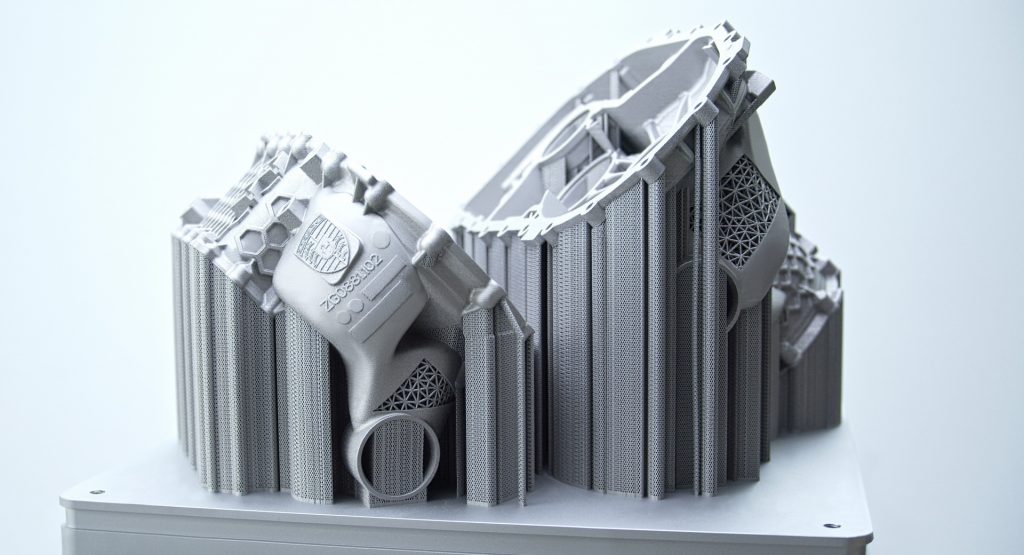

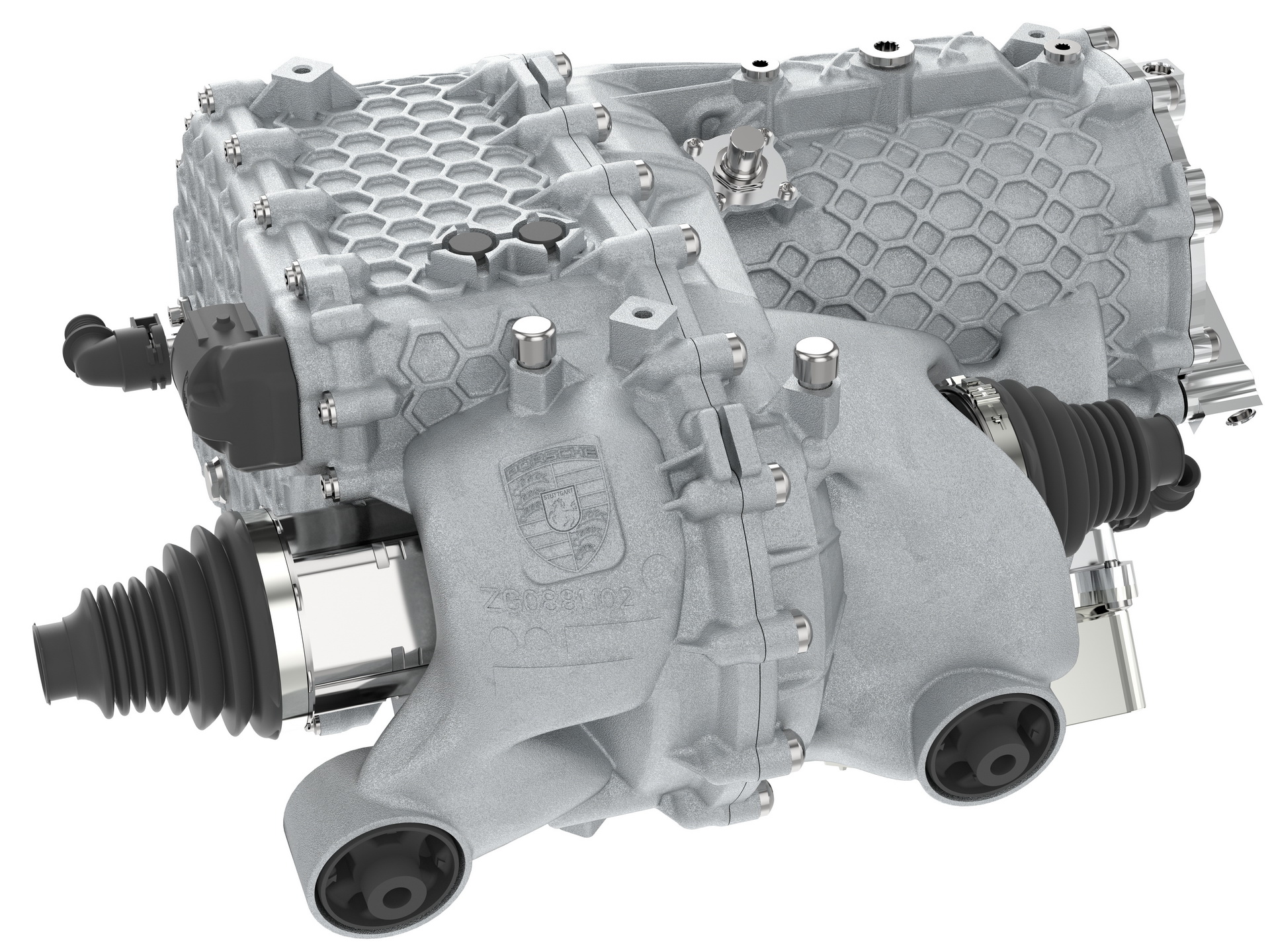

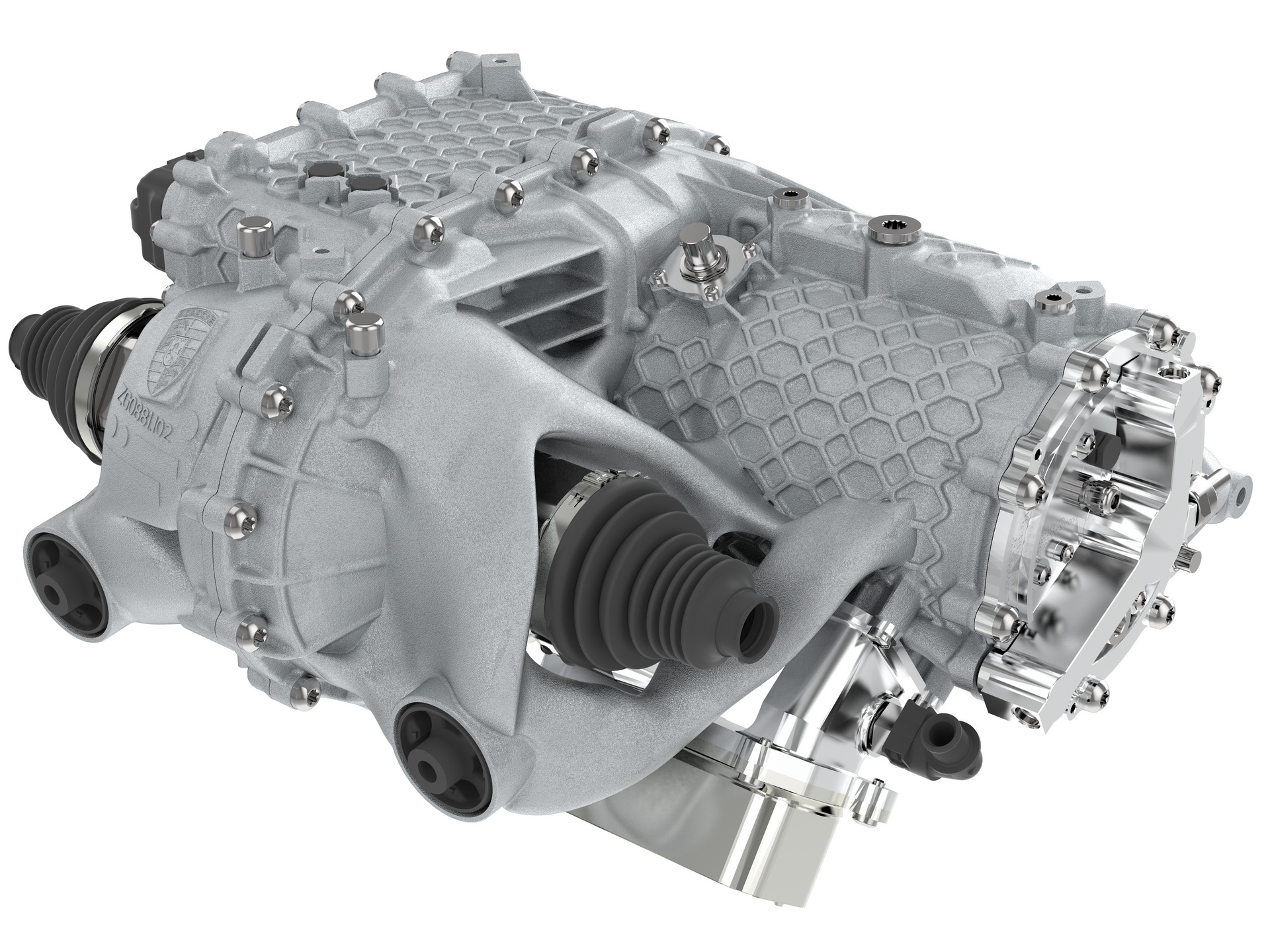

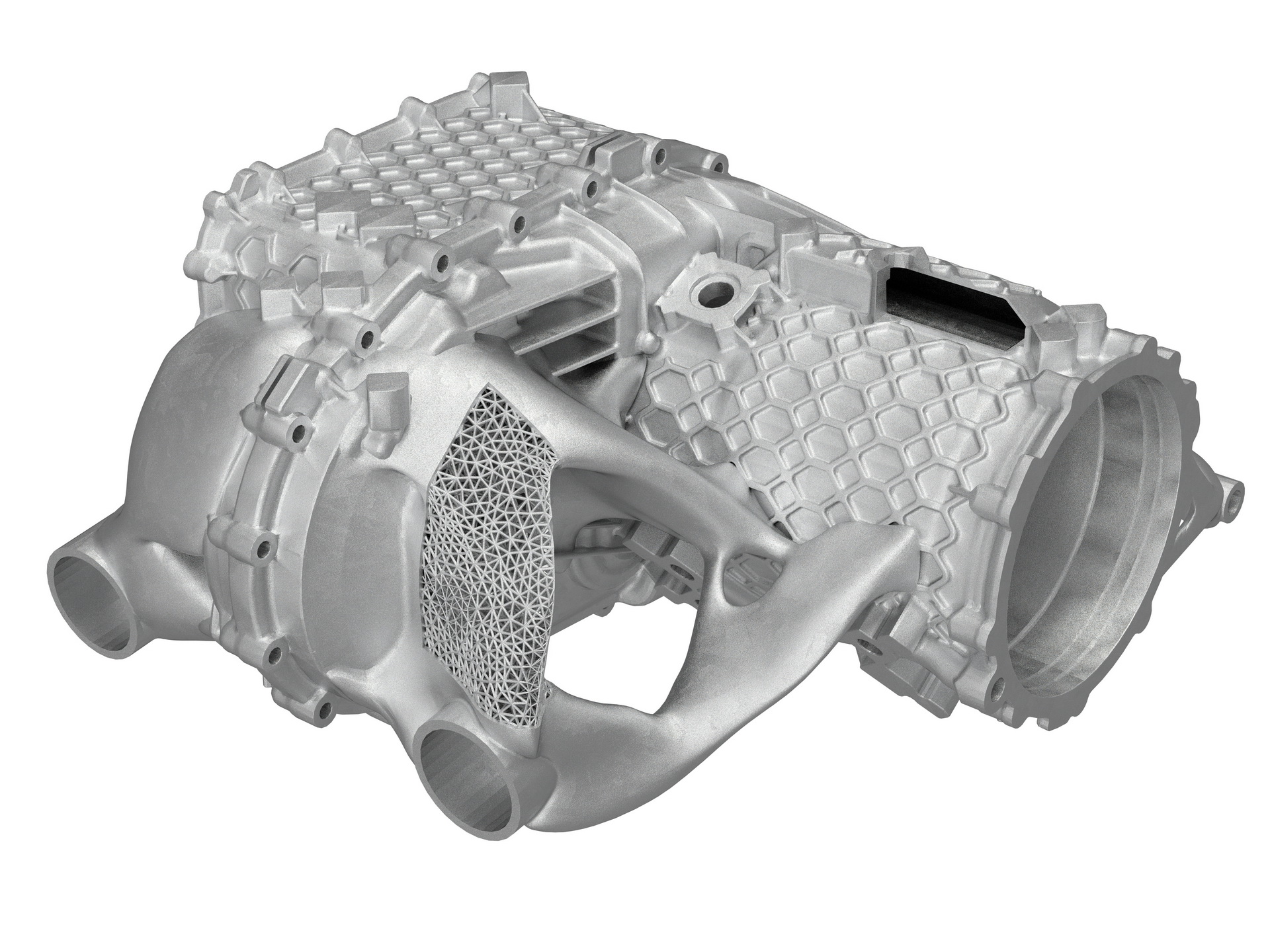

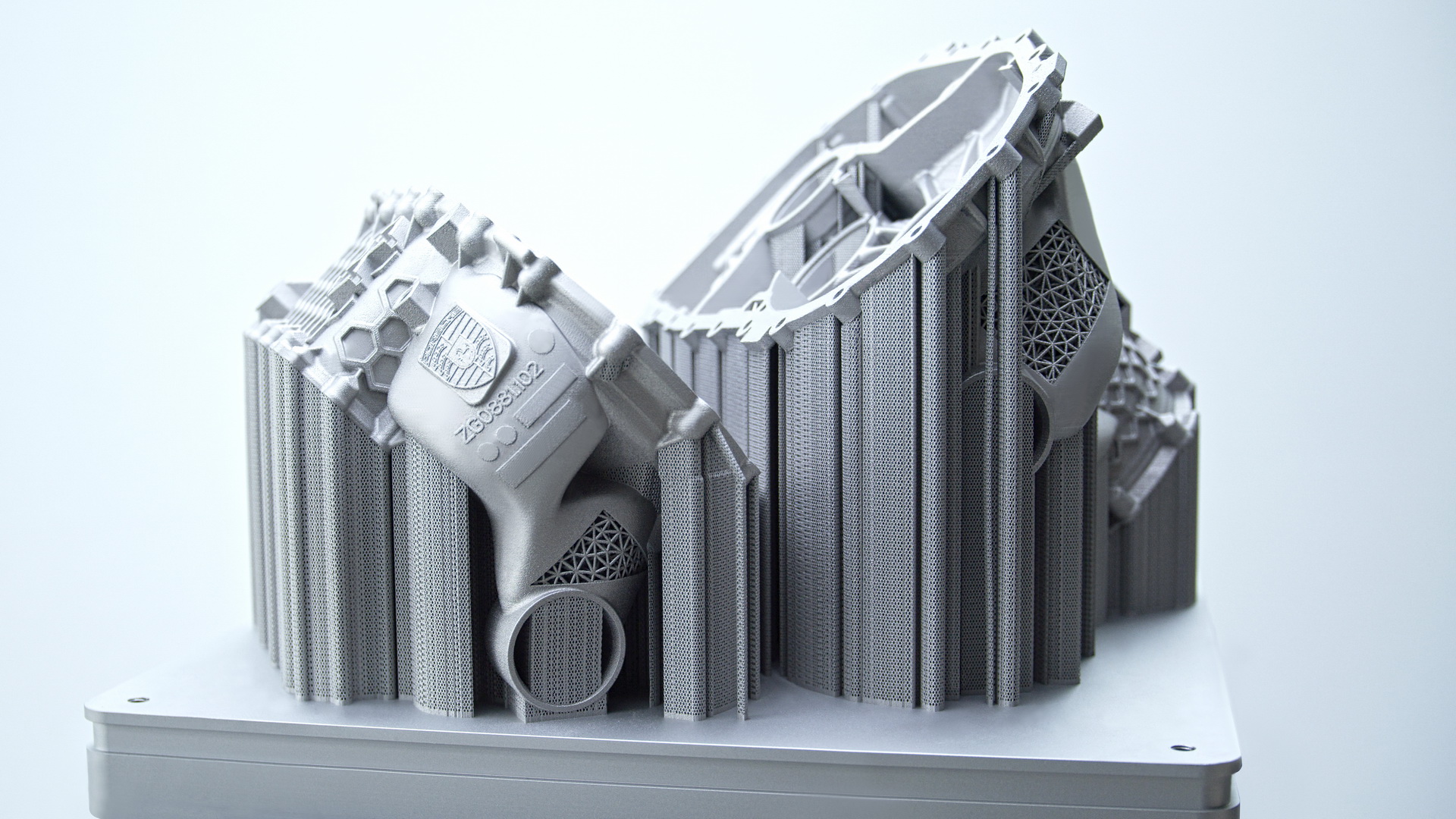

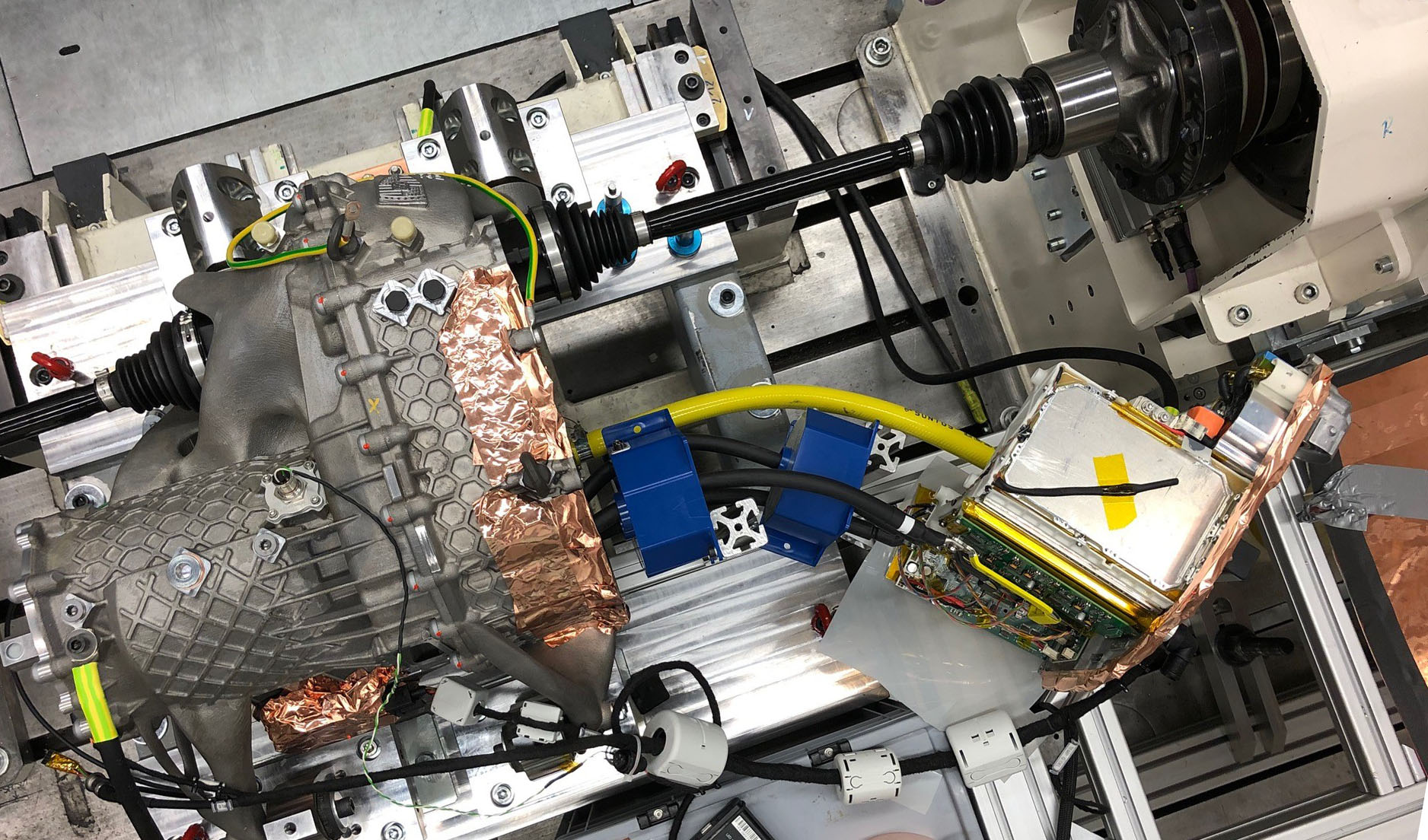

Porsche has built its first ever complete housing for an electric drive unit (engine and gearbox) using 3D printing. The unit even passed quality and stress tests without any issues, proving that this technology is viable for consumer products.

The prototype unit’s additively-manufactured alloy housing is more lightweight than a conventionally cast part, reducing the overall weight of the drive by roughly ten percent.

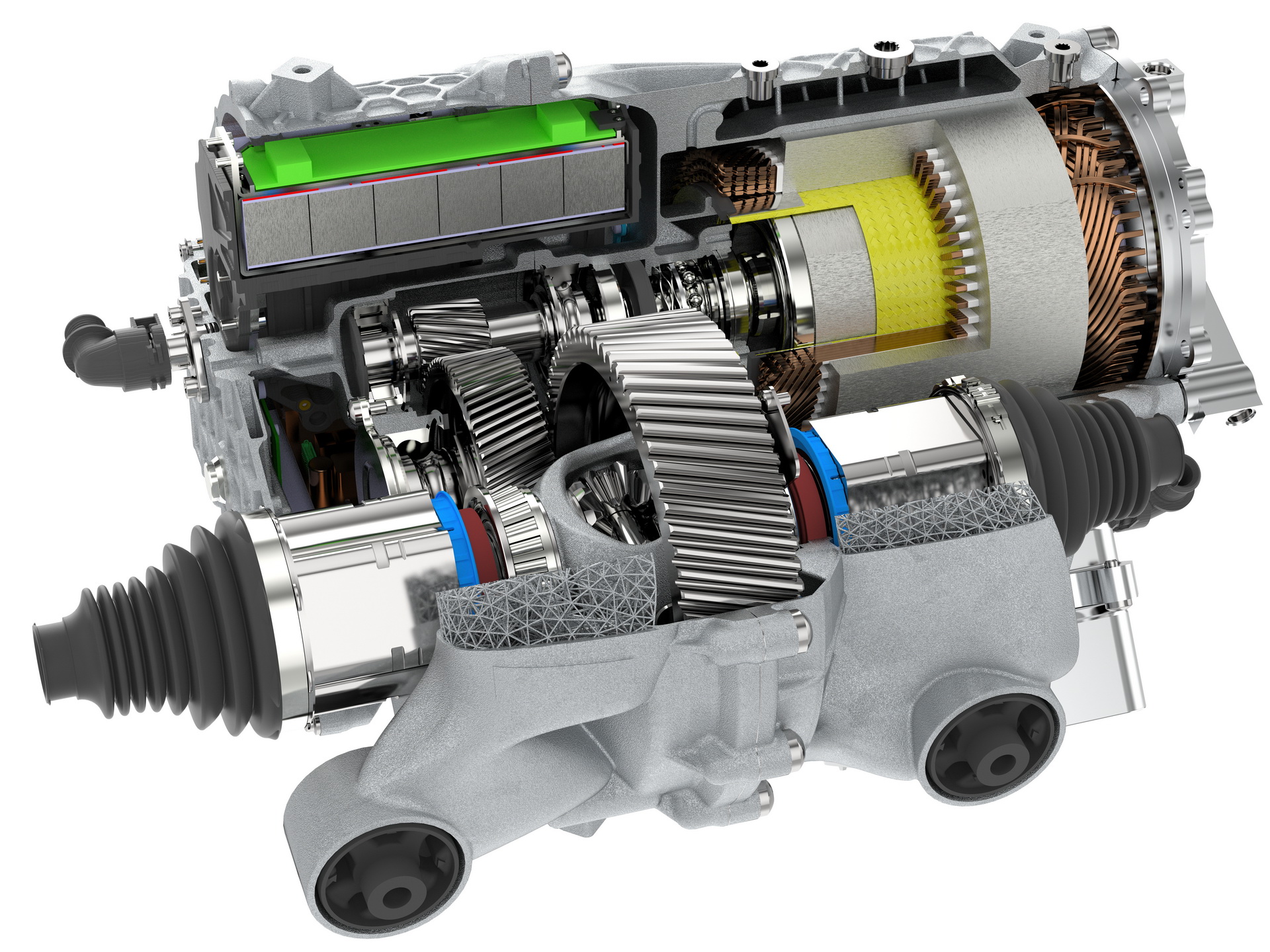

Meanwhile, stiffness in highly stressed areas has nevertheless been doubled, thanks to special structures made possible by 3D printing.

Read Also: Porsche Digital To Use AI Tech For Noise Detection

“This proves that additive manufacturing with all its advantages is also suitable for larger and highly-stressed components in electric sports cars,” said Falk Heilfort, Project Manager in the Powertrain Advance Development department at the Porsche Development Centre in Weissach.

Another advantage to using this technology is the fact that many functions and parts can be integrated, thus reducing assembly work which can benefit the overall quality of the part itself.

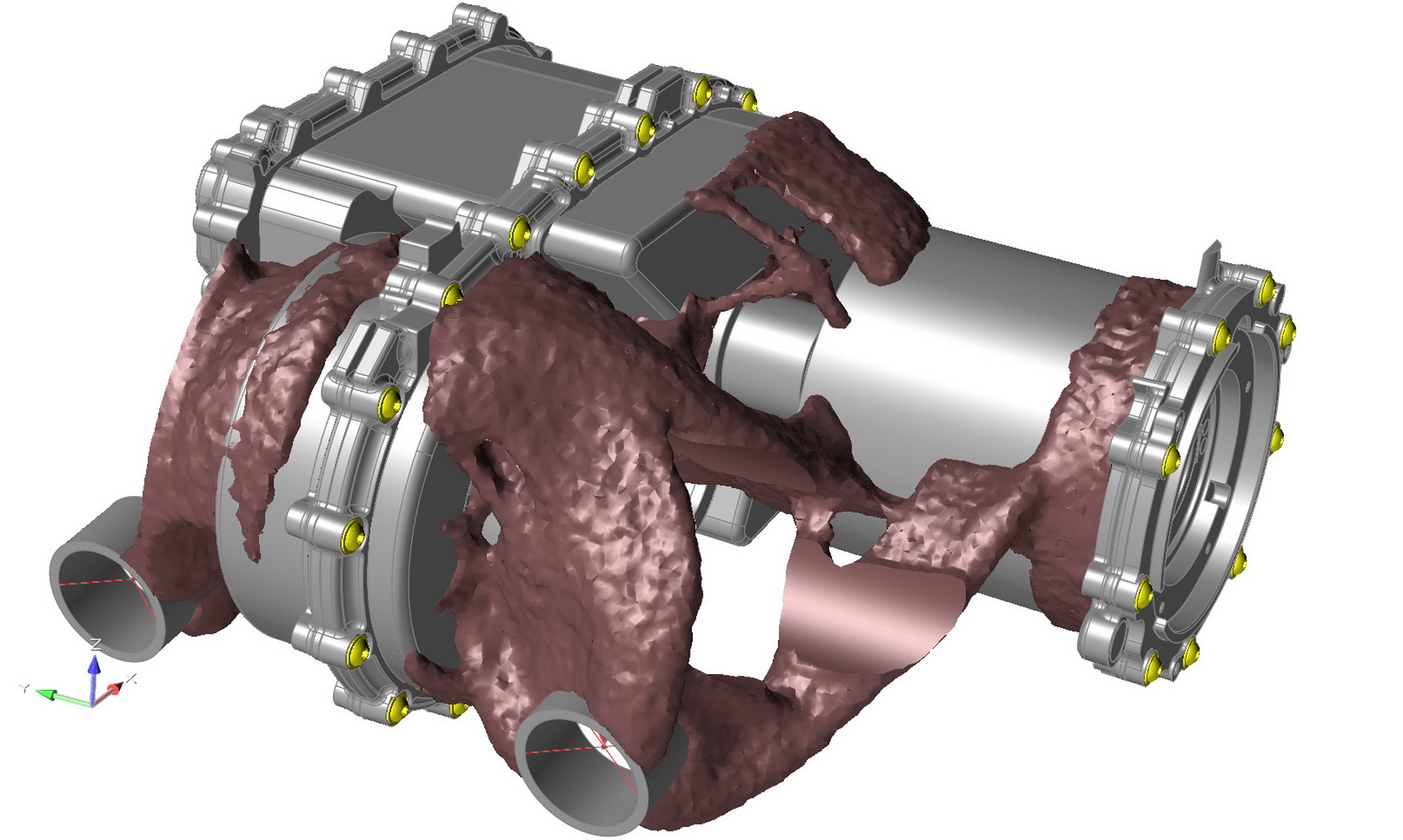

The German sports car-maker is intensively driving forward the use of additive manufacturing for high-stress parts – a few months ago, Porsche tested out printed pistons in the 911 GT2 RS. Meanwhile, for an electric drive unit, the same housing can hold the electric motor and the downstream two-speed gearbox, situated on the front axle.

“Our goal was to develop an electric drive with the potential for additive manufacturing, at the same time integrating as many functions and parts as possible in the drive housing, saving weight and optimising the structure,” added Heilfort.

The weight of the housing part alone was down by some 40 percent, while the integration of parts reduced assembly work by around 40 work steps – the equivalent of cutting production time by 20 minutes. Then there’s the additional benefit of integrating the gearbox heat exchanger with optimized heat transmission, which improves the cooling of the drive as a whole.

Porsche will keep exploring this manufacturing technology as it could prove ideal for special and small series models, as well as motorsport applications.