Science is a time-consuming process. From conceiving an idea to delving into the existing body of research on the subject and collecting all the necessary resources for testing, it can span several years. Consequently, groundbreaking advancements in crucial domains such as EV battery manufacturing often entail extended timelines. However, Microsoft claims that artificial intelligence (AI) and large-scale cloud computing already expediting this process.

Microsoft has detailed the narrative of how its Azure Quantum Elements (AQE), a platform combining high-performance computing (HPC) and AI technologies, aided the U.S. Department of Energy’s Pacific Northwest National Laboratory (PNNL) in identifying a new material blend with the potential to reduce the amount of lithium content in batteries. Now, before you get too excited, it’s important to note that despite the platform being named Azure Quantum Elements, quantum computing was not involved.

Lithium is a relatively rare, expensive and environmentally taxing material to mine. Moreover, batteries made from it are energy-dense, so when something goes wrong with one, it’s a big problem, as reports of EV fires have made it abundantly clear.

Read: Northvolt Develops Cobalt-Free Battery Cell That Could Unlock Cheaper, Cleaner EVs

Reducing the use of lithium in batteries is indeed a significant endeavor, but it’s also a challenging one. Typically, PNNL would have to review all the published research on battery materials to formulate hypotheses about alternative approaches.

However, in this case, PNNL used Azure to evaluate all the elements it thought might be workable, and from that the algorithm proposed 32 million potential inorganic materials. Then, the system was asked to eliminate all of the combinations were unstable, those that were too reactive, and, finally, it filtered for the results for their potential to conduct energy. Ultimately, the process cut the list of potential chemistries down from 32 million down to about 500,000 mostly new stable materials, then down to 800.

“Thirty-two million is something that we would never ever be able to do … Imagine a human sitting and going through 32 million materials and choosing one or two out of it. It’s just not going to happen,” said Vijay Murugesan, a staff scientist and a group leader for materials sciences at PNNL, according to The Verge.

The entire process took less than 4 days

At that stage, the PNNL team would traditionally employ high-performance computing, which is a more accurate but slower technology compared to AI. Eventually, they managed to narrow down the list of potential battery chemistries to just 23, five of which were already known. This process could have taken weeks, but with Azure, the team completed it in just 80 hours.

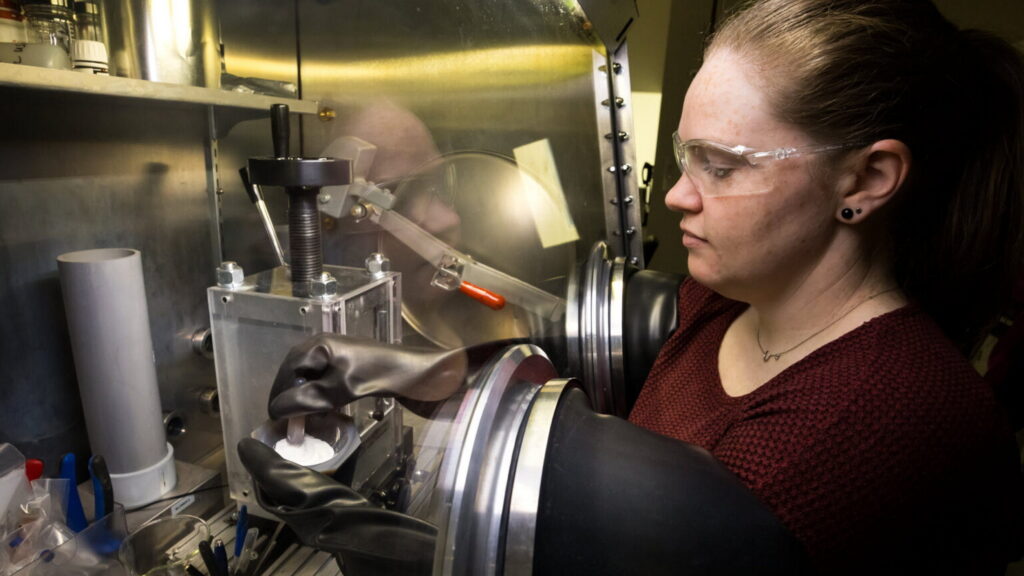

From that search, PNNL scientists synthesized one promising candidate that incorporates both lithium and sodium, along with other elements. According to Microsoft, the new material reduces the use of lithium by about 70% compared to existing lithium-ion batteries by substituting some lithium with more readily available sodium.

“This is important for many reasons” wrote Dr. Nathan Baker, Product Leader at Azure Quantum Elements. “Solid-state batteries are assumed to be safer than traditional liquid or gel-like lithium batteries, and they provide more energy density. Lithium is already relatively scarce, and thus expensive. Mining it is environmentally and geopolitically problematic. Creating a battery that might reduce lithium requirements by approximately 70% could have tremendous environmental, safety, and economic benefits.”

However, Brian Abrahamson, PNNL’s chief digital officer, cautioned that it is still early in the process, and the exact chemistry is subject to optimization. There’s a possibility that it might not perform as expected when tested at a larger scale.

Nevertheless, thanks to this research, the PNNL team is now looking at ways to use sodium to reduce the amount of lithium in batteries. It remains unclear if the results of this research will lead to better EVs, but the speed at which this research was conducted is what’s truly impressive.

“Irrespective of whether it’s a viable battery in the long run, the speed at which we found a workable battery chemistry is pretty compelling,” Abrahamson explained.

In the future, Microsoft envisions a world in which its AI could be trained to predict how materials might behave in a battery, allowing scientists to test them out virtually before even starting their own research in the real world. While that’s an exciting goal, the technology is already bearing fruit.