Teaching is a challenging task, particularly when it comes to robots. Traditionally, instructing a robot on how to execute a new task required the creation a complex piece of code, which the robot would then rigorously adhere to. However, Toyota has now devised a method to swiftly and effortlessly “show” a new task to a robot, eliminating the necessity to generate any new code tailored to that behavior.

Working with Columbia University and others, the Toyota Research Institute (TRI) used a generative-AI approach called Diffusion Policy to find a new way to teach robots new behaviors at a much faster rate than was previously possible.

“The tasks that I’m watching these robots perform are simply amazing – even one year ago, I would not have predicted that we were close to this level of diverse dexterity,” says Russ Tedrake, the VP of Robotics Research at TRI. “What is so exciting about this new approach is the rate and reliability with which we can add new skills.”

Read: These Robots Can Snatch Your Illegally Parked Car From The Tightest Space

The technology requires a human to use a telerobotics kit to “show” the robot how to perform a task. Using levers and handles that provide the human with haptic feedback of what the robot is feeling, the person can effectively control it directly.

According to Tedrake, it’s not uncommon for Toyota’s researchers to teach a robot a new behavior in the afternoon, allow the robot to learn throughout the night, and witness the robot’s flawless execution of the new task the following morning.

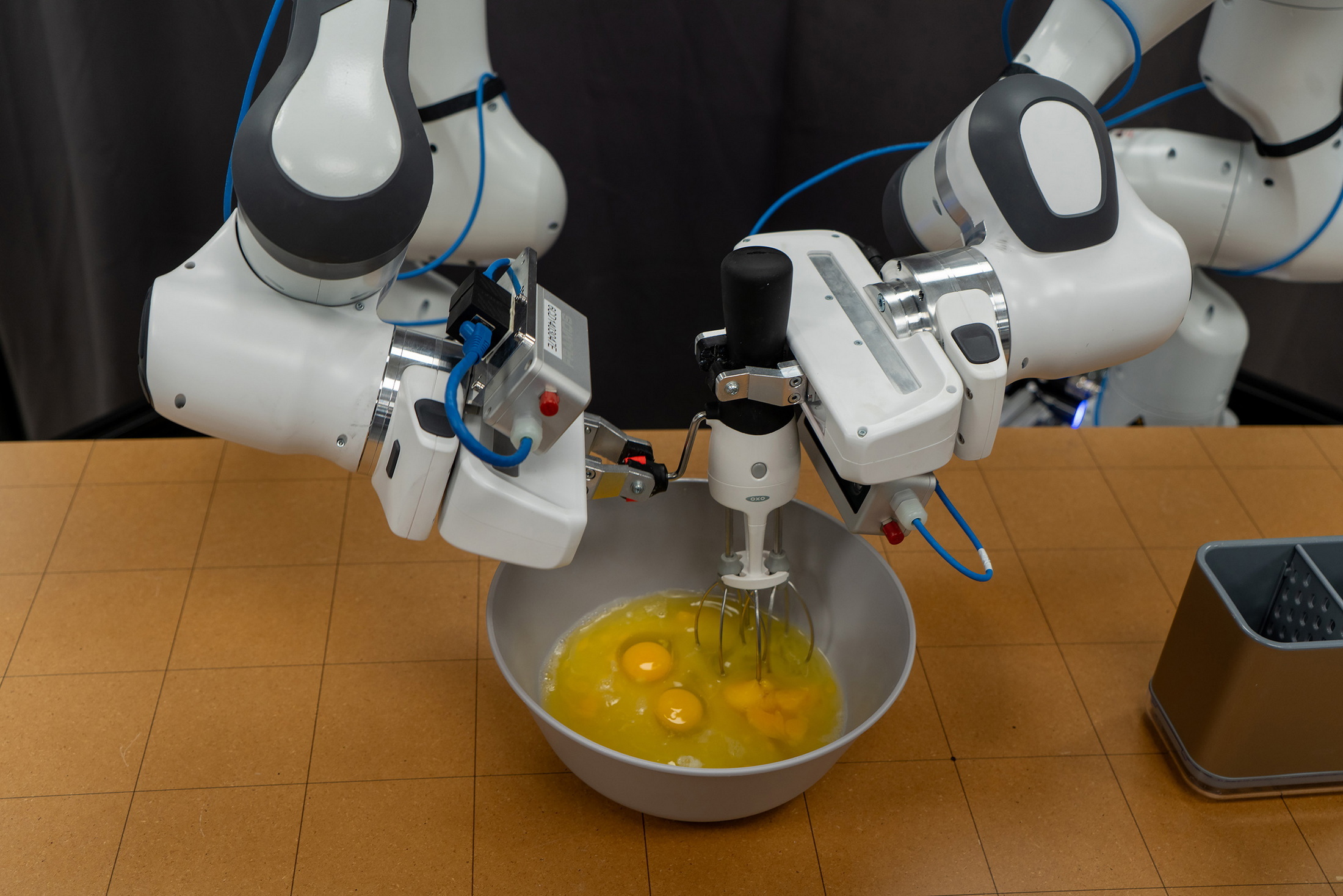

“Because these skills work directly from camera images and tactile sensing, using only learned representations, they are able to perform well even on tasks that involve deformable objects, cloth, and liquids — all of which have traditionally been extremely difficult for robots,” said Tedrake.

Working in much the same way as the Large Language Models that power conversational AI, the technology has already allowed Toyota to teach its robots more than 60 difficult skills that require high amounts of dexterity.

These expand beyond the “pick and place” tasks that similar robots were previously capable of. They include pouring liquids, using tools, and manipulating deformable objects. TRI hopes to teach the robot hundreds of skills by the end of the year, and at least 1,000 by the end of 2024.

While it does not specify what the technology will be used for, the addition of dexterous robots that can easily be taught new skills would likely be welcome in many manufacturing plants.

“Our research in robotics is aimed at amplifying people rather than replacing them,” said Gill Pratt, CEO of TRI and Chief Scientist for Toyota Motor Corporation. “This new teaching technique is both very efficient and produces very high performing behaviors, enabling robots to much more effectively amplify people in many ways.”