It’s hard not to be impressed by the engineering work that goes on at Koenigsegg. Given that the Swedish firm remains a small company and is not part of a larger automotive conglomerate, it could be forgiven for relying heavily on outside suppliers for big components like powertrains all the way down to smaller parts. That’s not the way Koenigsegg does business.

Led by Christian von Koenigsegg, the brand has made a name for itself not only with its hypercars but also by pushing the boundaries of automotive powertrains as we know them. In addition to developing a camless turbocharged four-cylinder with over 600 hp, it has also made a gearbox unlike any other; the Light Speed Transmission with seven clutches and no traditional selector forks, collars, or synchronizers.

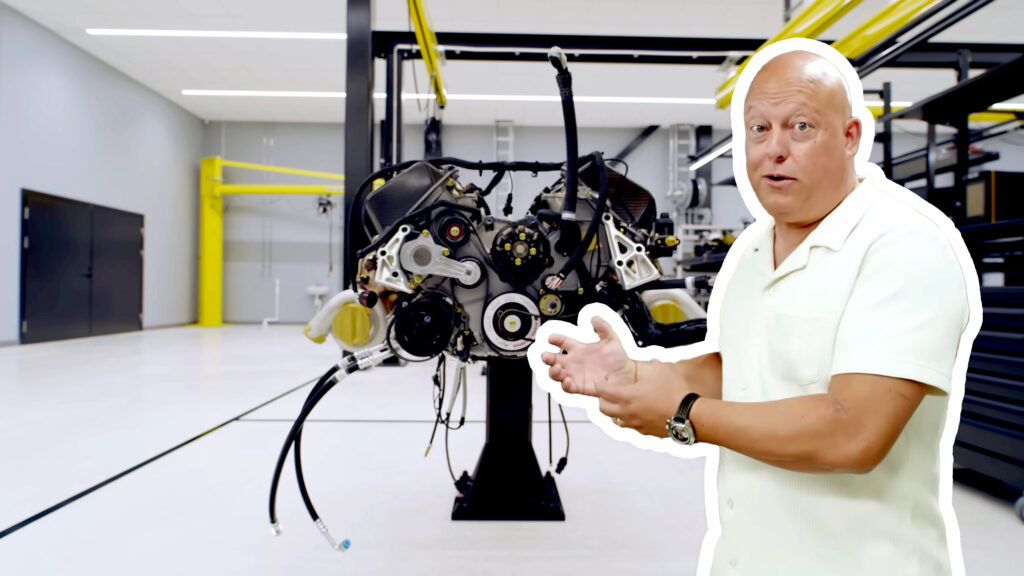

To give us an idea of how this transmission is created, Koenigsegg has put together an in-depth video filmed from inside the facility where it is made. This video doesn’t just provide us with an excellent understanding of the Light Speed Transmission but also the 5.0-liter twin-turbocharged V8 of the Jesko. It takes a single worker one full week to assemble an engine. The special version of this V8 used by the Gemera is also assembled at the same site.

Watch: This Is How The Koenigsegg Gemera’s Advanced Hybrid Powertrain Works

The engine of the Jesko is related to that of the Agera, but it has been extensively modified and includes four valves per cylinder and a 180-degree flat-plane crankshaft. Fueled with E85, the engine churns out a monumental 1,600 hp, so it comes as no surprise that all of the internal parts have been designed to withstand massive amounts of power while remaining reliable. Making the engine all the more impressive is the fact that it weighs less than 200 kg (440 lbs) and has been designed to meet all emissions requirements around the world.