With the Polestar 2 featuring a “vegan interior,” the Swedish brand decided to further focus its attention on full-circle sustainability for its vehicles in a bid to reduce weight, cut plastic content and lessen waste material by using natural and recycled materials.

For example, Bcomp’s powerRibs and ampliTex technologies can turn natural fibers into lightweight interior panels for cars. Such a bio-material is said to be ideal for use in crop rotation programs.

“It’s clear that to be truly sustainable we have to evaluate every element that goes into our cars,” said Thomas Ingenlath, Polestar CEO. “For Polestar, sustainability is not just about the electric powertrain. With the development of these innovative new solutions that we will introduce in our future cars we make a strong statement of our intentions.”

Read Also: Polestar 2 Towing Capacity Rated At An Impressive 3,300 Lbs

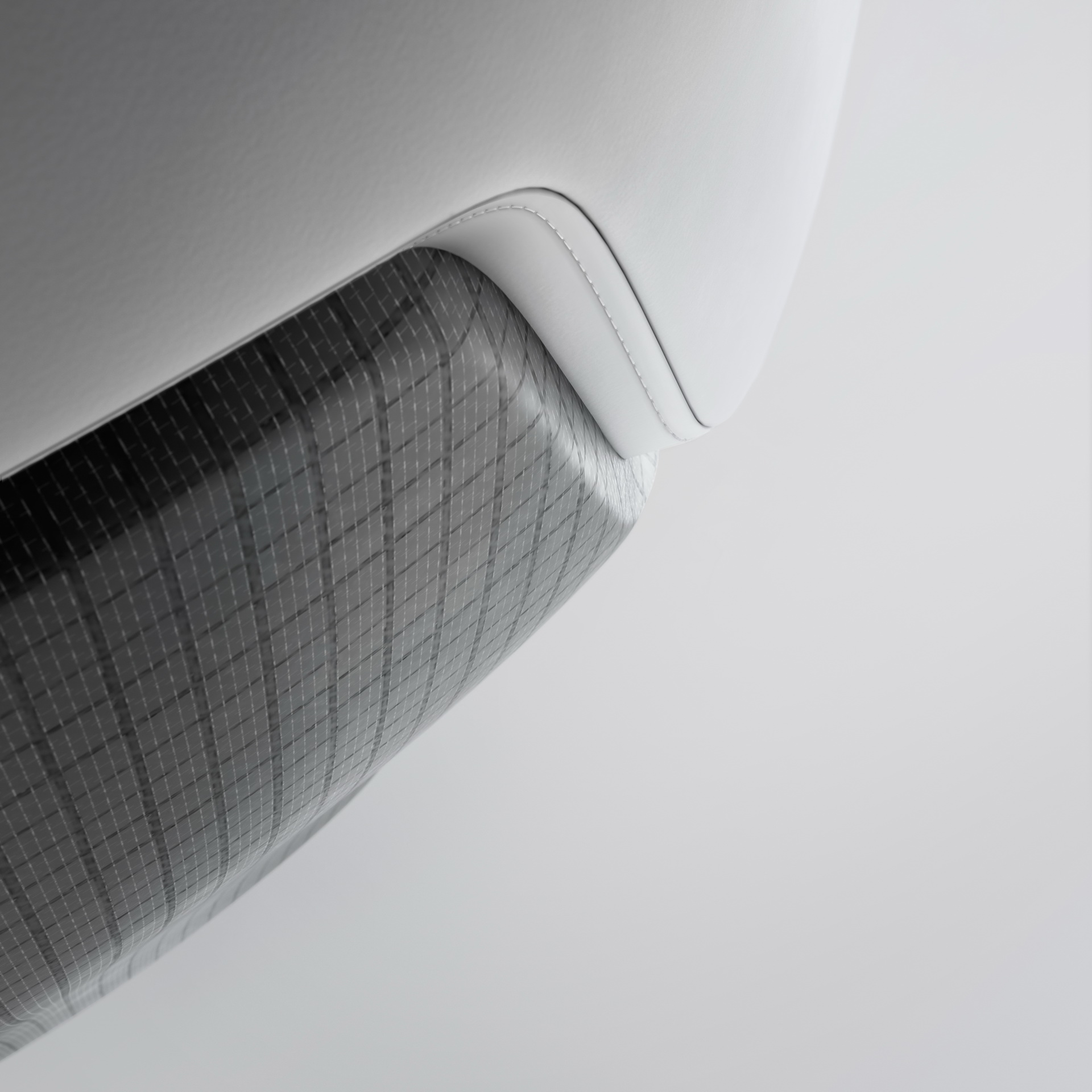

For the seats, a 3D-knit material can be implemented in a way that reduces waste and promotes recycled material sources. This works thanks to a single thread being used to produce the three-dimensional individual components, while the base material is 100% recycled yarn derived from PET bottles.

Both the wine and fishing industries can contribute too, with cork and fishing nets being recycled and incorporated within car interiors. For example, waste material from the cork manufacturing process can be integrated into PVC interior componentry, while recycled Nylon 6 (derived from discarded fishing nets) can be turned into woven carpets.

“Importantly, we don’t need to sacrifice design and luxury with these materials,” said Polestar design boss Maximilian Missoni. “If anything, they enable even more premium, cutting-edge, modern and stylish executions which elevate our design-led products. It also presents a positive challenge, giving new meaning to interior design. We are able to derive new aesthetics from new contexts and technologies, allowing society to move on.”