Pothole season is well underway and Toyota has provided a glimpse at how they test their vehicles to cope with these familiar road hazards.

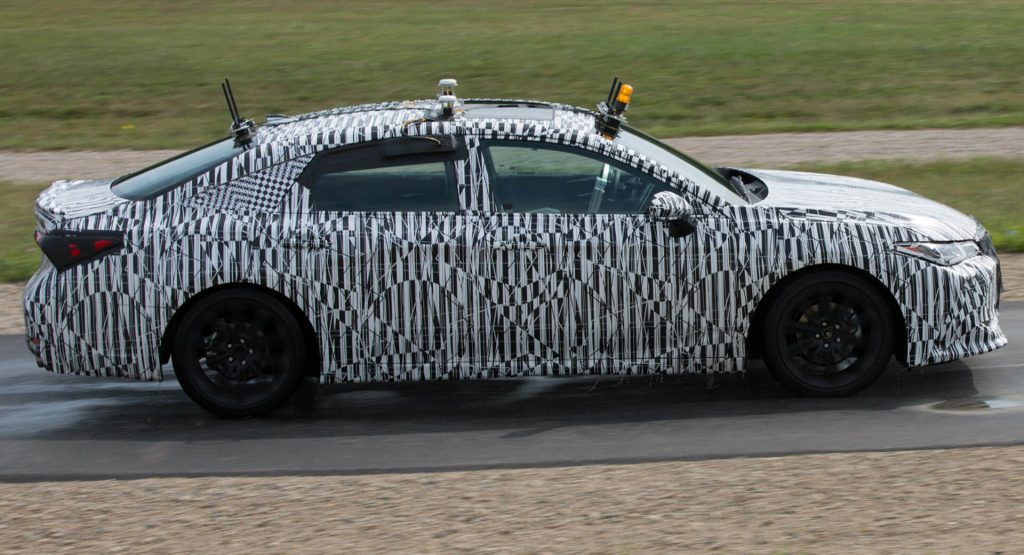

As part of the company’s “rough road durability” testing, US-spec models are subjected to a specially designed course which is located in Michigan. While many courses are designed to test a car’s handling and performance, this is a mini highway to hell as it features purpose-built “potholes, dips and other defects.” Engineers used to have to drive over these imperfections repeatedly but, thanks to advances in technology, this is no longer necessary.

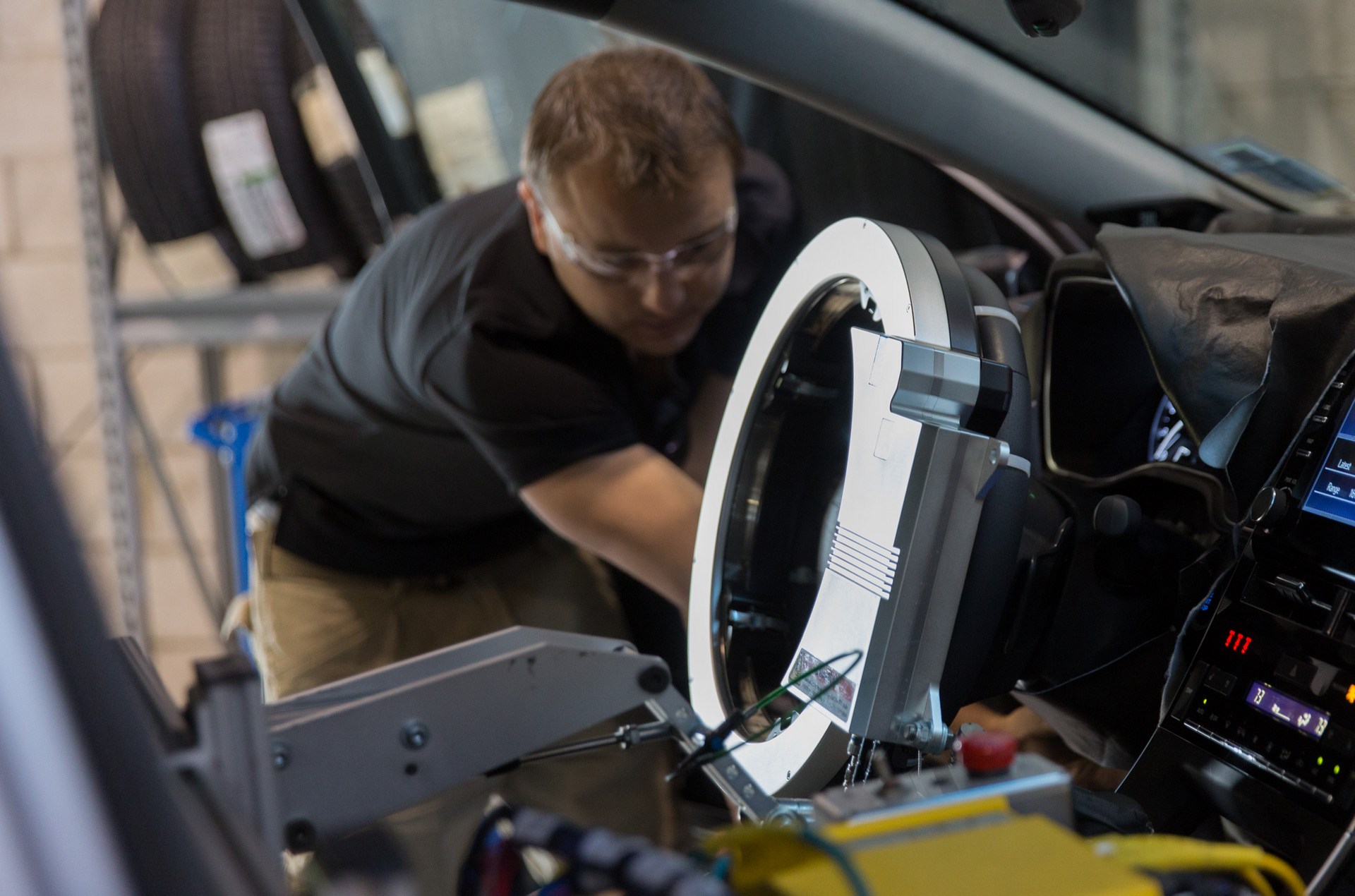

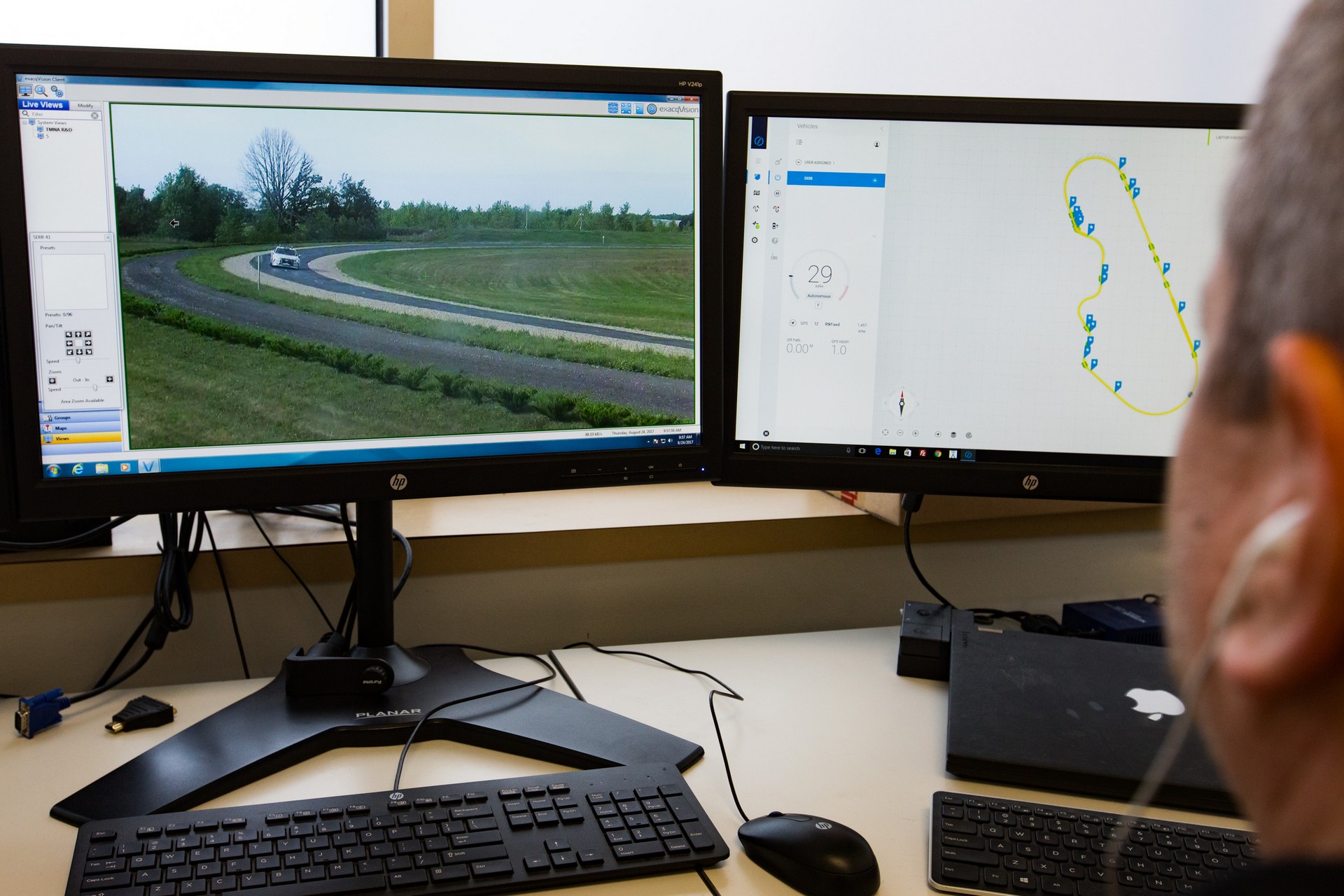

The 2019 Avalon was the company’s first vehicle to complete the tests without a human driver as engineers installed an assortment of computers, actuators and other components to enable the car drive itself. Toyota suggests this wasn’t exactly a high-tech process as the team didn’t use any cameras, sensors or radar systems. Instead, they used “GPS-guided path control” which has an accuracy of 2cm (0.78 inches).

The automated testing was a resounding success as Toyota says the car was able to stay on course more consistently. The technology also allowed the tests to be completed much quicker than before as the company used to swap out human drivers every 30-40 minutes.

According to Avalon chief engineer Randy Stephens, “This not only saved the engineers and technicians from having to endure the grueling ride, it also provided a more accurate test cycle.” Stephens went on to say “The system was proven during Avalon development and we plan to use it during all future North American vehicle development cycles.”