A shortage of wiring harnesses continues to hurt the automotive industry and has prompted some to suggest it could speed up the adoption of electric vehicles.

Many of the industry’s wire harnesses are manufactured in Ukraine but production has been crippled since the outset of the war. This has prompted some carmakers to shift production to other countries. For example, Mercedes has started to source harnesses from Mexico while some suppliers in Japan have added capacity in Morocco. Production lines are also being established in Tunisia, Poland, Serbia, and Romania.

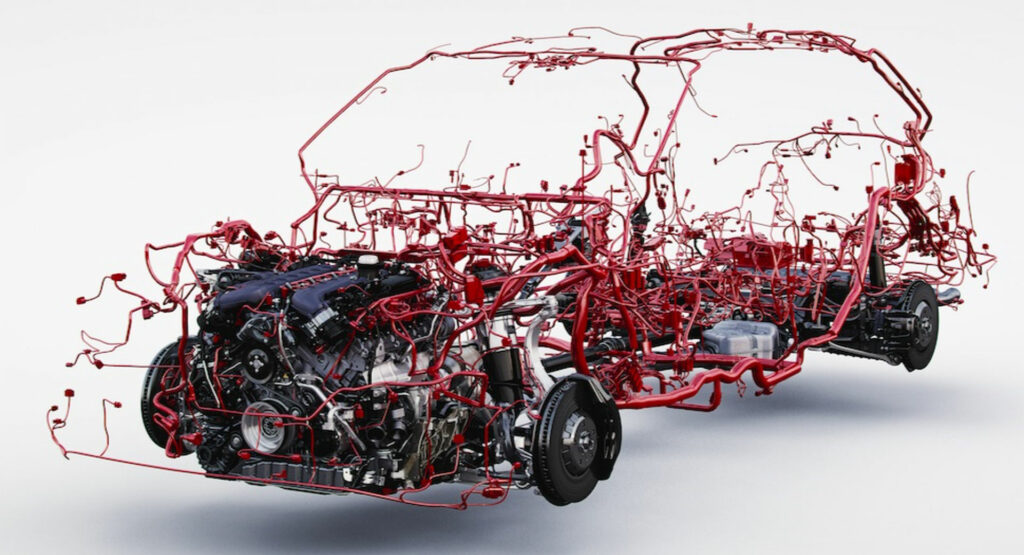

The average internal combustion engine vehicle has up to 3.1 miles (5 km) of cables that are bundled together into a harness. Speaking with Reuters, Bentley chief executive Adrian Hallmark said the British car manufacturer had feared losing 30-40 percent of its car production for 2022 had it been unable to find new suppliers.

While Hallmark said Bentley was able to find alternative production sources, it has increased its focus on developing a simple harness for EVs similar to those used by Tesla. These harnesses can be made in sections on automated production lines. They are also lighter than traditional harnesses.

Read Also: Volkswagen Delays Launch Of ID.5 To May Due To Lack Of Wiring Harnesses

“The Tesla model, which is a completely different concept of wiring, we couldn’t change to that overnight,” Hallmark acknowledged. “It’s a fundamental change in the way that we design cars.”

According to wire and cable supplier Leoni, many car manufacturers are working with it on automated solutions for EV wire harnesses. In particular, the company is developing modular harnesses that will be split into six to eight parts, allowing for automated production. BMW is one of the car manufacturers looking to use modular harnesses like these in the future.

A Californian startup by the name of CelLink has recently developed an automated, flat “flex harness” that is already being used by a number of electric vehicles. The company’s production lines can switch between different harness designs in just 10 minutes. According to chief executive Kevin Coakley, it also takes CelLink just two weeks to ship redesigned harnesses compared to up to 26 weeks for changing a conventional wire harness.