The first-generation Toyota Prius made its debut nearly 30 years ago. As a result, many of these vehicles have either already reached the end of their lifespan or are approaching it, making them suitable candidates for recycling. The batteries that once powered these early hybrids will find a new purpose in Toyota’s upcoming generation of electrified vehicles, thanks to a recently established partnership with Redwood Materials.

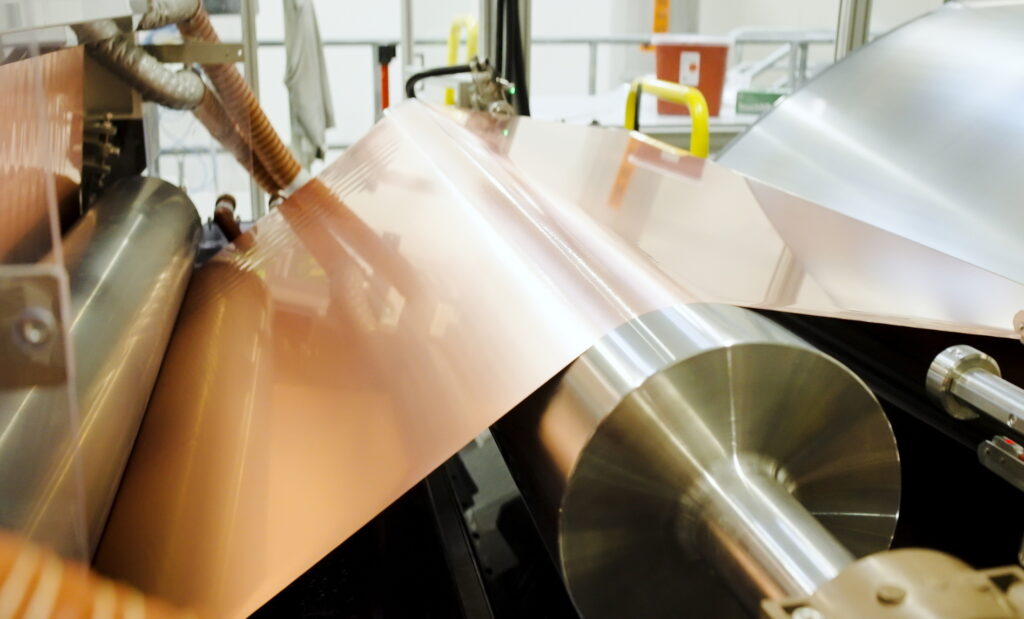

Toyota previously agreed to supply the automotive recycling company with its end-of-life battery-powered vehicles. Now, thanks to a new deal, the automaker will also source cathode active material and anode copper foil from the company.

“Today, in collaboration with Redwood Materials, Toyota is making a decisive move toward a sustainable future,” said Cal Lankton, Redwood Materials’ Chief Commercial Officer. “They’re not only working to ensure responsible end-of-life management for their electric vehicles but also planning to build their next generation of EVs, in part, by using sustainable and domestically manufactured battery components.”

Read: Redwood Materials Gets $1 Billion In Fresh Funding To Grow EV Battery Recycling Business

Toyota expects the battery lifecycle ecosystem it is forming with Redwood to include the recycling, re-manufacturing, and repurposing of around 5 million operating units. Much, though not all, of that recycled material will come from its own fleet of hybrid vehicles.

With a significant portion of Priuses being sold in California, many will end up at Redwood’s Nevada recycling facility once they reach the end of their lives. Parts manufactured at the facility will then make their way to Toyota’s upcoming battery manufacturing facility in North Carolina.

The automaker emphasizes that this decision will aid in reducing production costs and localizing its supply chain. Beyond the environmental benefits, this move could potentially make Toyota vehicles eligible for tax credits in the United States.

“We’re thrilled to be procuring critical battery components and materials to filter into our battery ecosystem,” said Sean Suggs, president of Toyota’s North Carolina battery plant. “We’ll continue to work toward the sourcing and recycling of battery materials here in the United States to maximize these precious resources and reduce our carbon footprint in the process.”