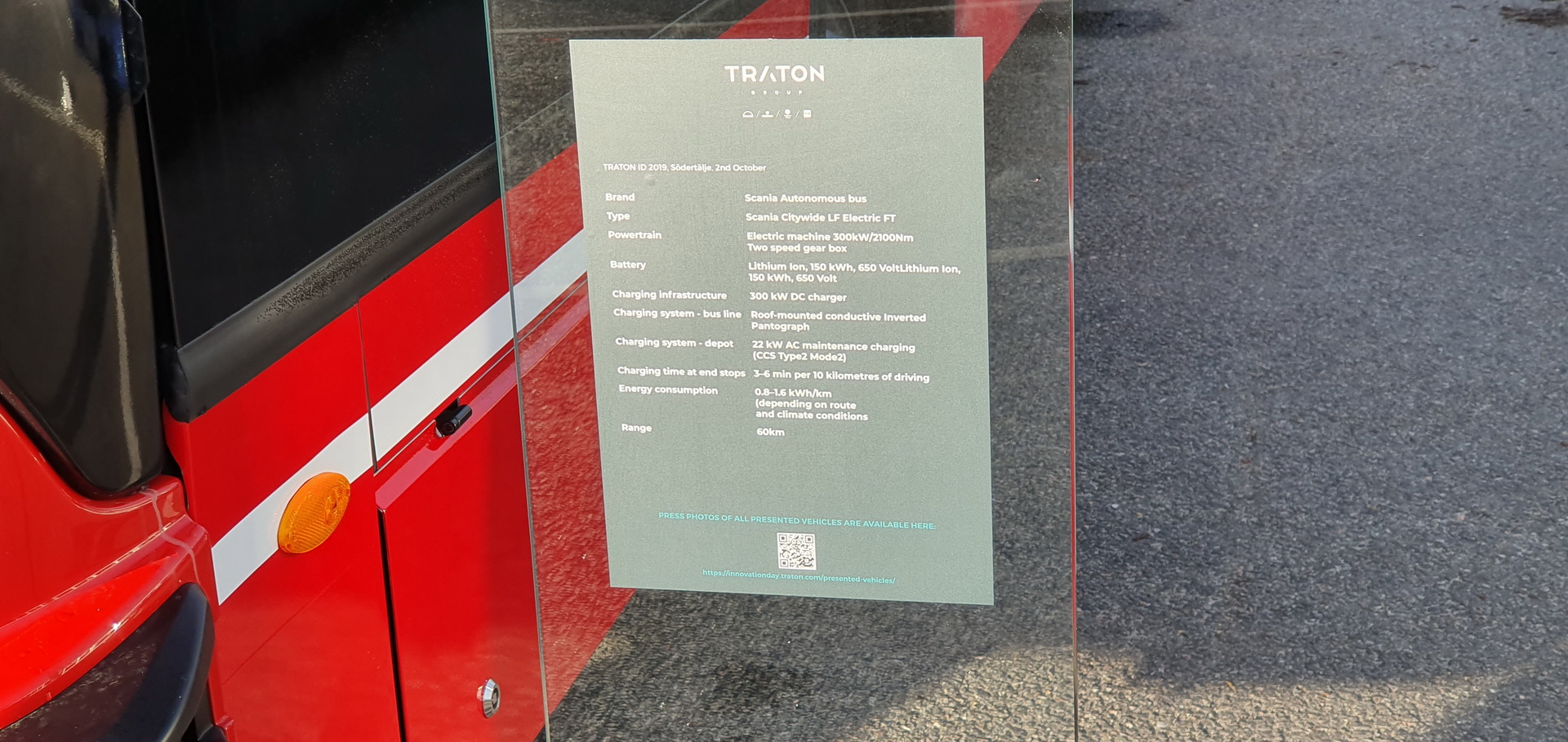

The Scania electric bus prototype

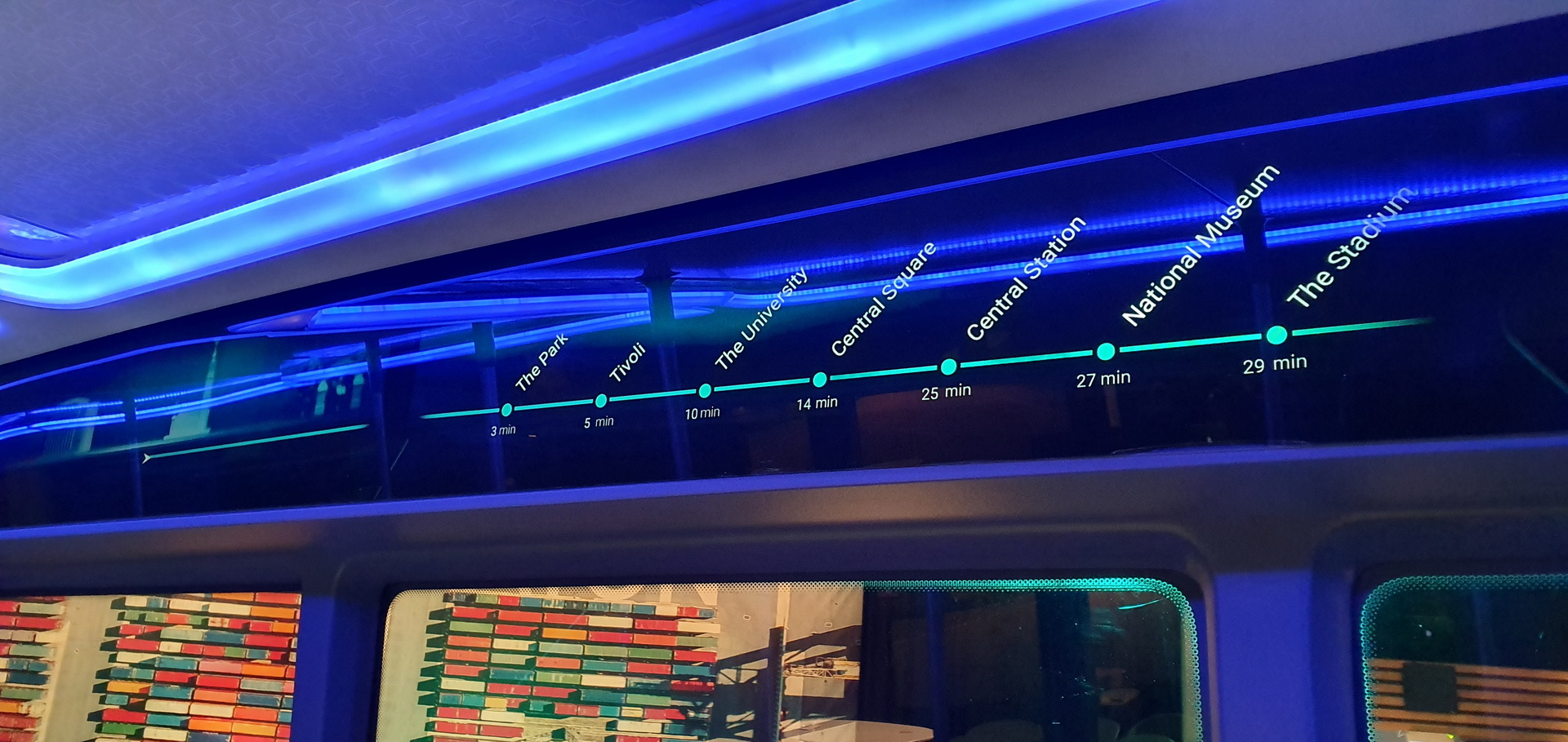

As the vehicles I drove got smaller and smaller (perhaps I should have started small and work my way up, and not the other way around), the enthusiasm started fading away. But I wasn’t going to give up that easy. After all, I still felt like a kid in a candy store. So, I figured they must have a prototype of some sorts that I could check out up close. And to my luck, they did: the Scania Citywide LF Electric, a BEV bus that was about to be demonstrated on the course. They didn’t let journos drive it, but we did enjoy a quiet run in it. “How was it?”, they asked as I got up from my seat. “Quiet. By the way, I forgot to buy a ticket”. They probably heard that joke all day long, but they did laugh.

Driving that ‘electric Volkswagen Crafter’

“Okay, now what?”, came through my mind, and then I remembered I saw that “electric Volkswagen Crafter” on display. It’s the MAN eTGE, a front-wheel drive panel van, with a 134 hp (136 PS / 100 kW) motor, 1-speed transmission and 35.8 kWh battery. The range? A mere 71 miles (114 km) in the WLTP test cycle. How was it? Pretty fast for what it is, very quiet and I realized that it features one-pedal driving. This means that it applies pressure to the brakes as you lift off the accelerator, a process that recuperates energy and stores it into the battery. “Pretty neat”, came through my mind as it started raining mid-course.

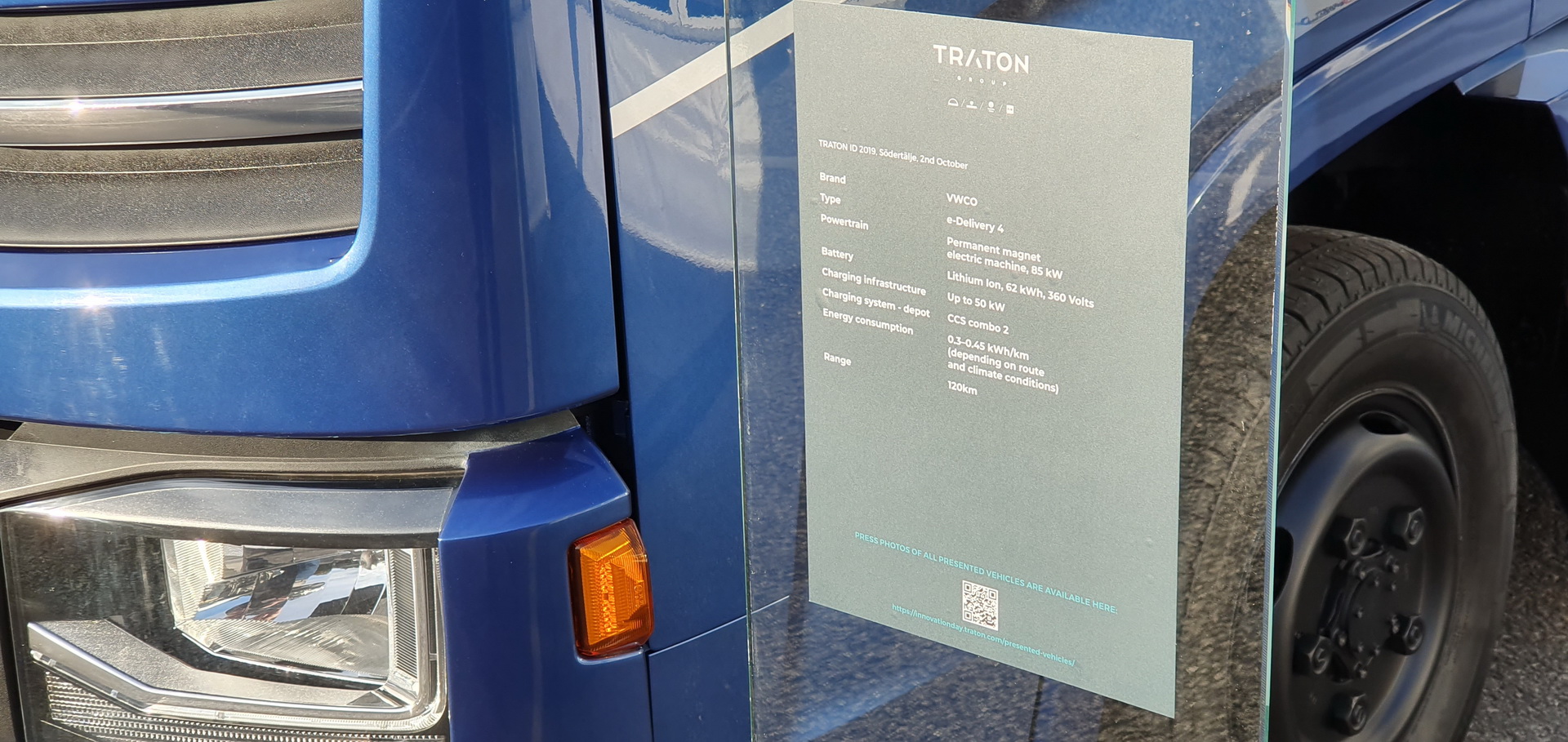

The Brazilian Volkswagen electric truck

At this stage, I also had the Volkswagen e-Delivery 11 booked for a short go. As its name implies, it too is electric, featuring a 268 hp (272 PS / 200 kW) motor and a 130 kWh lithium-ion battery that gives it a range of 99 miles (160 km). As the weather drastically changed, I was happy just to be surrounded by windows and have a couple of air vents blow hot air in my face. The e-Delivery 11 has a very basic interior and a 2-stage brake pedal that takes very little time to get used to. The instructor said that in Brazil, where it’s being sold, they’re training their drivers to learn how to use this feature, as it saves energy and improves the range.

Scania AXL autonomous truck concept demonstration

As I checked the time, I realized that I have one and a half hours left before the shuttle was supposed to take me to the airport. So, that’s enough time to check out another toy, which is the Scania AXL Concept, an autonomous vehicle designed to be used in mines and on large construction sites. To see it in action, we went to a nearby facility, where we were instructed to stay behind the fence, up on a small hill, during the briefing.

When the course was clear, the study came out from behind a truck, did a few turns and stops, before facing a more expensive obstacle: a Volkswagen Golf Mk7. The driver parked the hatchback in front of the AXL and left. The sensors, cameras, radars and GPS receivers then did a fine job at identifying it and ordered the computer to reverse and take a small detour around it. As the cabless concept came to a full stop, we were allowed to see it up close.

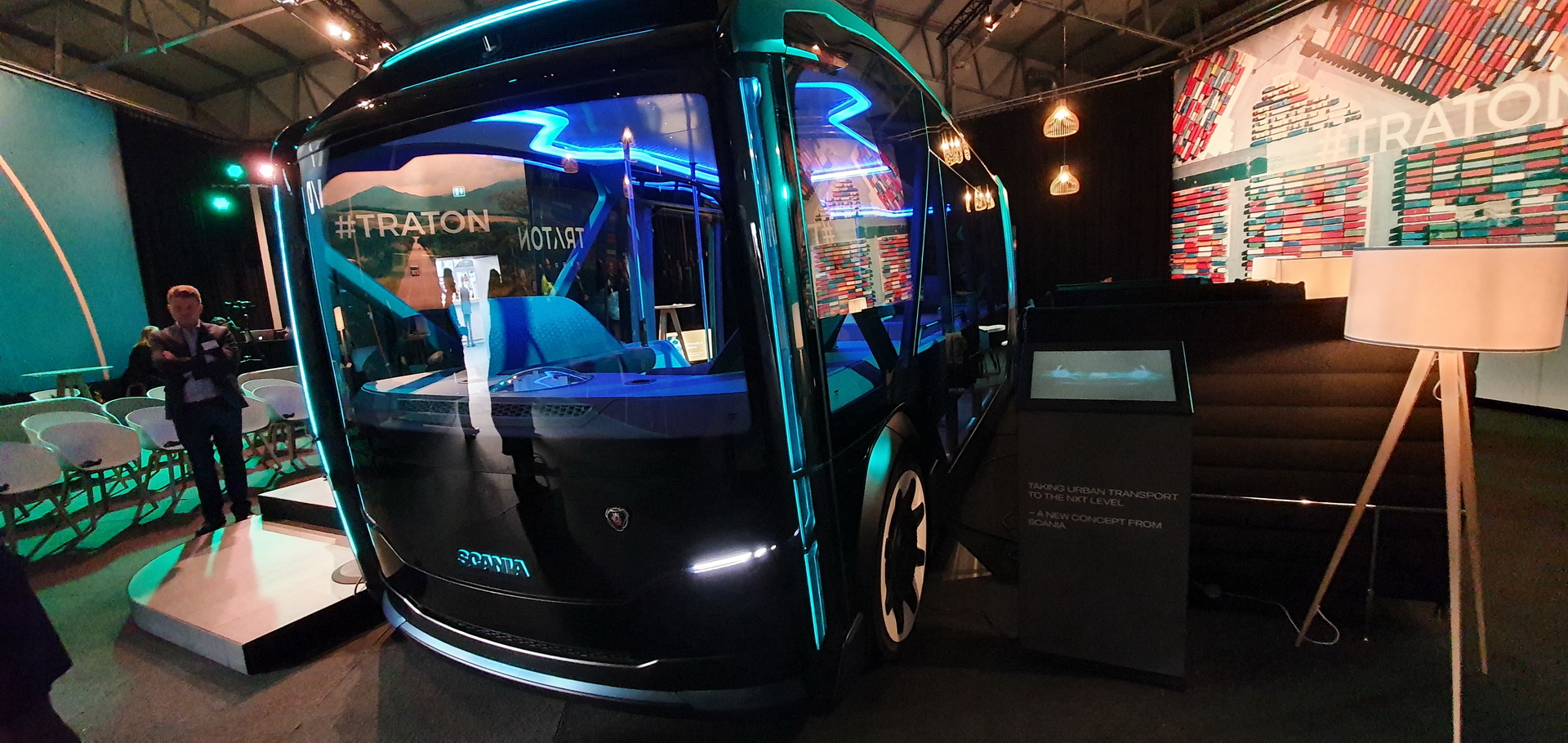

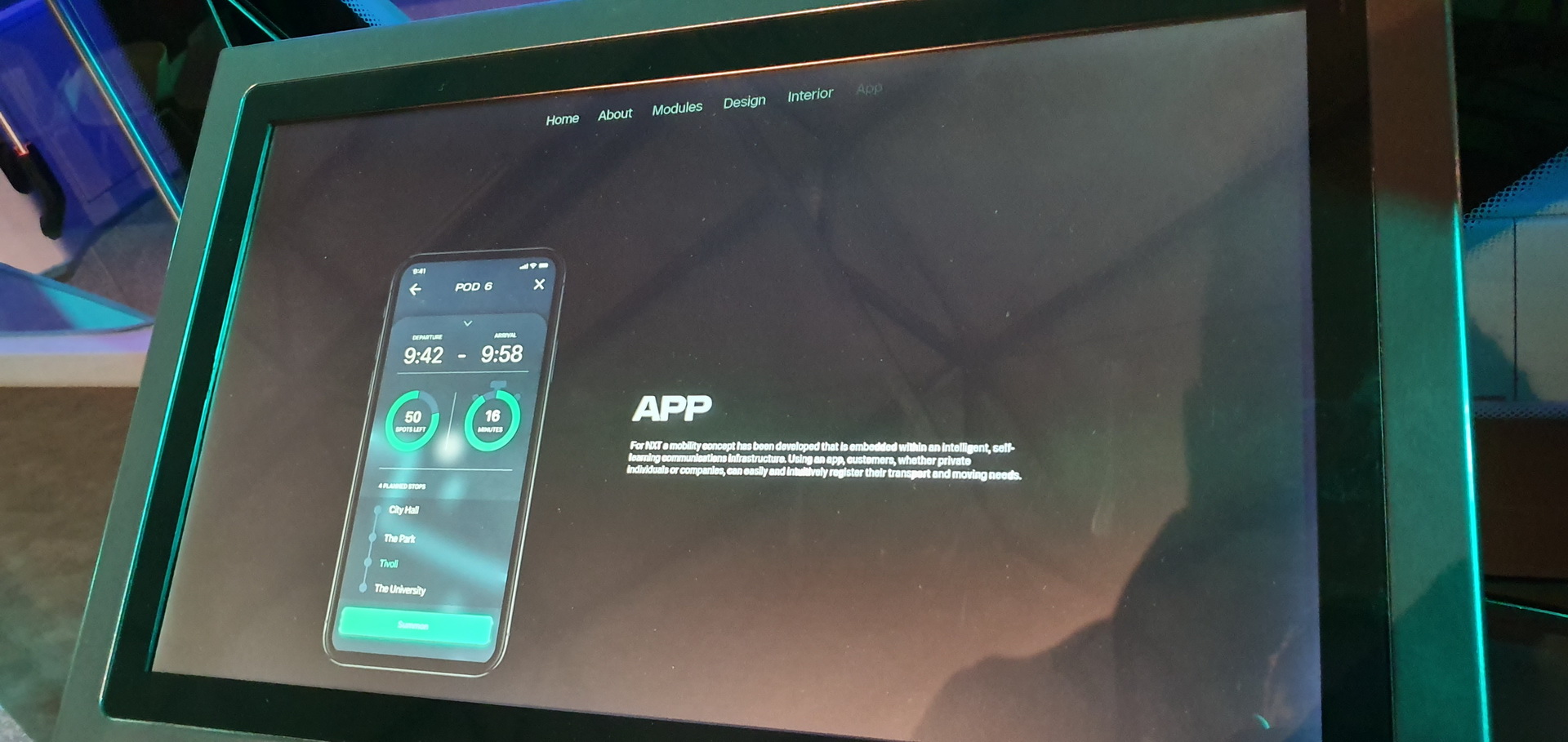

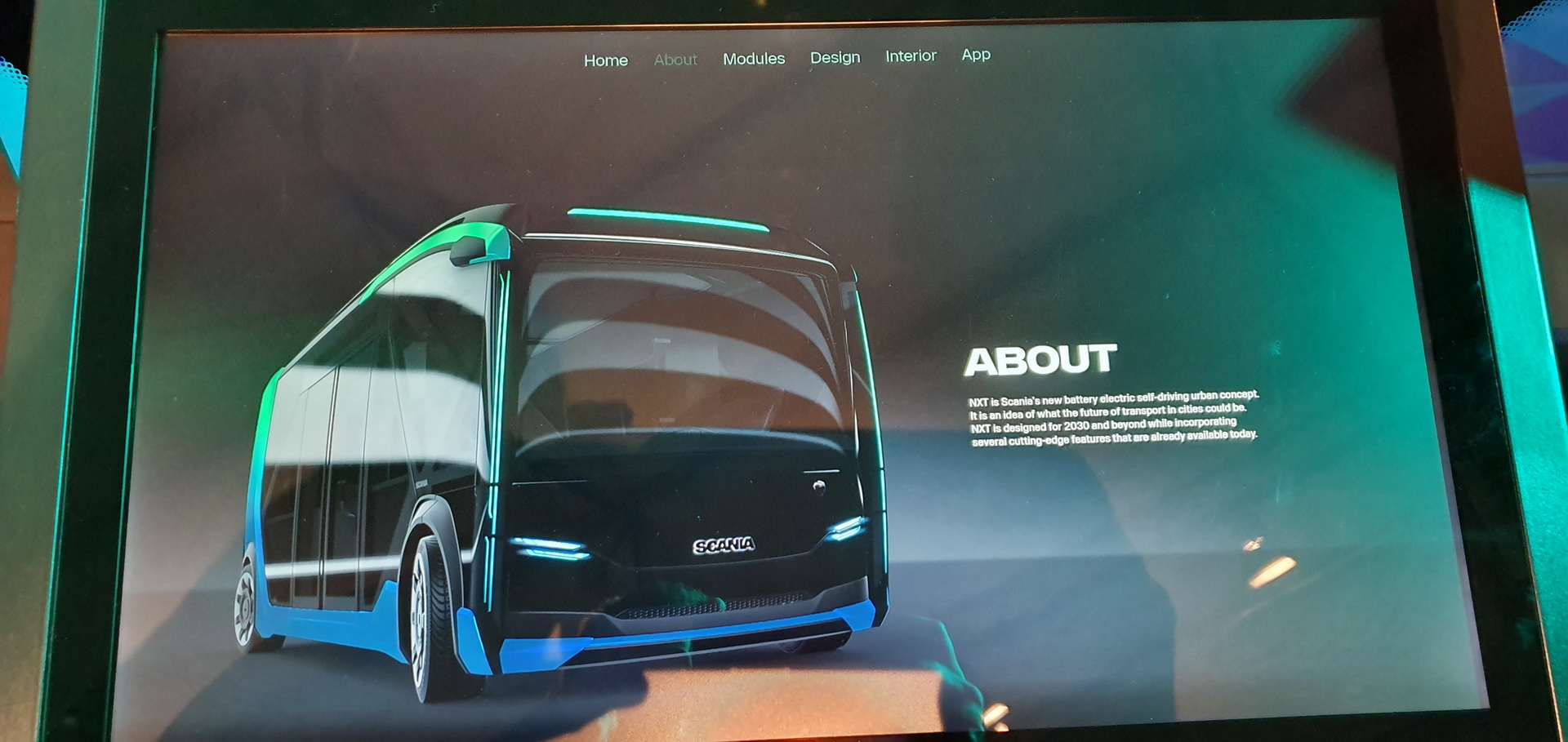

Scania NXT is a concept of the future

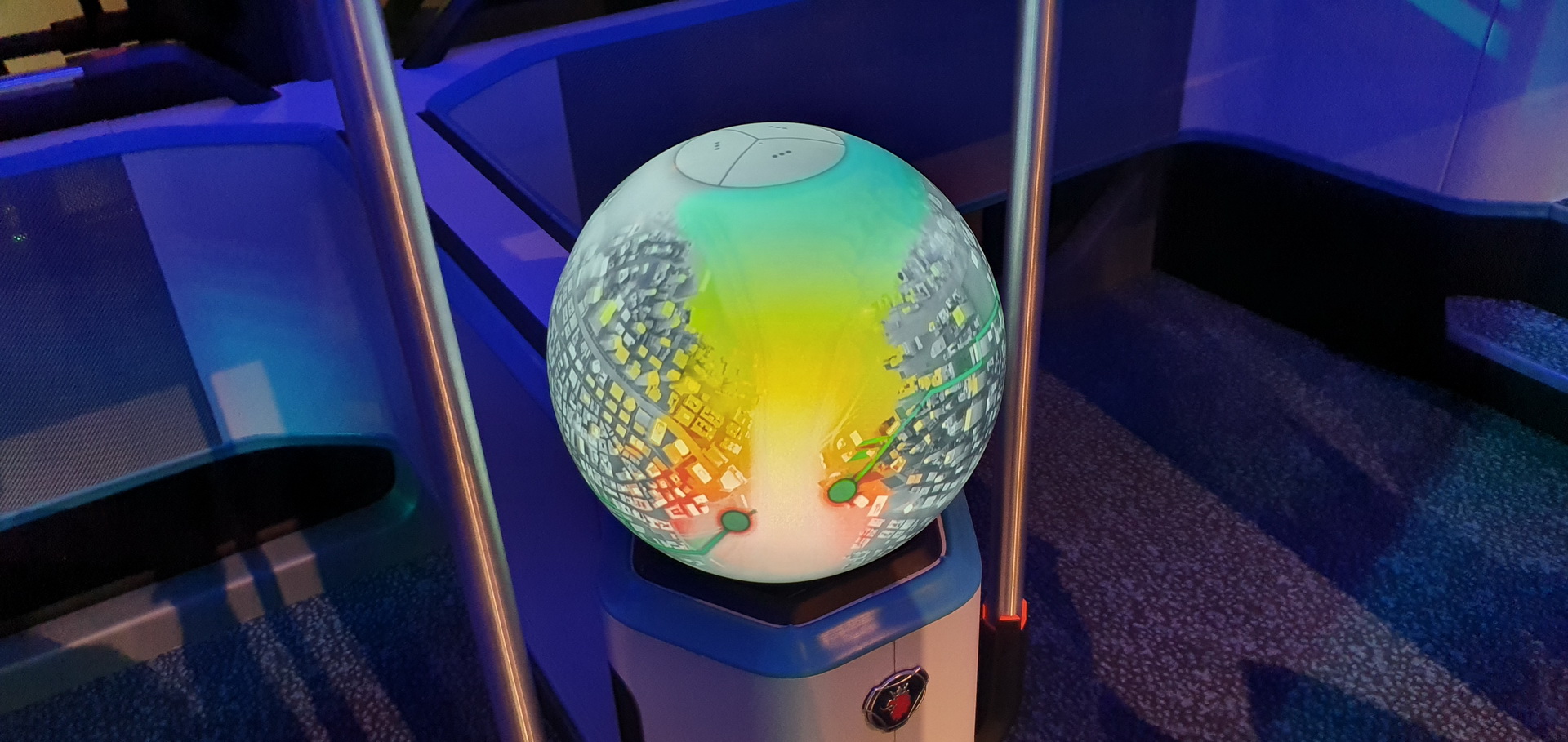

Presented a few months ago over the world wide web, the Scania NXT Concept was brought to the Traton Innovation Day, dropping jaws with its futuristic styling and looking pretty much like a mobile disco. It features three modules, with the middle one being replaceable. As it sits, it’s 8 meters (26.2 feet) long and can fit two Euro pallets on the floor. The 162 kWh battery powers four electric motors, one on each wheel, that produce a combined 472 hp (479 PS / 352 kW). The study can travel, according to Scania’s estimations, for 152 miles (245 km) on a single charge.

TRATON’s future plans

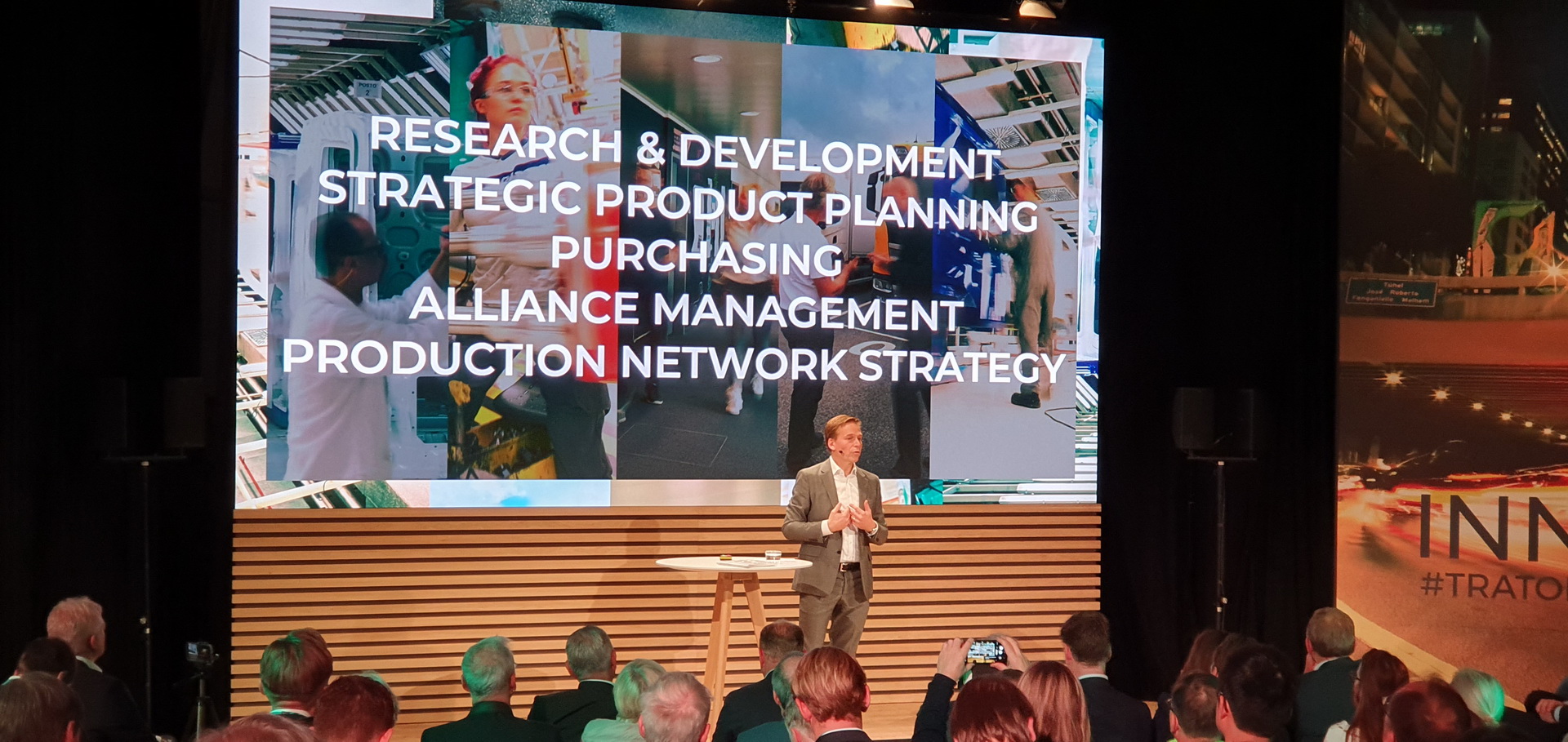

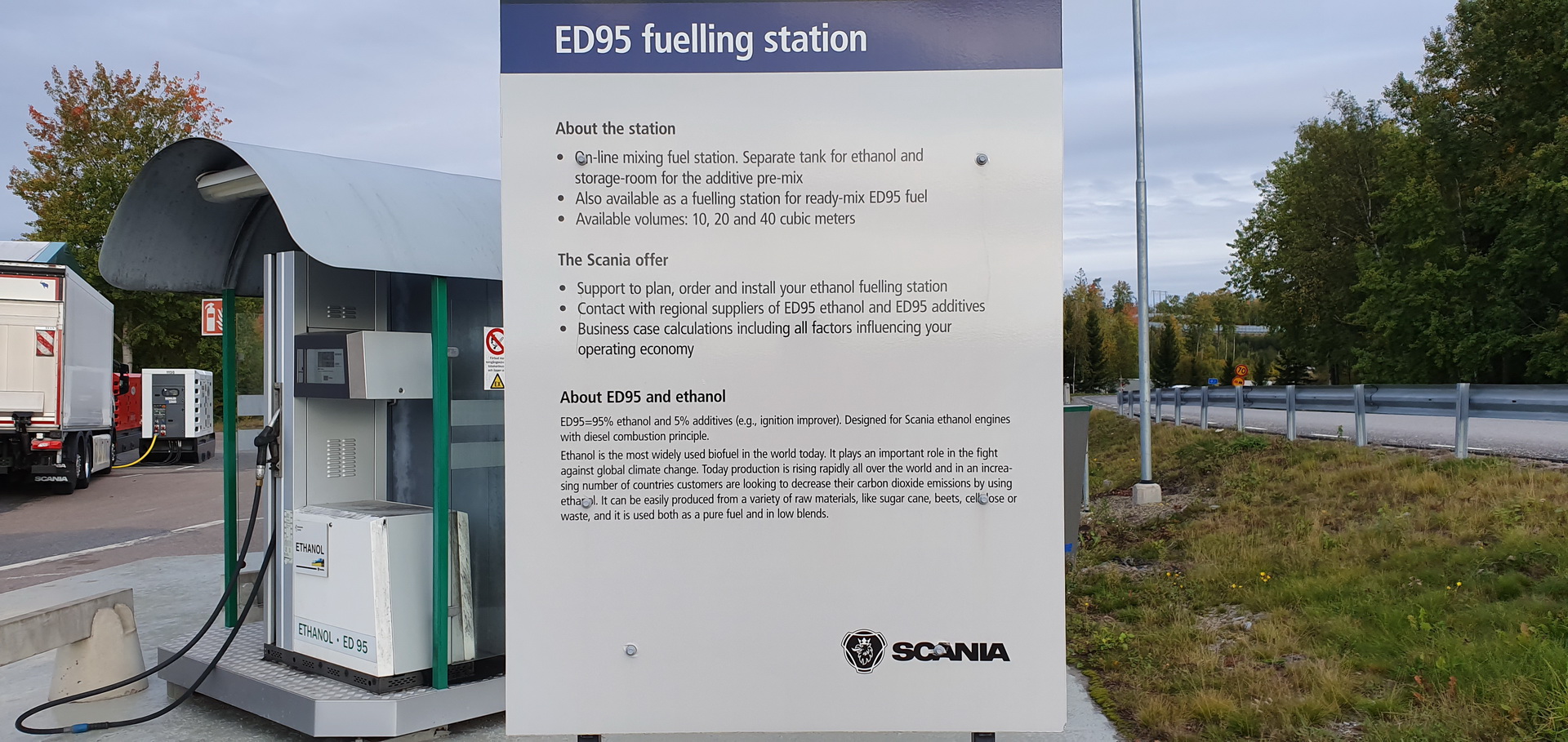

Getting to drive these trucks and buses was only the icing on the cake, as the goal behind the entire event was to find out about Traton’s ambitious plans for the future. The Group will invest more than €1 billion ($1.1 billion) in e-mobility R&D by 2025, focusing on alternative fuels, connected driving and new technologies. Biofuels, ethanol, liquefied natural gas (LNG), compressed natural gas (CNG), hybrid, plug-in hybrid and battery-electric solutions will help reduce CO2 emissions.

Development costs will be spread across MAN, Scania and VWCO. Furthermore, the first two brands will benefit from a new modular electric powertrain toolkit that will be used next year in the production electric city buses.

Before the end of the year, Scania wants to operate an autonomous and electric bus to transport passengers in the Stockholm metropolitan area. They are also testing fuel-cell trucks with a Norwegian company, which will try out an electric truck later on. MAN, on the other hand, is testing out electric trucks in Austria with local customers, stating that it will further expand the production of the eTGM.

At the same time, VWCO has formed an e-consortium in Brazil that will help speed up the introduction electric trucks in the country, providing support from manufacturing to setting up the charging infrastructure and managing the vehicles throughout the lifecycle of the battery pack. VWCO has also signed the world’s largest purchase intention agreement for electric trucks, with 1,600 units being ordered by a Brazilian beer and beverage producer.

“If all necessary prerequisites are in place at the right time, I expect for our Group that in the next 10 to 15 years, every third of our trucks and buses can have an alternative drivetrain, most of them fully electric”, said CEO and Member of the Board of Management of Volkswagen AG, Andreas Renschler. “One of the prerequisites is that the infrastructure for alternative fuels and electricity must be fully available to guarantee seamless operation.”