There’s a good chance that more than one wealthy, German Mercedes S-Class owner will arrive at the ski slopes this year having cruised down the autobahn to get there with his car’s DrivePilot autonomous function engaged.

But what he probably wouldn’t know is that Lidar technology very similar to the kind enabling his S-Class to drive by itself is also used to perfect the shape of the ski slopes he’ll be spending the next week sliding down.

I came across this fact while trying to find out more about the strange-sounding Pistenbully tracked snow plough that hospitalized Marvel Hawkeye star Jeremy Renner earlier this week. Renner had got out of the vehicle while trying to unstick a car stuck in snow at his Utah home, when the machine rolled forward and drove over him causing serious injuries to his chest and legs.

Sleuths at Jalopnik worked out that Renner’s snowcat, which is the generic name for these monsters, was an older model of the Kässbohrer-built PistenBully, possibly a PB240D from the 1980s. But what caught my attention on the maker’s own website was the hugely sophisticated technology found in the latest examples. I mean, just look at the number of switches inside the cabin (pictured below). It makes even your average F1 steering wheel look like a paragon of simplicity.

Related: Mercedes Becomes First Brand Approved For Level 4 Self-Driving In Germany

I knew farm machinery was highly automated and packed with computer power, but I presumed those snowcat machines you see on ski slopes just relied on the driver’s eye and experience to work out where to push the snow and keep ski slopes covered with enough of the white stuff. And I was wrong.

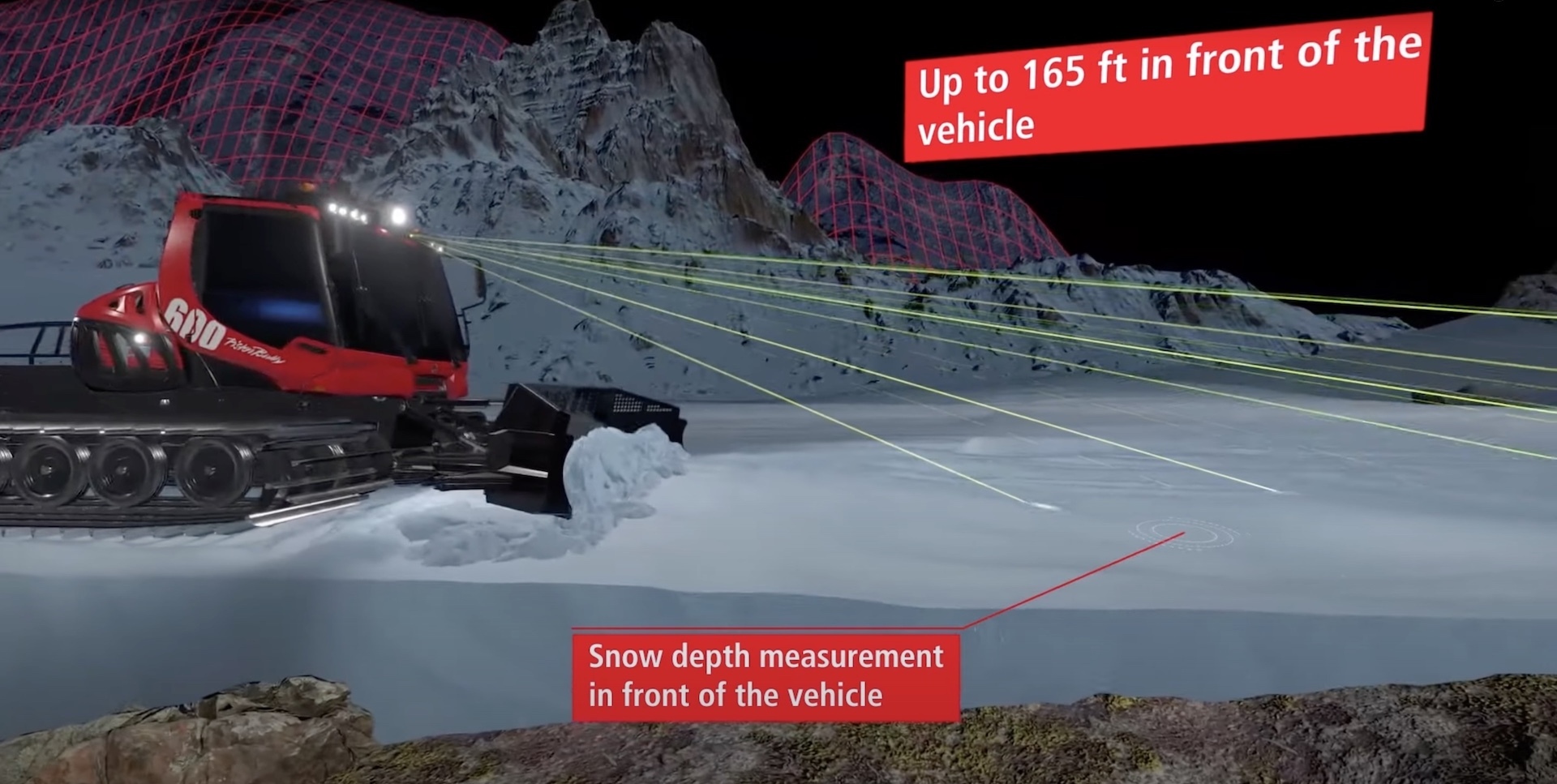

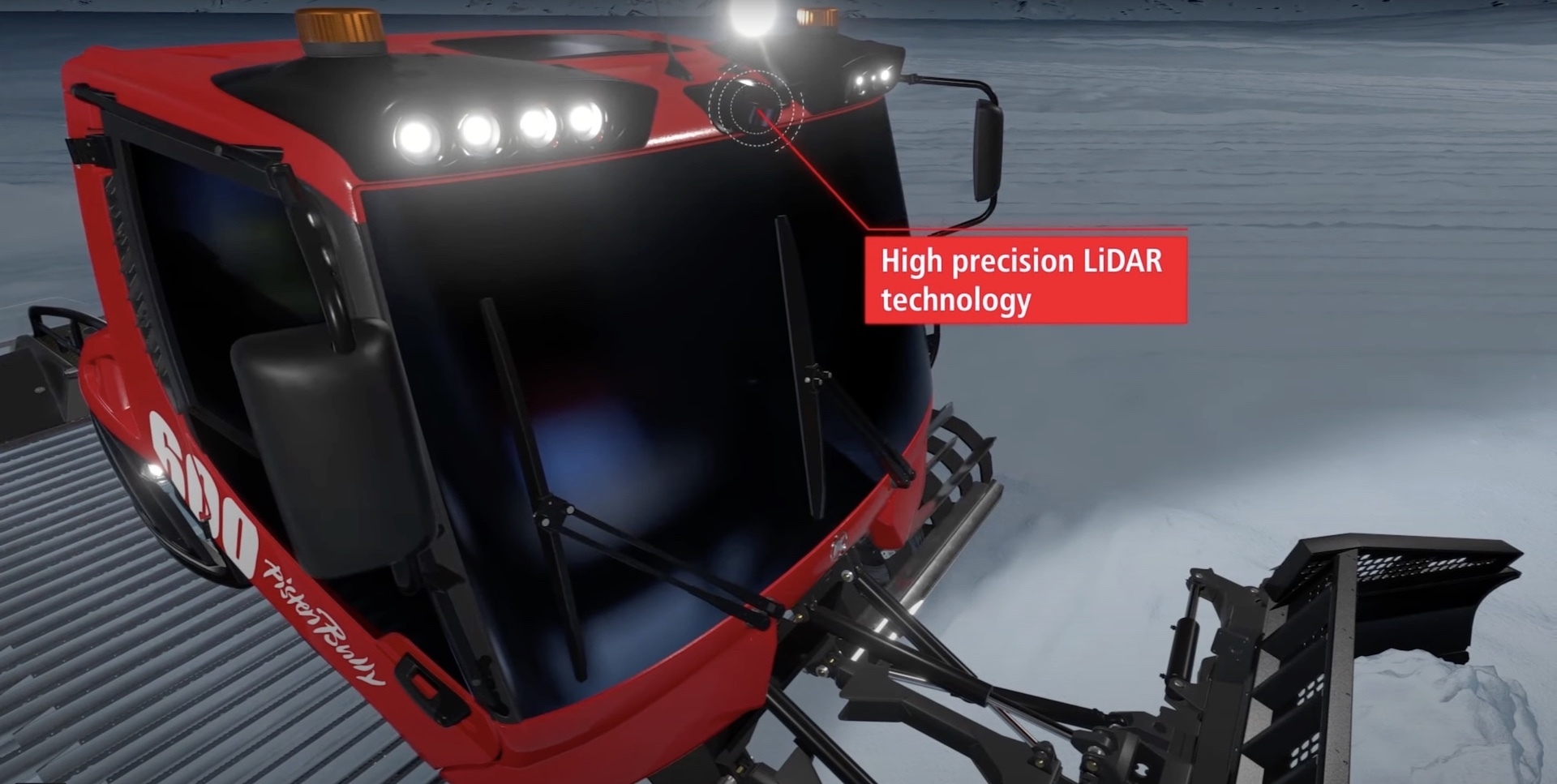

Some of the latest snowcats from Germany’s PistenBully feature something called Snowsat Lidar to measure the depth of the snow and help the driver work out where to move it from and to. In the past, drivers could only rely on snow depth measurements taken under the vehicle, meaning they had no idea what the snow conditions ahead were like until they were literally on top of them. But the Lidar tech allows them to see up to 165 ft (50 m) in front of the plough, and even to the sides of the intended direction of travel.

A sensor on the roof capturing 200,000 data points per second allows the computer to see an area measuring 28,000 sq ft (2,600 sq m), showing high spots as green, and thin patches as red, on one of the in-cab monitors. The company behind the Snowsat technology says it makes “grooming” ski slopes less time consuming, which also reduces costs and carbon emissions. It’s also safer for operatives because it shows cliffs and rocks, and allows work to continue even when human visibility is hampered by extreme weather.

Unlike the Mercedes S-Class with its Lidar-enabled Level 3 autonomy, however, cruising in a Lidar-equipped PistenBully isn’t a hands-off affair. But only a fool would bet against that changing within the next few years.