BMW has developed a new paint application that sounds like a win-win for the environment and enthusiasts. The overspray-free technology also allows vehicles with intricate designs, including two-tone offerings, to be painted faster and cheaper.

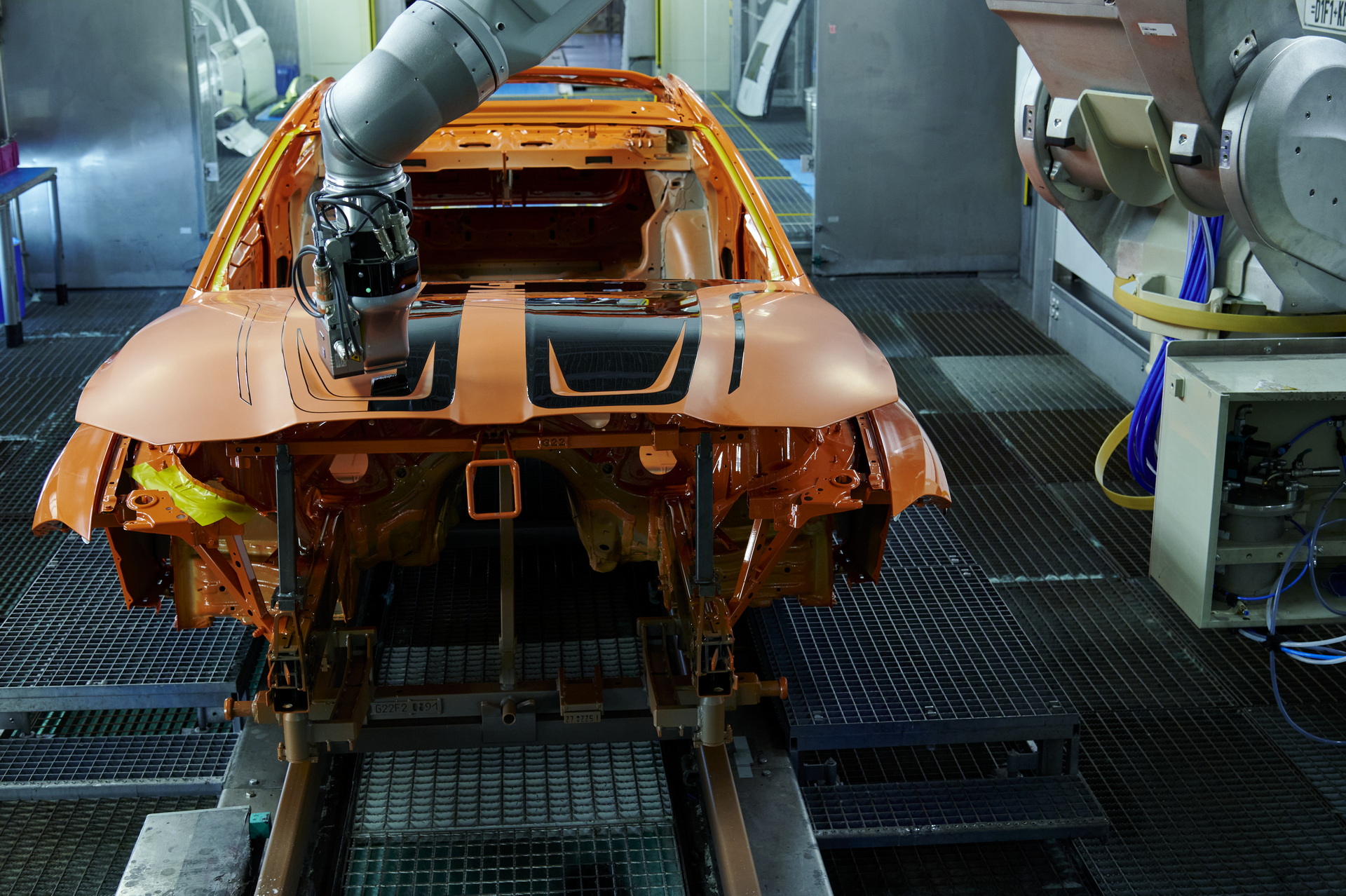

The new process is being called EcoPaintJet Pro, which allows it to apply paint more precisely. Rather than using a paint gun that atomizes paint with a rotating bell that spins at 35-55,000 rpm and adheres to the surface electrostatically, the new method works without electrostatics, relying instead on jet application.

The process uses an orifice plate that enables high edge definition with a variable thickness of between 1 mm and about 50 mm (0.039 to 2 inches). That allows BMW to apply colors so precisely that it can paint a two-tone paint job without masking, such as you might want on a hood with racing stripes.

Read Also: Take A Look Inside Lamborghini’s All-New, State-Of-The-Art Paint Shop

According to BMW, the individualization options are “virtually limitless,” because you don’t need to have people masking body panels manually. Instead, you can just program a design into the computer and it paints onto the body panels like an inkjet printer.

By saving paint and personnel time, that saves money, allowing BMW to offer personalized designs more widely. Using less paint also means less waste. Less air is also required, which means that the paint shop can save electricity because it doesn’t have to compress that air. The brand estimates that this new process will actually save around 6,000-megawatt hours of power and reduce the paint shop’s carbon footprint by nearly 2,000 tonnes per year.

To show it all off, BMW is testing the possibilities of its new process with a small series of M4s that will initially be used in its own fleet and is scheduled to be introduced in 2022.

“We expect the highest standards of efficiency, sustainability, and digitalization from our production,” said Milan Nedeljković, head of production at BMW AG. “This smart painting technology meets all the requirements for an innovative production process and also offers unique customer benefits.”